Understanding the size, weight, and height specifications of scissor lifts is crucial for selecting the right equipment for industrial tasks. This article explores key dimensions, load capacities, design standards, and maintenance practices. It aims to provide a comprehensive guide for engineers and safety professionals involved in scissor lift operations.

We will cover platform sizes, height ranges, safety regulations, and inspection protocols to ensure optimal performance and compliance. The information is structured to facilitate informed decisions in industrial environments.

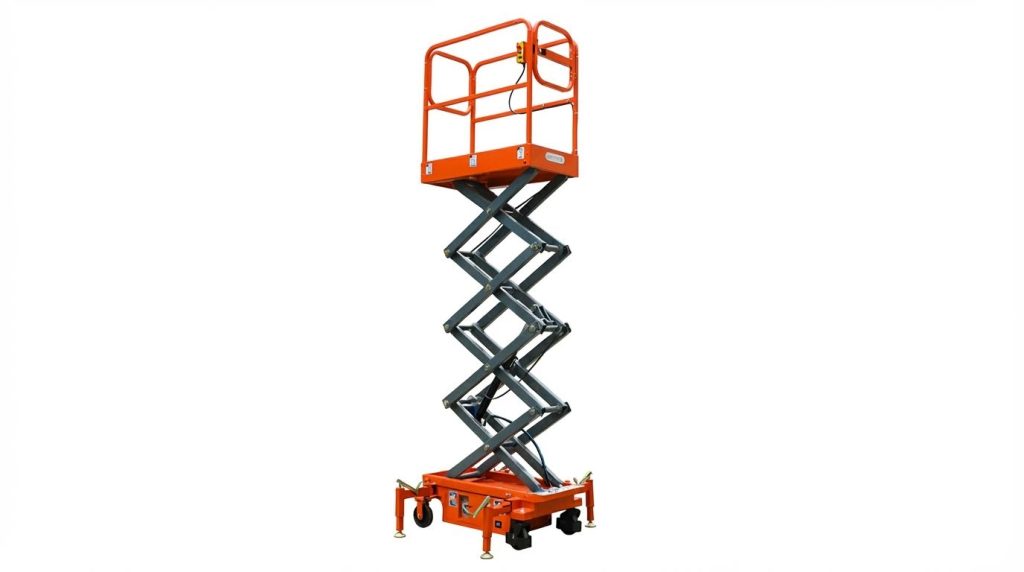

Key Dimensions and Load Capacities of Scissor Lifts

Typical Platform Sizes and Load Ratings

Scissor lifts typically feature platform sizes ranging from 0.9 m by 1.8 m up to 3 m by 7.5 m. Load ratings vary accordingly, with common capacities between 227 kg and 1,360 kg. These ratings depend on the platform size, structural design, and intended industrial applications. Selecting the appropriate platform size and load capacity ensures operational efficiency and compliance with safety standards.

Height Ranges and Working Envelope Specifications

Height ranges for scissor lifts usually extend from a minimum platform height of about 0.5 m to a maximum working height of 12 m or more. The working envelope is defined by the vertical reach combined with the horizontal clearance around the lift. Understanding these parameters is critical for planning tasks in confined spaces or elevated work areas. Manufacturers specify maximum height limits to maintain stability and operator safety.

Closed Height and Pit Installation Requirements

The closed height of scissor lifts, which is the height when fully retracted, typically ranges from 1.2 m to 2.5 m. This dimension affects transportation and storage logistics. Pit installation requires precise measurements to accommodate the lowered height while ensuring structural support and accessibility. Proper pit design must comply with load-bearing requirements and allow for smooth deployment of the lift platform.

Weight Considerations for Mobility and Stability

Scissor lift weights vary significantly based on size and construction materials, commonly between 500 kg and 4,500 kg. Weight influences mobility, with heavier units requiring more robust transport solutions. Stability is directly related to weight distribution and center of gravity; manufacturers optimize these factors to prevent tipping during operation. Compliance with ANSI and OSHA standards mandates specific weight-to-base width ratios to ensure safe movement and positioning.

Design and Safety Standards Affecting Size and Weight

ANSI/SIA and OSHA Stability and Load Regulations

The ANSI/SIA standards specify strict stability requirements for scissor lifts to prevent tipping during operation. OSHA mandates load limits based on platform size and intended use, ensuring safe operation within rated capacities. Compliance with these regulations requires manufacturers to conduct rigorous testing of structural integrity and load-bearing components. These standards directly influence the maximum allowable weight and dimensions of the equipment to maintain operator safety.

Height-to-Base Width Ratios and Movement Restrictions

Height-to-base width ratios are critical for maintaining stability during vertical extension. Scissor lifts must have a sufficiently wide base relative to their maximum height to minimize the risk of overturning. Movement restrictions are often imposed when the platform is elevated, limiting travel speed and maneuverability to reduce dynamic instability. These design constraints affect overall dimensions and operational protocols, ensuring the equipment remains stable under various working conditions.

Ground Surface and Support Requirements

Scissor lifts require firm, level ground surfaces to support their weight and maintain stability. Uneven or soft surfaces can compromise load distribution and increase the risk of accidents. Manufacturers recommend specific ground bearing pressures and surface conditions for safe operation. In some industrial settings, additional support structures or pit installations may be necessary to accommodate the lift’s footprint and weight, aligning with regulatory guidelines.

Load Distribution and Operator Positioning Guidelines

Proper load distribution on the platform is essential to avoid overloading any single point, which could lead to structural failure or instability. Operator positioning also affects the center of gravity; guidelines dictate where operators should stand or place equipment to maintain balance. Load cells and sensors are sometimes integrated to monitor distribution in real time. Adhering to these guidelines maximizes safety and performance, directly influencing the design of platform size and weight capacity.

Maintenance and Inspection Impact on Performance and Safety

Daily, Monthly, and Annual Inspection Protocols

Regular inspections are critical to ensure scissor lifts operate safely and efficiently. Daily checks focus on visual inspections of critical components such as guardrails, controls, and emergency stops. Monthly inspections include more detailed assessments of structural integrity and hydraulic systems. Annual inspections require comprehensive evaluations by certified technicians, including load testing and compliance verification with industry standards.

Hydraulic, Structural, and Electrical System Checks

Hydraulic systems must be examined for leaks, pressure consistency, and fluid levels to prevent failures. Structural inspections identify cracks, corrosion, or deformation in the lift’s frame and platform. Electrical systems undergo testing for wiring integrity, control responsiveness, and battery condition to maintain reliable operation and prevent electrical hazards.

Battery and Powertrain Maintenance for Electric Models

Electric scissor lifts require routine battery maintenance, including electrolyte level checks and charging cycle monitoring. Powertrain components such as motors and drive assemblies must be lubricated and inspected for wear. Proper maintenance extends battery life, ensures consistent power delivery, and reduces downtime in industrial environments.

Innovations in Predictive Maintenance and Diagnostics

Advances in sensor technology and IoT integration enable predictive maintenance by monitoring real-time data on lift performance and component health. Diagnostic systems can alert operators to potential failures before they occur, optimizing maintenance schedules and improving safety. These innovations reduce unexpected breakdowns and extend equipment lifespan in industrial applications.

Summary of Specifications and Best Practices for Selection and Use

Scissor lifts must be selected based on platform size, load capacity, height range, and weight to ensure operational efficiency and safety. Industry standards such as ANSI/SIA and OSHA provide critical guidelines for stability, load distribution, and movement restrictions. Adhering to these specifications minimizes risks and enhances performance in industrial environments.

Future trends emphasize integrating predictive maintenance and advanced diagnostics to improve reliability and reduce downtime. Electric powertrains require focused battery maintenance to sustain operational readiness. Regular inspections covering hydraulic, structural, and electrical systems are essential for compliance and longevity.

Practically, operators should evaluate ground surface conditions and support requirements before deployment. Proper operator positioning and load distribution are vital to maintaining balance and preventing accidents. Selecting a scissor lift involves balancing technological advancements with established safety protocols to meet evolving industrial demands effectively.