Aerial work platforms and Mobile Elevating Work Platforms (MEWPs) sat at the center of strict OSHA and ANSI safety rules. This article explained what these machines were, how OSHA classified and regulated them, and how ANSI grouped and typed MEWPs for design and use. You learned which OSHA standards applied, what the OSHA standard for aerial work platforms required in practice, and how inspections, hazard controls, and operator training worked on real jobsites.

Later sections compared OSHA rules with the ANSI/SAIA A92 MEWP suite so engineers, safety managers, and fleet owners could align design limits, stability margins, and documentation. The conclusion tied together design, operation, and compliance, so teams could specify, operate, and maintain platforms that met both regulatory duties and modern best practice.

Defining Aerial Lifts And MEWPs Under OSHA And ANSI

This section explains what the OSHA standard for aerial work platforms covers in terms of equipment scope. It also links OSHA definitions to modern ANSI Mobile Elevating Work Platform (MEWP) group and type classifications. Engineers, safety managers, and rental fleets can use this mapping to align design data, manuals, and training programs.

OSHA Definitions And Equipment Classifications

OSHA used the term “aerial lift” in its core rules. It defined an aerial lift as any vehicle-mounted device used to position people. The device could be telescoping, articulating, or a combination of both. Typical OSHA categories included extendable boom platforms, articulating boom platforms, aerial ladders, vertical towers, and combination units.

When people ask what is the OSHA standard for aerial work platforms, they usually refer to 29 CFR 1910.67 and 1926.453. These standards covered design use, safe operation, and required inspections for vehicle-mounted elevating and rotating work platforms. OSHA rules focused on hazards such as falls, tip-overs, falling objects, and electric shock near overhead lines. The standards did not create a detailed group and type system, but they set minimum safety baselines that current MEWPs still had to meet or exceed.

ANSI MEWP Groups And Types (A/B, 1/2/3)

ANSI introduced the term Mobile Elevating Work Platform to give a more precise structure. The modern A92 suite grouped MEWPs by platform position and movement pattern. Group A covered machines where the platform stayed inside the tipping lines, such as scissor lifts. Group B covered machines where the platform could extend beyond the tipping lines, such as boom lifts.

Types described how the MEWP moved while elevated. Type 1 units only traveled with the platform stowed. Type 2 units used travel controls located at the chassis. Type 3 units used travel controls located at the platform. This A/B and 1/2/3 grid allowed clear classification of boom lifts, scissor lifts, and vehicle-mounted devices.

From a compliance view, OSHA standards for aerial work platforms set legal duties, while ANSI A92 design and use rules acted as best practice. During inspections, regulators often compared actual MEWP features and procedures against both OSHA text and ANSI group and type expectations. This pushed manufacturers to design machines that satisfied OSHA while aligning with MEWP stability, control, and guardrail rules in A92.20 and A92.22.

Common Platform Types And Industrial Use Cases

Aerial work platforms under OSHA and ANSI covered several core machine families. Each family matched different access heights, outreach needs, and floor conditions. Typical platform categories included:

- Boom lifts for high outreach around obstacles.

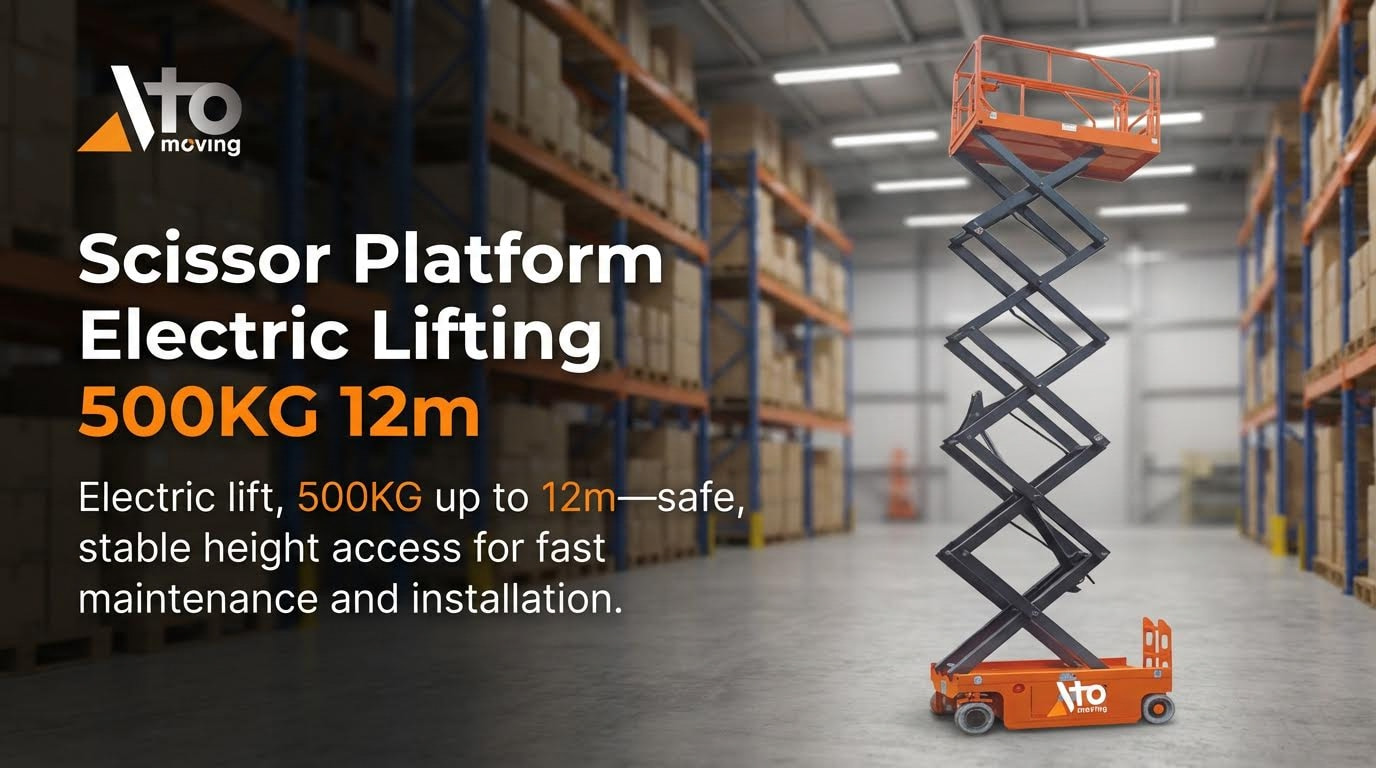

- Scissor lifts for vertical access on firm, level floors.

- Vehicle-mounted buckets for overhead line and street work.

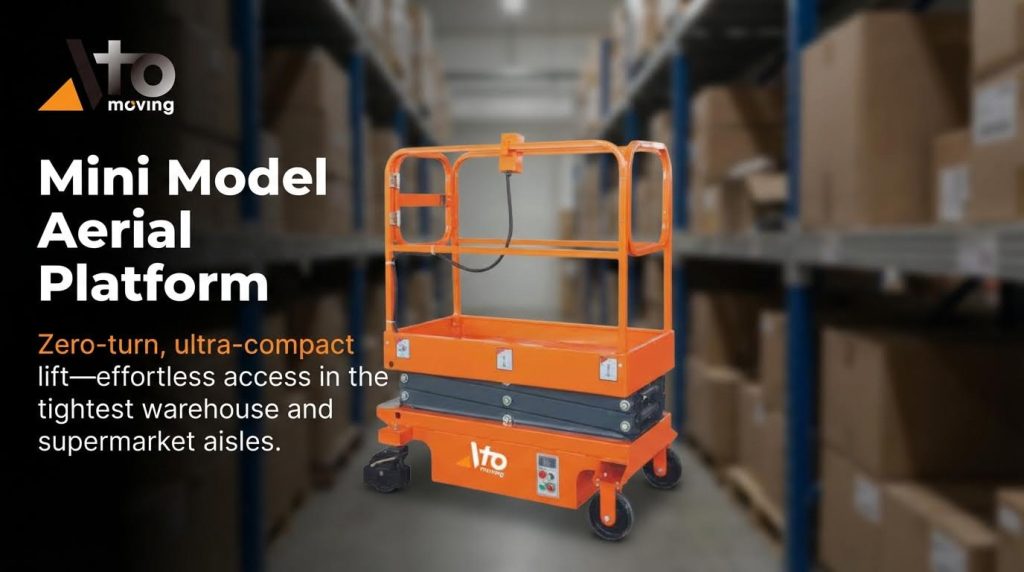

- Vertical mast lifts for tight indoor aisles.

Construction sites used boom lifts and rough-terrain scissors for steel erection, cladding, and MEP installation. Manufacturing plants used slab scissor lifts and mast lifts for equipment service over production lines. Warehouses used compact MEWPs for racking maintenance, lighting work, and sprinkler access.

Each use case tied back to what is the OSHA standard for aerial work platforms in practical terms. Employers had to select platforms with enough rated load for people, tools, and materials. They also had to respect manufacturer limits on slope, wind speed, and drive-at-height capability. ANSI MEWP groups and types helped teams choose the right machine and document that choice in safe use plans and operator training records.

Core OSHA Requirements For Aerial Work Platforms

When safety teams ask what is the osha standard for aerial work platforms, they usually mean the full set of OSHA rules that control design limits, inspection, and operation. These rules sit mainly in 29 CFR 1910.67 for general industry and 29 CFR 1926.453 for construction, plus related electrical and training provisions. Understanding how these standards link to real work tasks helps engineers set safe limits and write usable procedures. The following sections break the OSHA requirements into standards, hazard controls, inspections, and training.

Key OSHA Standards: 1910.67 And 1926.453

OSHA used two core standards to define aerial work platform duties. 29 CFR 1910.67 covered vehicle‑mounted elevating and rotating work platforms in general industry. 29 CFR 1926.453 covered aerial lifts used in construction work. Both standards tied back to the same basic question from safety managers and engineers: what is the osha standard for aerial work platforms in this specific job.

These standards required:

- Use of equipment within manufacturer ratings and design limits.

- Daily functional checks of controls and safety devices.

- Fall protection and guardrails on elevated platforms.

- Safe distances from energized electrical lines.

OSHA also linked aerial platform use to general electrical rules in 1910.333, accident prevention in 1926.20, and safety training in 1926.21. Together, these clauses created a complete compliance framework for design review, job planning, and field operation.

Hazard Controls: Falls, Tip-Overs, And Electrocution

OSHA treated falls, tip‑overs, and electrocution as the main loss drivers for aerial work platforms. The standards required guardrail systems on platforms and banned climbing or standing on mid‑rails or using ladders or planks on the deck. Operators had to keep access gates closed and stand on the platform floor at all times.

To control tip‑over risk, OSHA required:

- Operation only on stable, level support surfaces.

- Use of outriggers, pads, and wheel chocks as specified.

- No travel with the platform elevated unless the manufacturer allowed it.

- Respect of rated load, including tools and materials.

Electrocution controls focused on approach distances and line status. Operators had to treat all overhead lines as energized, keep at least 3 metres separation, and use de‑energizing or insulating barriers when work needed closer access. Drilling or modifying insulated buckets was prohibited because it reduced dielectric protection.

Pre-Start, Work Area, And Shift Inspections

OSHA required structured inspections before and during each shift. A pre‑start inspection checked both vehicle and lift components. Typical items included fluid levels, leaks, tires, steering, brakes, lights, and alarms on the chassis. On the platform side, operators checked operating and emergency controls, guardrails, placards, hydraulic hoses, wiring, and any insulating parts.

Work area inspections focused on environmental and layout hazards. Engineers and supervisors had to look for drop‑offs, holes, soft ground, slopes, overhead obstructions, power lines, high winds, ice, and bystanders. If conditions changed, the risk review had to be repeated.

OSHA required that defective aerial lifts be removed from service until repaired and tested. This rule applied to structural cracks, hydraulic leaks, malfunctioning controls, or damaged guardrails. For high‑reliability sites, many companies extended OSHA’s minimums with documented checklists, color‑coded tags, and periodic third‑party inspections.

Operator Training, Retraining, And Documentation

OSHA required that only trained and authorized workers operate aerial work platforms. Training needed both theory and hands‑on parts. Core topics included hazard recognition, safe operation within rated loads, fall protection methods, electrical approach limits, and daily inspection steps.

Retraining was mandatory when incidents occurred, unsafe operation was seen, workplace conditions changed, or a different type of aerial platform was introduced. This linked directly back to the compliance question what is the osha standard for aerial work platforms, because inspectors often asked to see how retraining triggers were defined.

From an engineering management view, solid documentation was essential. Employers had to keep records that showed who was trained, on which equipment class, and when. Strong programs also tied training records to specific machine IDs, inspection logs, and written procedures, so that design assumptions, safe‑use limits, and operator behavior stayed aligned over the life of the equipment.

ANSI/SAIA A92 Standards And Engineering Implications

ANSI/SAIA A92 standards complemented OSHA rules that answered the question “what is the OSHA standard for aerial work platforms.” OSHA set minimum legal duties, while A92 standards defined modern engineering and safe use practice for MEWPs. Design engineers, owners, and safety managers used both frameworks together. This section explained how the A92 MEWP suite reshaped design, stability, and field operation.

Transition From Legacy A92.3, A92.5, A92.6 To MEWP Suite

The legacy A92.3, A92.5, and A92.6 standards focused on product families such as boom lifts and self‑propelled elevating platforms. They used separate rule sets for each machine style, which created overlap and gaps. The MEWP suite replaced these with a unified structure based on machine behavior and use, not product marketing labels.

ANSI/SAIA administratively withdrew A92.3, A92.5, and A92.6 in 2020. The new suite centered on A92.20 (design), A92.22 (safe use), and A92.24 (training). This shift supported OSHA obligations under 29 CFR 1910.67 and 1926.453 by giving clearer design and operating benchmarks.

For engineering teams, the change meant one consolidated rule base for structural checks, stability, and controls. For employers, it aligned training, inspections, and safe use planning across all MEWP types. This reduced confusion when answering internal questions about what is the OSHA standard for aerial work platforms and how ANSI guidance supported it.

A92.20 Design, Stability, And Test Requirements

A92.20 set performance requirements for MEWP design and testing. It addressed structural strength, stability margins, control layout, and safety devices. Manufacturers had to prove compliance before a unit entered service.

Key engineering themes included:

- Structural design using defined load cases and safety factors.

- Stability criteria for static, dynamic, and wind loading.

- Guardrail, gate, and toe‑board geometry for fall prevention.

- Redundant or monitored safety functions for critical systems.

Test requirements covered tilt, overload, function, and emergency lowering. Typical programs verified platform capacity with tools and personnel, plus dynamic effects from braking and slewing. Stability tests checked resistance to tip‑over on rated slopes and with rated wind speeds.

These provisions supported OSHA’s focus on preventing falls, tip‑overs, and electrocution. When employers asked what is the OSHA standard for aerial work platforms, engineers could show that A92.20 design compliance underpinned safe operation under OSHA rules. The result was better alignment between equipment capability labels and real‑world conditions on jobsites.

A92.22 Safe Use Planning And Worksite Risk Assessment

A92.22 defined how users planned safe MEWP work, beyond basic OSHA compliance. It required a documented safe use plan and a structured risk assessment for each application. This tied directly to OSHA expectations on hazard identification and control.

Typical planning steps included:

- Selecting the correct MEWP group and type for the task.

- Surveying the work area for drop‑offs, slopes, power lines, and overhead obstructions.

- Defining control measures such as exclusion zones, traffic control, and wind limits.

- Assigning roles for supervision, operation, and ground support.

Risk assessment considered fall, tip‑over, entrapment, and electrical hazards. Controls could include platform load limits, use of outriggers, and minimum approach distances to energized lines. The standard also emphasized pre‑start and frequent inspections that matched OSHA’s inspection focus.

By following A92.22, employers could show that they went beyond asking what is the OSHA standard for aerial work platforms. They could demonstrate a repeatable process that integrated ANSI best practice with OSHA’s general duty to provide a safe workplace.

A92.24 Training, Familiarization, And Rescue Planning

A92.24 addressed who needed MEWP training, what topics to cover, and how to document results. It complemented OSHA requirements for operator training and retraining. The standard split responsibilities between operators, supervisors, occupants, and owners.

Training content typically covered:

- MEWP classifications by group and type.

- Hazards such as falls, electrocution, and entrapment.

- Manufacturer operating limits, including load and wind ratings.

- Inspection steps and shutdown criteria for unsafe conditions.

A92.24 also required familiarization with the specific machine model before use. This included control locations, emergency lowering, and any unique features. Rescue planning formed a core part of the standard. It described self‑rescue, assisted rescue from the ground, and external technical rescue by emergency services.

From a compliance view, this framework helped employers answer what is the OSHA standard for aerial work platforms in practical terms. OSHA set the duty to train and protect workers. A92.24 supplied a detailed blueprint for course content, recordkeeping, and rescue readiness that safety teams could implement and audit.

Summary: Aligning Design, Operation, And Compliance

Facilities that asked what is the osha standard for aerial work platforms needed a joined-up approach. Compliance depended on linking OSHA rules, ANSI guidance, and engineering limits for each machine. This section pulls those elements together so design teams, safety staff, and operations worked from one playbook.

From a regulatory view, the core OSHA standard for aerial work platforms was 29 CFR 1910.67 and 29 CFR 1926.453. These rules defined aerial lifts, set safe-use basics, and tied requirements to electrical, fall, and struck-by hazards. ANSI/SAIA A92.20, A92.22, and A92.24 then added performance-based design, safe-use planning, and structured training models. Aligning both sets of documents helped organizations defend their risk controls during audits and incident reviews.

Engineering teams had to design or select MEWPs that met A92.20 stability, load rating, and test criteria. Safety teams then built procedures around OSHA duties for inspections, training, and work-practice controls. Operations managers closed the loop with site-specific rules on ground conditions, power-line clearance, and rescue plans.

Looking forward, aerial work platform compliance moved toward more data-driven inspections, digital training records, and telematics-based monitoring of overloads and unsafe motion. The fundamentals stayed the same. Clear answers to what is the osha standard for aerial work platforms still started with 1910.67 and 1926.453, then integrated ANSI as the detailed roadmap for design, operation, and continuous improvement.