Aerial work platforms (AWPs) are vital tools in construction, maintenance, and industrial operations. Ensuring their safe use and reliability requires a thorough understanding of safety principles and inspection protocols. This article outlines key safety practices, inspection schedules, and maintenance techniques for engineers responsible for AWP management.

Engineers must integrate regulatory compliance with practical risk mitigation strategies to protect operators and equipment. The following sections detail types of AWPs, inspection procedures, hydraulic and mechanical maintenance, and a summary of essential safety management practices.

Key Safety Principles for Aerial Work Platforms

Types of Aerial Work Platforms and Their Applications

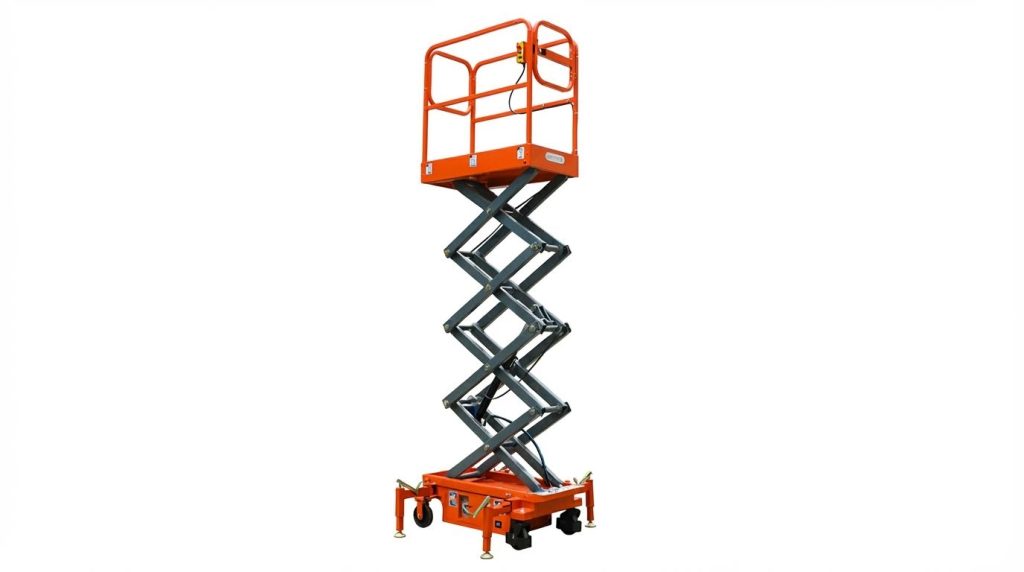

Aerial work platforms (AWPs) come in various types, including scissor lifts, boom lifts, and vertical mast lifts. Each type serves specific applications based on reach height, load capacity, and maneuverability. Scissor lifts provide vertical elevation and are ideal for indoor maintenance and construction tasks. Boom lifts offer extended horizontal reach, suitable for outdoor work on uneven terrain or hard-to-access areas. Choosing the correct AWP type ensures operational efficiency and safety compliance.

Critical Safety Standards and Regulatory Compliance

AWPs must comply with standards such as ANSI A92 and OSHA regulations to ensure operator safety and equipment reliability. These standards specify design criteria, load limits, stability requirements, and safety features like guardrails and emergency controls. Regulatory compliance mandates regular inspections and adherence to manufacturer guidelines. Engineers must verify that all AWPs used on-site meet these standards to minimize liability and enhance workplace safety.

Common Hazards and Risk Mitigation Strategies

Common hazards include falls from height, tip-overs, electrical contact, and equipment malfunctions. Risk mitigation involves implementing guardrails, fall arrest systems, and ensuring proper ground conditions to prevent instability. Operators should avoid overhead obstructions and maintain safe distances from power lines. Regular equipment inspections and hazard assessments before use reduce accident potential. Engineering controls and administrative procedures together create a safer operating environment.

Operator Training and Fall Protection Systems

Proper operator training is critical for safe AWP use, covering equipment operation, hazard recognition, and emergency procedures. Training programs must comply with OSHA requirements and include hands-on instruction and evaluation. Fall protection systems such as harnesses and lanyards are mandatory when working at heights. These systems must be inspected regularly and used in conjunction with secure anchor points. Continuous refresher training ensures operators maintain competency and adapt to evolving safety standards.

Inspection Protocols and Maintenance Scheduling

Inspection protocols and maintenance scheduling are critical to ensuring the safe and reliable operation of aerial work platforms (AWPs). These procedures help identify potential failures early and maintain compliance with safety regulations. A structured approach to inspections supports longevity and operational readiness of the equipment.

Pre-Start Inspections: Scope and Operator Responsibilities

Pre-start inspections are mandatory before each use of an aerial work platform. Operators must verify the condition of key components such as guardrails, controls, emergency stop functions, and platform stability. Visual checks for hydraulic leaks, tire condition, and structural integrity are essential. Operators are responsible for documenting any deficiencies and reporting them immediately to maintenance personnel to prevent unsafe use.

Routine Inspections: Quarterly and Annual Requirements

Routine inspections occur quarterly and annually to provide a more thorough assessment beyond pre-start checks. Quarterly inspections focus on wear and tear of mechanical parts, hydraulic systems, and electrical components. Annual inspections include detailed evaluations of load-bearing structures and safety devices. These inspections must follow manufacturer guidelines and applicable standards such as ANSI A92 or EN 280 to ensure regulatory compliance.

Periodic and Major Inspections: Procedures and Intervals

Periodic inspections, typically conducted every 12 months or after a certain number of operating hours, involve comprehensive testing of all mechanical, hydraulic, and electrical systems. Major inspections may require disassembly of critical components for in-depth examination and replacement of worn parts. These inspections are performed by qualified technicians and must be recorded meticulously to maintain traceability and certification.

Documentation and Reporting for Compliance

Accurate documentation and timely reporting are vital for audit readiness and compliance with occupational safety regulations. Inspection records should include dates, findings, corrective actions, and inspector credentials. Digital record-keeping systems enhance accessibility and data integrity. Proper documentation supports continuous improvement in maintenance practices and demonstrates adherence to legal requirements.

Hydraulic and Mechanical System Maintenance

Hydraulic Fluid Management and Temperature Control

Hydraulic fluid quality directly affects the performance and longevity of aerial work platforms. Maintaining appropriate fluid levels and using manufacturer-recommended hydraulic oils is essential. Temperature control is critical; operating outside the recommended temperature range can degrade fluid properties, leading to reduced system efficiency and increased wear. Implementing cooling systems or heat exchangers helps maintain optimal fluid temperature during extended use.

Inspection and Servicing of Hydraulic Hoses and Valves

Regular inspection of hydraulic hoses and valves is vital to prevent leaks and failures. Visual checks should identify cracks, abrasions, and bulges, while pressure testing ensures integrity under operational loads. Servicing includes timely replacement of worn hoses and cleaning or recalibrating valves to maintain precise control. Using hoses with appropriate pressure ratings and protective coverings reduces damage risk in harsh environments.

Lubrication Practices for Moving Components

Proper lubrication minimizes friction and wear on mechanical parts such as bearings, joints, and pivot points. Selecting the correct lubricant type and grade according to manufacturer specifications ensures effective protection. Lubrication intervals must align with operating hours and environmental conditions. Automated lubrication systems can improve consistency and reduce maintenance downtime, especially in heavy-use scenarios.

Electrical System Checks and Environmental Protection

Electrical components require routine inspection to detect corrosion, loose connections, or insulation damage. Ensuring proper sealing and environmental protection prevents moisture ingress and contamination. Testing battery health, wiring harnesses, and control systems contributes to reliable platform operation. Compliance with electrical safety standards reduces risks of short circuits and component failures in various working conditions.

Summary of Inspection and Safety Management Essentials

Effective inspection and safety management are critical to ensuring the reliable operation of aerial work platforms (AWPs). Regular inspections, including pre-start, routine, and major checks, help identify wear, damage, or malfunction early. This proactive approach minimizes downtime and prevents accidents by maintaining compliance with safety standards such as ANSI and OSHA regulations.

Maintenance of hydraulic and mechanical systems is essential. Proper hydraulic fluid management, hose inspections, lubrication, and electrical system checks protect AWPs from failures caused by environmental factors and operational stresses. Documentation of inspections and repairs is mandatory for traceability and regulatory compliance.

Industry trends emphasize integrating digital monitoring and predictive maintenance technologies to enhance safety and efficiency. Engineers must balance adopting new technologies with proven inspection protocols to optimize platform reliability. Practical implementation requires comprehensive operator training and adherence to fall protection systems, ensuring user safety alongside equipment integrity.

In summary, a structured inspection schedule combined with thorough mechanical upkeep and operator education forms the foundation of AWP safety management. This balanced approach supports evolving technological advances while maintaining stringent safety and operational standards in the field.