Aerial work platforms rely on clear documentation as much as on mechanical design. This article explains which publications must be kept on the aerial platform, how standards drive required manuals, and how labels and records support safe operation and legal compliance.

You will see how OSHA and ANSI/SAIA A92 rules define core documentation, which manuals must stay with the machine, and how safety decals and markings must appear and be maintained. The final section turns these rules into a practical documentation checklist that safety managers, owners, and rental fleets can apply in daily operations.

Core Standards for Aerial Work Platform Compliance

Aerial work platform compliance starts with clear rules on design, use, and documentation. Regulators linked safe operation to what is written on the machine and what is stored with it. When safety teams ask which publications must be kept on the aerial platform, they must align OSHA, ANSI/SAIA A92, and, where relevant, CE rules. This section explains how those core standards define the manuals, labels, and records that must stay with the unit or at the job site.

Key OSHA and ANSI/SAIA A92 Requirements

OSHA rules in 29 CFR 1910.67 and 1926.453 referred operators back to the manufacturer’s instructions. Those instructions sat mainly in the operator’s manual and on safety decals. Standards required that the operating manual stay on or with the aerial platform and be readable by the operator at the point of use.

ANSI/SAIA A92 standards defined design, safe use, and training duties in more detail. They required that:

- Each platform carried the correct, current operator’s manual.

- Operators read and follow that manual before use.

- Inspections and maintenance followed the manual and A92 procedures.

Inspection records for daily and frequent checks had to stay at the work site and be available for review. For safety teams optimizing for searches like which publications must be kept on the aerial platform, the minimum answer under OSHA and A92 was the manufacturer’s operator’s manual plus all required decals and markings.

Electrical Insulation and Special Use Provisions

Some aerial work platforms were rated as insulating devices for work near energized lines. For these units, standards required more than the normal operator’s manual. They also required documented test records for insulating components and systems.

When a lift was used as an insulating device, test reports for dielectric checks performed at the site had to stay at that site. Supervisors kept these with other project safety files, not always on the platform, but they had to be easy to access during audits. The operator still needed the standard publications on the aerial platform itself, including:

- Operator’s manual with electrical hazard limits and approach distances.

- Decals warning about power lines, minimum clearances, and grounding rules.

Special-use add-ons, such as fall arrest anchor points or material handling attachments, also needed instructions and limits. Those instructions either stayed in the main operator’s manual, in a separate attachment manual stored with the unit, or in site binders referenced in the job plan.

CE-Marked vs. Non-CE Platforms: Document Differences

CE-marked aerial platforms followed European rules that added extra documents to the basic OSHA and ANSI set. The core publications still mirrored the global answer to which publications must be kept on the aerial platform: an instruction manual and safety markings in the language of the users. However, CE rules also required an EC Declaration of Conformity and a technical file maintained by the manufacturer or importer.

In several EU states, periodic inspection systems demanded more site documents. Typical required items included:

- Instruction manual stored on the machine.

- Control or inspection register kept with site safety files.

- Booklet of periodic checks or first inspection report.

For non‑CE platforms, especially older imports, authorities asked for test booklets, inspection logbooks, and proof of operator and PPE training. The physical publications on the platform often looked similar, but external records differed. Engineers managing mixed fleets needed clear mapping that showed, for each serial number, which manuals must be on the machine and which certificates and inspection records must stay in site documentation sets.

Manuals That Must Be On or With the Platform

Safety rules and search queries often ask which publications must be kept on the aerial platform. Standards gave a clear answer. The operator’s manual had to be on the machine or in a storage box fixed to it. Maintenance and parts information had to be available to technicians at the site. Site procedures and inspection records had to stay with the project safety file so auditors could trace decisions and actions.

Operator’s Manual: Content and Availability

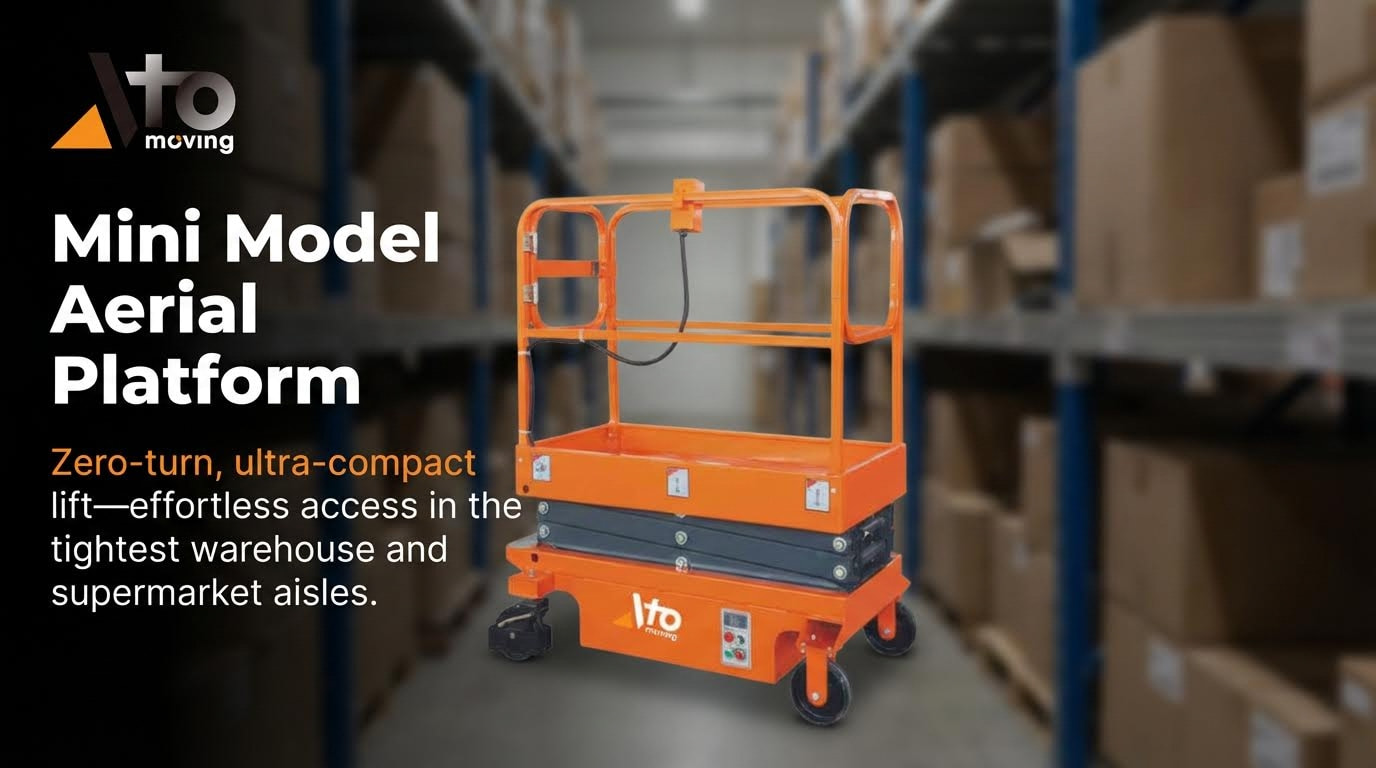

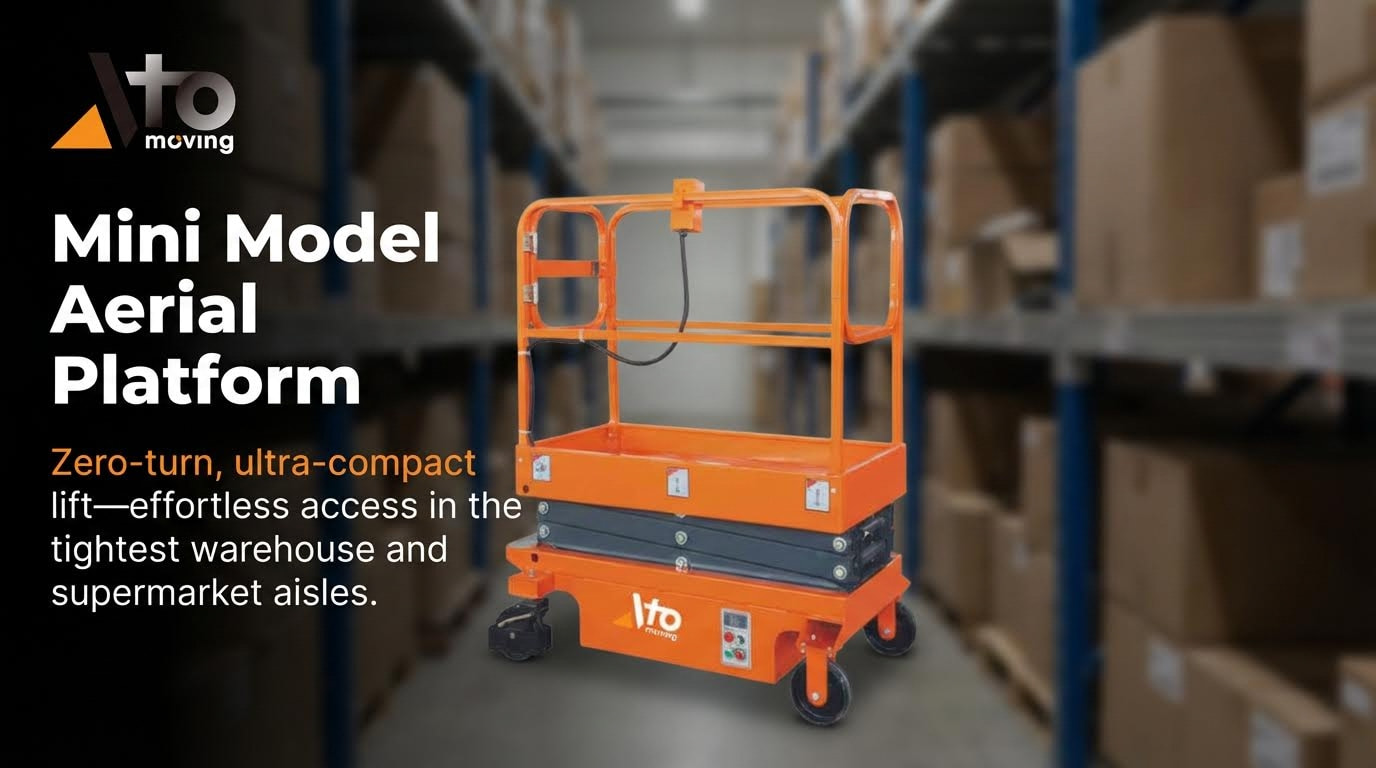

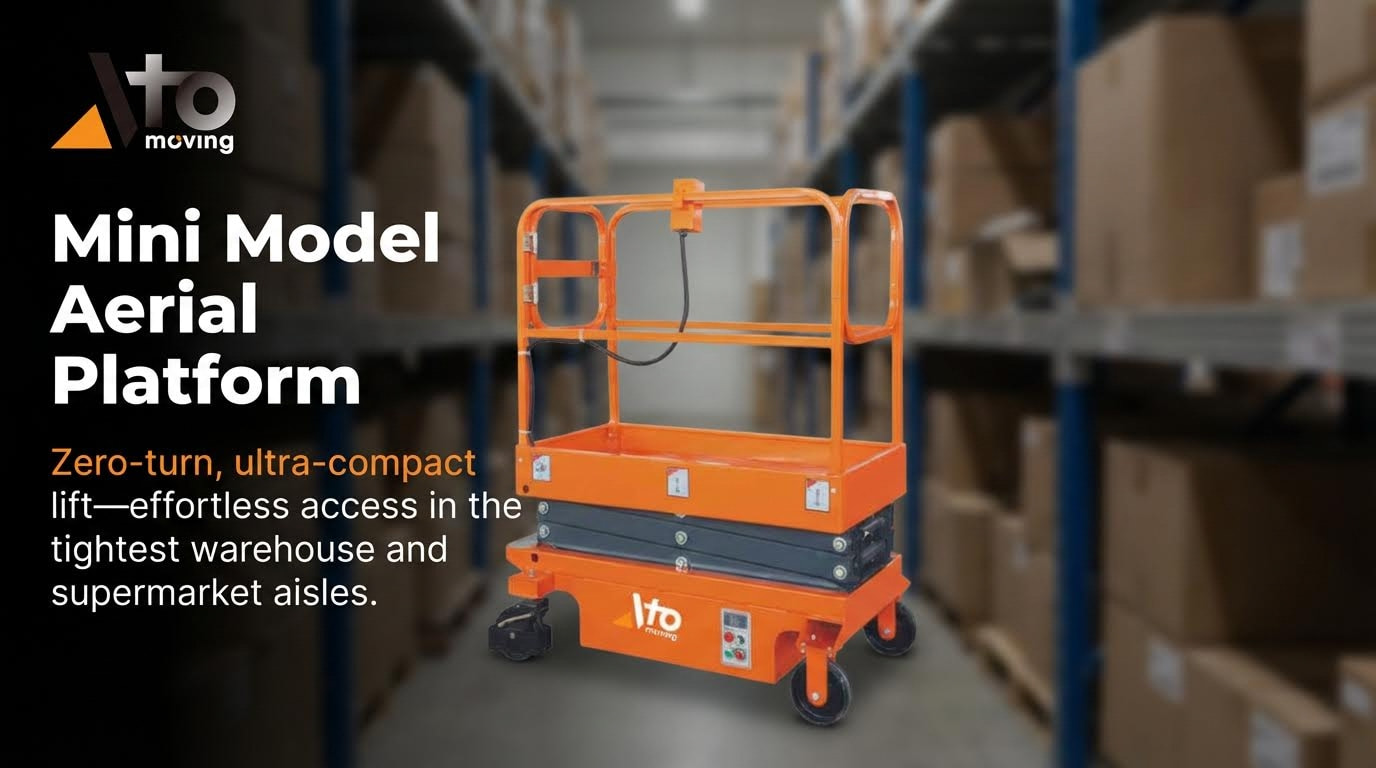

OSHA and ANSI/SAIA A92 required the manufacturer’s operating manual to be readily available on the scissor platform. This rule applied to scissor lifts, boom lifts, and vehicle‑mounted platforms. The manual had to match the exact model and configuration. Operators had to use it as the primary reference for safe use.

The operator’s manual normally included at least these topics:

- Intended use, limits, and prohibited uses

- Platform capacities, number of persons, and load distribution

- Pre‑start inspections and function tests

- Setup rules for leveling, outriggers, and stabilizers

- Operating procedures and emergency lowering methods

- Electrical, fall, and crushing hazard controls

The manual had to stay clean, legible, and protected from weather. If it was missing or unreadable, the platform should not be used until a correct replacement was installed.

Maintenance and Parts Manuals for Technicians

Maintenance and parts manuals did not always sit on the platform, but they had to be available at the work site. Technicians used them for scheduled service, fault finding, and component replacement. They also used them to confirm that replacement parts matched the original specification.

Typical maintenance manuals covered:

- Service intervals and checklists

- Hydraulic, electrical, and structural inspection points

- Torque values and adjustment procedures

- Test procedures for emergency and safety systems

Parts manuals normally listed assemblies, exploded views, and part numbers. Using the correct manuals reduced the risk of unsafe modifications and helped prove that maintenance followed the manufacturer’s instructions, as required by OSHA and A92.

Serial-Number-Specific Manuals and Updates

Modern aerial work platforms often used serial‑number‑specific manuals. Small design changes between production runs meant that one generic book no longer covered every unit. Operators and technicians had to confirm that the manual matched the serial number on the data plate.

Manufacturers sometimes issued:

- Revised pages or bulletins for safety‑critical changes

- Updated load charts after structural re‑rating

- New procedures after component redesigns

These updates had to be added to the on‑board operator’s manual and the maintenance set. A control log or revision record helped prove that the latest instructions were in use. When a platform changed owner, the new owner had to check that the manuals and updates still matched the actual configuration.

Site-Specific Procedures, JHAs, and Fall Plans

Core manuals from the manufacturer were not enough. Sites also needed local documents that reflected actual hazards and work methods. These documents did not have to be on the platform itself but had to be accessible to the crew and supervisors.

Key site publications included:

- Job Hazard Analyses (JHAs) or similar task risk assessments

- Site‑specific fall protection plans that matched anchor points and rescue methods

- Daily or shift aerial platform inspection checklists

- Work area survey forms for ground, overhead, and weather hazards

Some organizations kept these checklists and plans in a project safety folder near the work area. Others stored a copy in a weatherproof tube or box on the machine. What mattered for compliance was that workers could show, on request, which publications must be kept on the scissor platform lift and which had to stay with the site documentation. This clear split helped auditors trace how the manufacturer’s rules were applied to the actual job conditions.

Required Decals, Labels, and On-Board Markings

A key part of answering which publications must be kept on the aerial platform is understanding what information must stay on the machine itself. Decals, labels, and markings give the operator critical instructions at the point of use. They also link the physical platform to the required manuals, inspection records, and site documents stored on or near the equipment. This section explains what markings are required, how they support OSHA and ANSI/SAIA A92 compliance, and how to manage them through the life of the machine.

Safety Decals per ANSI Z535 and A92

Safety decals on aerial work platforms must follow ANSI Z535 formats and the applicable A92 series standard. These decals use defined signal words and colors to show hazard level and required actions. Typical sets include danger, warning, caution, notice, and mandatory action messages. Each message must appear in the operator’s normal field of view near the related hazard.

Standards require that safety decals remain present, legible, and correctly located. They must describe the specific hazard, the consequence, and the avoidance action in clear language. Symbols follow Z535 design rules so operators can recognize risks quickly, even in low light or noisy sites. If a decal is missing or unreadable, the platform is not in compliant condition and should be removed from service until corrected.

Key safety decal topics usually include:

- Tip-over and stability hazards on slopes and soft ground

- Crush and entrapment points near booms, scissors, and guardrails

- Electrocution risk near overhead lines and energized parts

- Fall protection use and anchor locations where required

Capacity, Operating, and Control Labels

Capacity and operating labels support safe loading and correct control use. They answer practical questions that operators ask when they decide which publications must be kept on the aerial platform for daily work. Capacity placards state rated load, number of persons, and any allowance for tools and materials. They must use consistent units, typically kilograms for load and metres for height.

Control labels identify each function at both platform and ground controls. They show direction of movement with arrows and text, and they mark emergency stop and emergency lowering devices. Clear control marking reduces operator error, especially during rescue operations. Operating instruction labels often summarize key steps from the operator’s manual, such as pre-start checks, outrigger use, and travel limits with the platform elevated.

For engineering review, labels should match the machine’s rated structural and hydraulic capacity. Any change to configuration, such as platform extensions or attachments, requires updated labels that reflect the new ratings. Mismatched labels and ratings are a frequent finding during safety audits and can invalidate risk assessments.

Inspection Tags, Checklists, and Test Records

Inspection tags and on-board records link the physical platform to its documented maintenance and test history. Regulators require that inspection records stay at the work site, and many facilities keep key documents directly on the machine. This helps close the loop between what the decal states and the actual condition of the equipment.

Typical on-board documentation includes:

- Daily or pre-use inspection checklist for the specific platform type

- Current periodic inspection tag or sticker with date and inspector ID

- Records or references for electrical insulation tests when the unit is used as an insulating device

Checklists usually cover both vehicle and lift components. Items include fluid leaks, tire condition, guardrails, emergency controls, and presence of all safety decals. Operators complete and sign these forms before use. Keeping these documents with the platform supports quick verification during audits and incident investigations.

Inspection tags must use durable materials and clear date coding. Color changes by month or year help supervisors see status from a distance. When tags show an expired date, the platform should be locked or tagged out until inspection is updated.

Decal Maintenance, Cleaning, and Replacement

Decal maintenance is part of routine scissor platform lift care. Standards require decals to remain legible for the life of the machine. Operators should check decal condition during every pre-start inspection. They must confirm that each required message is present, readable, and fixed in the correct position.

Cleaning should use mild soap and water with soft cloths. Solvent-based cleaners can soften adhesive, fade colors, and remove protective overlaminates. This damage reduces contrast and can make symbols hard to read in bright light or rain. Where pressure washing is used, operators should avoid directing the jet at label edges.

Replacement is necessary when decals peel, fade, crack, or become contaminated with paint or oil. Replacement sets should match the original manufacturer layout and follow ANSI Z535 design rules. Mixing non-standard stickers with compliant decals can confuse operators and weaken legal defensibility after incidents. Maintenance plans should include a decal map with part numbers so technicians can order and fit correct replacements without guesswork.

From a documentation control view, decal condition should align with the manuals and records kept on the aerial platform. When a manual is updated or the machine is re-rated, engineers should review all related decals and labels and replace them as needed.

Summary: Practical Documentation Checklist and Actions

Supervisors who ask which publications must be kept on the aerial platform need a simple, defensible list. Documentation must support OSHA, ANSI/SAIA A92, and any local rules, and it must match the exact machine on site. This summary turns the detailed requirements for manuals, decals, and records into clear actions for owners, renters, and site managers.

For publications that stay on the aerial platform, keep at least: the current operator’s manual for that exact serial number, quick-reference operating instructions if supplied, and emergency lowering instructions at the ground and platform controls. These documents must be readable, in the language of the operator, and protected from weather. They must match the configuration, options, and control layout actually installed on the unit.

Near the platform, but not always on it, keep maintenance and parts manuals, the control or inspection logbook, and proof of operator training. At the work site, maintain records of pre-use and periodic inspections, function tests, and any electrical insulation test reports for insulating units. Retain site-specific job hazard analyses, fall protection plans, and rescue procedures with project safety files.

Future practice will rely more on digital storage and QR codes on the machine, but regulators still expected legible hard-copy instructions and safety decals on the equipment. A practical approach is to standardize a documentation kit for every platform, verify it during each inspection, and treat any missing or outdated publication as a reason to tag the unit out of service until corrected.