Facilities that ask what are elevating work platforms usually need safe, repeatable access above floor level. This article explains how scissor, boom, and vertical mast lifts differ in structure, motion, and power systems across the full outline of core design, application engineering, safety, and maintenance.

You will see how engineers match platform type to indoor or outdoor jobs, rough-terrain conditions, and reach around obstructions. The middle sections compare load cases, duty cycles, rental economics, and lifecycle budgets, then link these choices to OSHA and ANSI/SAIA rules, fall protection, and inspection programs.

The final part converts these technical points into practical selection guidelines that maintenance, construction, and facility teams can use. By the end, you will have a clear framework to choose between scissor, boom, and mast platforms for each work-at-height task.

Core Design Differences In Work Platforms

Engineers asking what are elevating work platforms need clear design comparisons. Core architecture, lift mechanics, platform geometry, and powertrain choice define where each machine works best. This section explains how scissor, boom, and vertical mast lifts differ structurally and functionally. It links those differences to height, reach, capacity, and energy use so selection decisions stay evidence based.

Scissor, Boom, And Vertical Mast Architectures

Scissor lifts use crossed X-brace arms that extend and contract in a vertical plane. The structure guides the platform straight up and down on a fixed footprint. This geometry creates a wide base and high stiffness, which suits higher loads and larger platforms. Typical industrial scissor platforms range from about 3–6 square metres.

Boom lifts use one or more arms with telescopic or articulating joints. The arm pins transfer bending and torsion back to the chassis through a turntable. This layout trades some inherent stiffness for reach and rotation. Platform areas stay smaller, often near 1.5–2.5 square metres, to control moment loads.

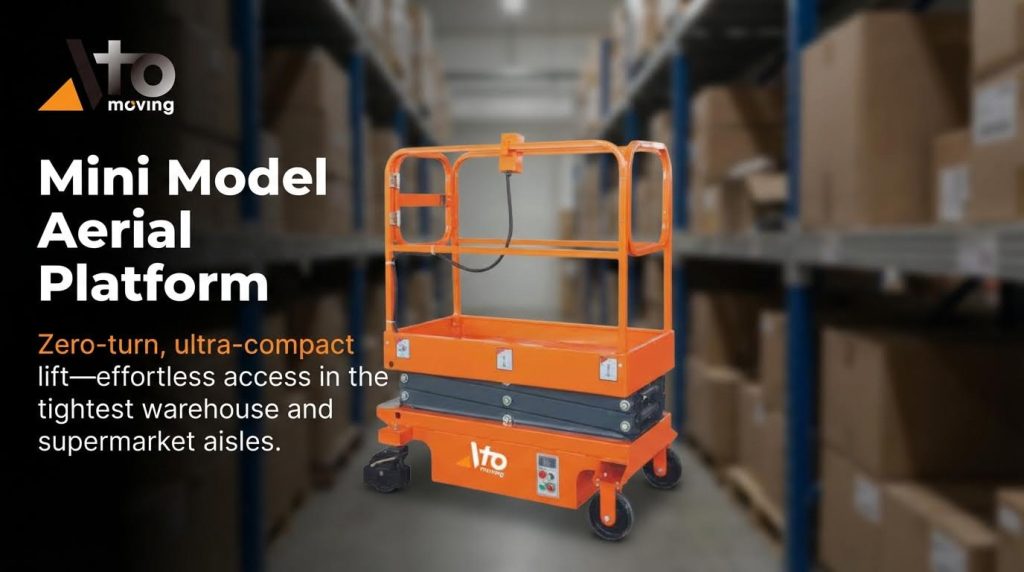

Vertical mast lifts use a compact telescoping mast or rail column. The mast guides a small platform in a near-vertical path with minimal sway. These units fit tight aisles and low floor load limits, such as retail or light maintenance. Their architecture favours low weight and small footprint over high capacity.

Vertical Lift Mechanics Versus Articulated Reach

Scissor and mast lifts provide pure vertical motion. The centre of gravity stays close to the chassis centreline. This reduces overturning moments and simplifies stability calculations. Operators position the base directly under the work area before elevating.

Boom lifts add horizontal reach through telescoping sections and articulated joints. The platform can move up, out, and over obstacles without repositioning the chassis. This requires careful control of dynamic loads, especially when slewing or telescoping at height. Manufacturers limit envelope zones and speeds to keep the stability margin.

Engineering tradeoffs appear in duty planning. Vertical lifts suit repetitive up‑down cycles with short travel paths. Articulated reach suits tasks with frequent lateral repositioning or work over voids, such as streets or plant equipment. Selection should match the lift path to the site geometry and obstruction map.

Platform Size, Capacity, And Stability Tradeoffs

Platform area, rated load, and base width link directly through stability physics. A wider base and shorter outreach allow higher capacities on scissor lifts. Typical industrial scissors handle roughly 450–1,100 kilograms, depending on height and platform size. Load charts often reduce allowable mass as height increases by 15–25%.

Boom lifts carry smaller loads because the arm creates large overturning moments. Typical capacities fall near 225–450 kilograms. The platform area stays compact to keep loads close to the arm centreline. Operators must respect both total load and side‑load limits to avoid structural overstress.

Vertical mast lifts usually support lighter loads again, often one worker with tools. Their narrow chassis fits tight spaces but reduces lateral stability margin. Manufacturers control this with outriggers, interlocks, and strict maximum height ratings. Engineers should compare:

| Lift type | Typical platform area | Typical capacity | Best use |

|---|---|---|---|

| Scissor | 3–6 m² | High | Wide, heavy work zones |

| Boom | 1.5–2.5 m² | Medium | Reach over obstacles |

| Vertical mast | <2 m² | Low–medium | Tight indoor spaces |

Powertrain Options: Electric, Diesel, And Hybrid

Powertrain choice controls emissions, noise, and duty capability. Electric drives use battery packs and electric traction plus hydraulic pumps. They suit indoor or low‑ventilation sites because they produce zero point‑of‑use exhaust. Noise levels often stay below about 65 decibels, which helps in warehouses and public buildings.

Diesel drives supply high continuous power for outdoor and rough‑terrain work. They handle long travel distances, slopes, and high hydraulic demand. However, they produce exhaust and higher noise, so they fit open or well‑ventilated areas. Rough‑terrain boom lifts with diesel engines often pair with large tyres and oscillating axles.

Hybrid systems combine batteries with combustion engines, often using intelligent control. The engine charges batteries or supports peak loads, while electric mode covers quiet or emission‑sensitive periods. Hybrids help fleets meet stricter air‑quality rules and fuel‑cost targets. Engineers should compare duty cycle length, charging access, and local emission rules before choosing a powertrain for any elevating work platform.

Application Engineering And Selection Criteria

Engineers who ask what are elevating work platforms focus on matching lift type to task, site, and budget. Application engineering links platform architecture, powertrain, and safety limits to real job demands. Good selection avoids oversizing equipment while still meeting reach, load, and utilization targets. This section explains how to choose between scissor, boom, and mast lifts for specific projects.

Indoor Versus Outdoor And Rough-Terrain Use

Indoor projects usually favor electric scissor or vertical mast lifts with compact footprints and low noise. Typical indoor scissor lifts operate below 65 dB and produce no exhaust, which suits warehouses and retail spaces. Non‑marking tires protect finished floors, while tight turning radii support narrow aisles. Engineers still verify floor loading because high-capacity platforms can exceed slab limits.

Outdoor work often needs boom lifts with higher ground clearance and wider wheel tracks. Rough‑terrain versions use aggressive tires, oscillating axles, and outriggers for stability on uneven ground. Some models operated safely on slopes up to about 45°, but only within manufacturer charts. Agricultural and construction studies showed that rough‑terrain capability reduced outdoor operating costs by around 20% due to fewer relocations and setup changes.

Selection usually follows a simple path: indoor, flat, repeat access favors electric scissors or masts; outdoor, variable terrain, and dispersed work points favor booms. Mixed sites, such as logistics hubs with yard and dock work, may justify a split fleet. In those cases, engineers map duty cycles by zone before sizing each platform type.

Height, Reach, And Access Around Obstructions

Scissor lifts answer vertical access needs when the work area sits directly above the base. Typical units offered working heights from about 6 m to 15 m. Platform areas of 3–6 m² gave space for two workers plus tools. However, once the task needed offset reach, scissor platforms became inefficient or unusable.

Boom lifts solved this by adding horizontal outreach. Telescopic booms extended straight for maximum reach, while articulating booms added joints to move up and over obstacles. Some modern booms reached over 30 m in height and delivered 150% more horizontal reach than equivalent scissors. Articulating models also enabled 360° slewing, which helped when working around pipe racks, conveyors, or façade features.

Vertical mast lifts filled a niche for moderate heights in tight spaces. They offered better reach than a scissor with smaller platforms, which suited facility maintenance in congested plants. During selection, engineers typically plotted required working envelope: minimum and maximum height, horizontal offset, and rotation needs. The platform chosen was the smallest model that fully enclosed this envelope with safety margin for positioning error.

Load Cases, Duty Cycles, And Utilization Targets

Platform load capacity must cover personnel, tools, and materials with allowance for change orders. Scissor lifts commonly supported about 450–1,100 kg, while booms often carried 225–450 kg. Heavier loads usually reduced available height by roughly 15–25%, which engineers accounted for using manufacturer load charts. Concentrated loads like compressors or glass packs also needed local deck reinforcement checks.

Duty cycle shaped powertrain and component sizing. Short, intermittent indoor tasks fit smaller electric scissors with modest battery packs. Continuous multi‑shift work, such as order‑picking or large‑area painting, benefited from higher‑capacity batteries, fast chargers, or hybrid drives. For boom lifts, service schedules often followed hour‑based intervals at 50, 250, 500, and 1,000 hours, so projected usage directly affected maintenance planning.

Utilization targets guided own‑versus‑rent decisions. Fleets with year‑round work at moderate heights could standardize on a few core models to maximize uptime and simplify spares. Contractors with spiky demand, or with occasional extreme height jobs, usually relied on rental. Engineers often created a matrix that linked job types, crew sizes, and tool sets to platform class and rated capacity.

Cost, Rental Economics, And Lifecycle Budgeting

Cost analysis for elevating work platforms compares daily rental, long‑term hire, and ownership. Typical daily rental rates for scissor lifts ranged around USD 175–300, while boom lifts sat higher at about USD 400–650. Weekly rates often discounted daily prices by 15–25%, which made sense for projects longer than four days. Engineers also added freight, fuel, and operator training costs to get a realistic job budget.

Ownership economics depended on annual operating days. For users who ran lifts 50 or more days per year, purchase could beat rental after several seasons. A mid‑range scissor lift around USD 60,000 could reach payback in roughly three to four years if weekly savings exceeded USD 300. However, this only held when maintenance programs were disciplined and downtime stayed low.

Maintenance formed a large share of lifecycle cost. Studies reported annual maintenance at about 18–22% of purchase price for scissors and 25–30% for booms, reflecting more complex hydraulics and controls. Unplanned failures, especially on booms, could reach five‑figure repair and delay costs. Robust inspection routines, stocked critical spares, and digital maintenance planning tools reduced this risk and protected project margins.

When teams asked what are elevating work platforms from a budget view, the answer combined direct costs with productivity gains. Properly matched platforms cut setup time, reduced rework, and improved safety statistics. Lifecycle budgeting therefore weighed not only rental or finance charges but also schedule reliability and compliance exposure.

Safety, Standards, And Maintenance Strategies

Safety engineering for elevating work platforms links design limits, operator behavior, and regulatory rules. When teams ask what are elevating work platforms, they also need to understand how standards control real job-site risks. This section explains how OSHA and ANSI/SAIA rules apply, how fall protection and wind affect tip-over margins, and how disciplined maintenance and digital tools keep platforms safe and available. The focus stays on scissor, boom, and mast lifts used as mobile elevating work platforms.

OSHA And ANSI/SAIA Compliance For MEWPs

OSHA treated scissor lifts as mobile scaffolds and aerial platforms. Relevant rules included 29 CFR 1910.27, 1910.28, 1910.29, and 1926.451 for construction. These rules required guardrails, fall protection, safe access, and training for elevated work.

ANSI/SAIA A92 standards defined design, inspection, and operator duties for MEWPs. Earlier documents such as A92.3 and A92.6 covered self-propelled elevating work platforms. Newer consolidated standards, including A92.20, required daily inspections, rated load markings, and tilt or overload protection.

From an engineering view, compliance meant converting rules into checklists and limits:

- Guardrail height and load rating on all platforms.

- Defined maximum slope before travel interlocks engaged.

- Mandatory pre-use inspections documented for each shift.

Facilities that treated compliance as a design input, not paperwork, saw fewer incidents and less unplanned downtime.

Fall Protection, Wind Limits, And Tip-Over Risks

Scissor lifts relied on full guardrail systems as primary fall protection. Workers had to stay on the deck and avoid climbing rails or using ladders on the platform. Boom lifts and many mast lifts required full-body harnesses with lanyards anchored to approved points.

Wind was a major driver of tip-over risk. Typical rated outdoor wind limits ranged around 7–12.5 m/s, depending on model and platform type. Some scissor lifts carried lower limits than booms because of larger exposed side area. Exceeding the published wind speed, or adding large sheet materials on the deck, reduced stability margins sharply.

Engineers and supervisors controlled tip-over risk by:

- Keeping within rated load and side-load limits.

- Blocking off soft ground and slopes beyond the machine rating.

- Enforcing no-travel rules when elevated above the manufacturer’s limit.

Documented rescue plans and clear exclusion zones around the machine further reduced secondary injury risk during incidents.

Preventive Maintenance And Inspection Programs

Effective maintenance programs started with three layers of inspection. Operators performed pre-use checks of controls, guardrails, tires, and visible leaks. Technicians handled scheduled services at fixed hour intervals. Third-party or in-house engineers completed annual detailed inspections for structural and safety systems.

Typical preventive tasks included:

- Lubrication of scissor pivots, boom pins, and mast slides.

- Hydraulic system checks for leaks, hose wear, and fluid condition.

- Battery water level, charge behavior, and cable corrosion for electric units.

- Brake, steering, and emergency lowering system tests.

Neglect of simple items, such as hydraulic oil level or filter changes, often led to high-cost failures and long downtime. Contractors that tracked running hours and duty cycles usually aligned service intervals better with real use, which extended component life and kept platforms inside their original design envelope.

Digital Tools, CMMS, And Predictive Technologies

Digital tools changed how teams managed what are elevating work platforms in mixed fleets. Computerized maintenance management systems (CMMS) stored inspection records, scheduled services, and tracked regulatory certificates. Mobile apps allowed technicians to close work orders and attach photos from the job site.

More advanced fleets added telematics modules. These devices reported operating hours, fault codes, and sometimes tilt or overload events. Managers used this data to spot misuse patterns, such as frequent overload alarms or repeated low-battery events, and then adjust training or job planning.

Predictive approaches remained simple but effective. Trend analysis on oil contamination, battery health, or recurring error codes helped schedule component replacements before failure. This reduced emergency rentals and avoided project delays caused by sudden lift outages.

When digital systems aligned with OSHA and ANSI/SAIA record-keeping needs, they cut audit time and improved proof of compliance. The most successful users combined software with clear responsibilities, operator feedback loops, and periodic program reviews to keep safety performance improving over time.

Summary And Practical Selection Guidelines

Elevating work platforms answer a core question for engineers and safety teams: what are elevating work platforms and how should they be selected. They are powered access machines that lift people, tools, and materials to height with controlled motion and defined safety systems. Scissor, boom, and mast lifts all solve this task, but with very different reach, stability, and cost profiles. A structured selection method reduces risk, improves productivity, and keeps lifecycle cost predictable.

From a technical view, scissor lifts suit vertical access on firm, level floors where platform area and capacity matter more than outreach. Boom lifts fit tasks that need horizontal reach around obstacles, variable terrain, or heights above typical warehouse roofs. Vertical mast lifts plug the gap for tight indoor aisles and light loads where low weight and compact size matter. Matching platform type to duty cycle, surface condition, and required working envelope prevents,

Frequently Asked Questions

What are elevating work platforms?

Elevating work platforms (EWPs) are devices used to lift and position workers above ground level. They are also known as aerial work platforms or lifts. Common types include scissor lifts, boom lifts, and aerial devices. These platforms can be vehicle-mounted or self-propelled and may feature telescoping, articulating, or both types of movement. EWP Guide.

What are the two basic types of elevating work platforms?

The two basic types of elevating work platforms are scissor lifts and boom lifts. Scissor lifts provide vertical elevation and are ideal for reaching heights directly above the base. Boom lifts, on the other hand, offer greater flexibility with extendable arms that can reach over obstacles. Safe Work Australia.

Is an elevator a raised platform?

No, an elevator is not typically considered a raised platform in the context of material handling or construction. Elevators are enclosed systems designed to transport people or goods between levels in a building. In contrast, raised platforms like EWPs are open and designed specifically for lifting workers and equipment at job sites. Elevator Basics.