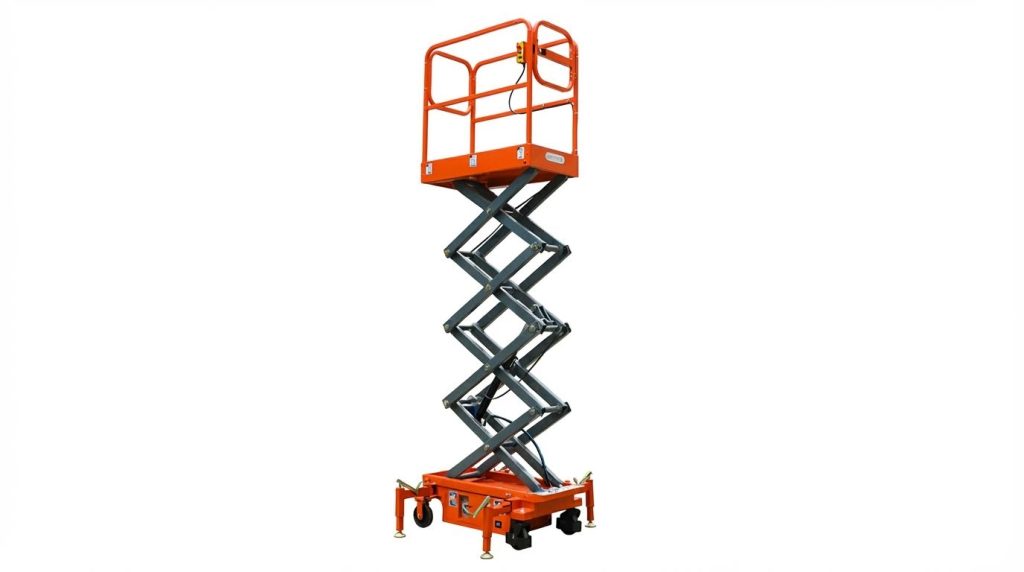

Aerial work platforms and mobile elevating work platforms played a central role in high-access tasks across construction, maintenance, and industrial operations. Their safety performance depended heavily on disciplined inspections, preventive maintenance, and operator competence. This article outlined core safety risks and regulatory requirements, structured inspection regimes and checklists, and maintenance engineering practices that supported reliability and compliance. It concluded with a concise synthesis of key controls and engineering takeaways to guide owners, fleet managers, and safety professionals in establishing robust MEWP safety programs.

Core Safety Risks And Regulatory Requirements

Core risks on aerial work platforms related to falls, tip-overs, and electrocution required structured controls. Regulators worldwide mandated systematic inspections, operator training, and worksite risk assessments. Engineering controls, procedural discipline, and competent maintenance together reduced incident rates. This section outlined the regulatory framework and the dominant accident mechanisms engineers needed to address.

OSHA And Global Standards For MEWP Safety

OSHA standards 29 CFR 1910.67 and 1926.453 defined baseline requirements for aerial lifts in the United States. These standards required employers to provide fall protection, electrical hazard control, and safe operating procedures, along with compliant equipment. Additional clauses such as 1926.20(b) and 1926.21 covered general safety programs and training obligations. Outside the US, frameworks like Australian standard AS2550.10-2006 specified inspection and maintenance regimes for Elevated Work Platforms, including quarterly, annual, and major 10‑year inspections. Global best practice converged on mandatory pre-start inspections, documented maintenance, and model-specific procedures aligned with manufacturer instructions.

Common Accident Modes: Tip-Overs, Falls, Electrocution

Tip-overs represented one of the most severe accident modes for Mobile Elevating Work Platforms, yet most incidents were preventable. Root causes included operation on slopes steeper than manufacturer limits, driving while elevated, improper outrigger deployment, and exceeding rated platform capacity. Falls occurred when operators bypassed guardrails, left access gates open, climbed on mid-rails, or used the platform as a ladder substitute. Electrocution risks arose when operators violated minimum approach distances, typically at least 3 m from energized conductors, or misjudged arcing distances in wet or polluted atmospheres. Accident statistics from OSHA showed that the majority of aerial lift incidents happened during actual operation, highlighting the importance of robust pre-use checks and conservative operating envelopes.

Employer Duties, Training, And Retraining Triggers

Employers had a legal duty to ensure only trained and authorized personnel operated MEWPs. Training needed to cover fall, electrical, struck-by, and falling-object hazards, as well as safe operating procedures, emergency controls, and specific limitations of each model. Regulations required site- and equipment-specific instruction, including review of operation manuals and hands-on practice under supervision. Retraining became mandatory after incidents, observed unsafe behavior, changes in workplace conditions, or introduction of a different aerial lift type. Employers also had to enforce removal from service of defective equipment, maintain inspection and training records, and verify that work planning respected load ratings, ground bearing capacity, and environmental limits such as maximum allowable wind speed.

Structured Inspection Regimes And Checklists

Structured inspection regimes for aerial work platforms (AWPs) and mobile elevating work platforms (MEWPs) supported systematic risk control. Operators, supervisors, and maintenance engineers relied on layered checklists to detect defects early and maintain regulatory compliance. A clear separation between pre-use checks, work area assessments, periodic engineering inspections, and model-specific items reduced blind spots and improved traceability. The following subsections described how to structure these regimes into a coherent, auditable system.

Daily Pre-Use Technical And Safety Checks

Daily pre-use checks occurred before each shift and before operating the MEWP. Operators performed a technical inspection and a safety-focused review, both documented on a standardized form. Technical checks covered operational and emergency controls, interlocks, emergency lowering, indicator lights, motion alarms, and control panel condition. Inspectors examined structural members for cracks or deformation, verified guardrails and gates, inspected tires and wheels, and confirmed braking devices and steering function. They checked fluid levels, including hydraulic oil, engine oil, coolant, and battery electrolyte, and verified outriggers and associated alarms where fitted. Safety checks addressed personal fall arrest equipment, platform cleanliness, housekeeping, and slip or trip risks. Operators verified loads would remain within rated capacity and that platform placards were legible. Any defect affecting safety required tagging the MEWP “Out of Service” and notifying a supervisor, with operation prohibited until a qualified person completed repairs and sign-off.

Work Area Hazard Surveys And Stability Assessment

Work area inspections complemented machine checks by addressing environmental and layout hazards. Before elevation, operators surveyed for drop-offs, floor openings, soft ground, and uneven or sloped surfaces that could compromise stability. They confirmed ground bearing capacity, especially on suspended structures such as bridges, mezzanines, or truck decks, and compared conditions against manufacturer slope limits, typically around 5% when elevated. The survey included overhead obstructions, low ceilings, pipework, and potential entanglement with cables, hoses, or branches. Operators evaluated proximity to energized power lines, maintaining at least 3 m clearance and respecting Minimum Safe Approach Distance guidance. They established exclusion zones using cones, barriers, and signage to separate the MEWP from pedestrians and vehicles. Weather assessments considered wind speed, storms, rain, ice, and fog against manufacturer limits for wind and exposure. Finally, operators checked that outriggers or stabilizers sat on firm, level pads, wheel chocks were used on allowable slopes, and the platform was never tethered to external structures.

Quarterly, Annual, And Major Inspection Intervals

Periodic inspections by competent technicians supported long-term structural and functional integrity. Many regimes used quarterly or 90-day inspections to review wear, fatigue, corrosion, and leakage on key components such as booms, scissor arms, pins, bushings, chains, and hydraulic hoses. These checks verified calibration and operation of safety devices, including tilt sensors, load-sensing systems, limit switches, and emergency stops. Annual inspections were more detailed and could involve partial dismantling to access hidden components and verify corrosion protection, weld integrity, and internal wear. Inspectors tested control functions under load, measured hydraulic pressures, and sampled fluid condition for contamination. Major inspections occurred at defined service life milestones, for example at ten years and then every five years for elevated work platforms under Australian practice. These involved extensive disassembly, non-destructive testing of structural elements, full replacement of time-expired items such as hoses and chains, and revalidation against current safety standards. After major inspection, a functional test program verified stability, braking, emergency lowering, and all interlocks before returning the MEWP to service.

Customizing Checklists For Specific MEWP Models

Model-specific customization ensured that generic checklists captured all relevant features and options. Engineers started with the manufacturer’s manual, extracting inspection points for unique systems such as articulating jibs, extendable axles, oscillating axles, insulated booms, or secondary guarding devices. Machines with outriggers, auto-level systems, or load-sensing platforms required additional items on daily and periodic forms to verify sensors, alarms, and control logic. For electric and hybrid MEWPs, checklists included battery condition, charging systems, insulation integrity, and any high-voltage interlocks. Telemetry and digital tools, such as QR code-based apps and telematics platforms, supported customized digital checklists and automated logging of inspection status, alarms, and utilization data. Custom forms still had to preserve

Maintenance Engineering For Reliability And Compliance

Maintenance engineering for aerial work platforms (AWPs) focused on preventing failures that could lead to accidents or costly downtime. A structured maintenance regime aligned with manufacturer instructions and regulatory standards supported safe, reliable operation throughout the equipment life. Engineers integrated hydraulic, structural, mechanical, and electrical checks with robust documentation to demonstrate compliance during audits. The following subsections outlined the core technical practices that underpinned reliable and compliant AWP fleets.

Hydraulic System Health, Fluids, And Leak Control

The hydraulic system determined lifting performance, positioning accuracy, and overall platform stability. Daily checks usually verified fluid levels, visible leaks, hose damage, and cylinder integrity before operation. Weekly and monthly tasks extended to inspecting hoses, fittings, and seals for abrasion, corrosion, or weeping, and confirming that all protective sleeves and clamps remained secure. Annual inspections by qualified technicians typically included functional tests of lift and drive circuits, pressure setting verification, and condition assessment of pumps, valves, and actuators.

Hydraulic oil selection followed ambient temperature and manufacturer guidance. Operators used ISO VG 46 anti-wear hydraulic oil above approximately 15 °C and ISO VG 32 between about -5 °C and 15 °C, unless the manual specified otherwise. For new machines, maintenance teams cleaned the tank and filters and replaced oil after about 200 operating hours to remove manufacturing residues. Under normal conditions, oil change intervals of six months were common, shortened in dusty or high-load environments to limit contamination and viscosity degradation. Technicians flushed systems by routing the return line to a container, circulating new oil until clean, then reconnecting and topping to the specified level.

Cleanliness standards were critical. Mechanics cleaned tanks and components using approved solvents such as kerosene, dried them thoroughly, and pre-rinsed with clean working oil before refilling. They never removed or bypassed filler neck strainers, which prevented particulate ingress. Air trapped in circuits caused cylinder chatter and noise, so technicians cycled cylinders fully to purge air back to the reservoir. They monitored hydraulic oil temperature, which should not exceed about 45 °C in normal duty; rapid temperature rises suggested blocked coolers, faulty relief valves, or misadjusted pressure settings. Any damaged hose or fitting required immediate replacement with parts of identical pressure rating and specification, with ports descaled and cleaned to avoid leaks or burst failures.

Structural, Mechanical, And Electrical Integrity Checks

Structural integrity inspections focused on the boom, scissor stacks, chassis, and weldments that carried platform loads. Daily visual checks looked for cracks, deformation, corrosion, loose fasteners, and missing pins or retaining clips. Quarterly and annual inspections were more detailed and sometimes required partial dismantling to examine pivot pins, bushings, and attachment points for wear or elongation. Inspectors measured clearances against manufacturer tolerances and replaced components that approached wear limits to maintain stiffness and alignment. Guardrails, toeboards, access gates, and anchorage points also required verification to ensure fall protection systems remained effective.

Mechanical systems such as drive trains, brakes, steering linkages, and outriggers or stabilizers directly affected maneuvering and stability. Weekly and monthly routines checked brake performance, parking brake holding capability on specified slopes, and correct deployment and locking of outriggers. Technicians inspected chains, cables, and pulleys for corrosion, broken wires, or incorrect tension, and confirmed that platform leveling mechanisms operated smoothly. Any deviation from rated performance or unusual noise triggered removal from service until a qualified person completed repairs and functional tests.

Electrical integrity checks covered both power and control circuits. Daily pre-use checks verified operation of emergency stops, limit switches, interlocks, motion alarms, lights, and backup alarms. Monthly and annual inspections examined wiring harnesses for abrasion, loose connectors, and insulation damage, paying particular attention to articulated joints and high-vibration areas. In humid or corrosive environments, engineers inspected enclosures for moisture ingress and corrosion, used moisture absorbers where appropriate, and ensured all gaskets and seals remained intact. Battery systems required periodic checks of charge state, electrolyte levels for flooded batteries, cable tightness, and cleanliness of terminals to avoid voltage drops and unexpected shutdowns.

Lubrication, Tires, And Thermal Management

Lubrication reduced wear at pivot points, bearings, and

Summary Of Key Controls And Engineering Takeaways

Aerial work platform safety relied on a layered control strategy that combined engineering design, inspection, maintenance, and operator behavior. Incident data showed that most accidents occurred during operation, so robust pre-use checks and disciplined work area assessments provided the highest risk reduction at lowest cost. Structured inspection regimes, from daily technical and safety checks through quarterly, annual, and 10‑year major inspections, ensured that wear, corrosion, and hidden defects did not erode original design safety margins. These regimes had to align with OSHA requirements or local standards such as AS2550.10, and follow manufacturer instructions for each MEWP family and model.

From an engineering perspective, hydraulic integrity, structural soundness, and electrical safety formed the three critical technical pillars. Correct fluid specification versus ambient temperature, leak-free circuits, and controlled oil temperature preserved actuator performance and stability. Periodic dismantling and non-destructive examination of booms, welds, pins, and attachment points validated that the structure still carried rated loads with adequate fatigue life. Electrical and control systems required moisture protection, functional verification of emergency stops, interlocks, alarms, and accurate load and capacity indication.

Future practice increasingly integrated telematics, digital checklists, and QR‑based access to manuals and training content to close gaps between design intent and field use. These tools supported condition-based maintenance, earlier fault detection, and more consistent operator training and retraining. However, they complemented rather than replaced competent mechanics, documented inspections, and a conservative approach to ground conditions, slopes, wind, and proximity to energized conductors. Organizations that embedded these controls into their asset lifecycle planning achieved higher equipment availability, lower life-cycle cost, and sustained regulatory compliance while reducing severe events such as tip-overs, falls, and electrocutions.