Electric compact scissor lifts answered a clear need in modern plants, warehouses, and service facilities for safe elevation in tight spaces. This article explained how their compact scissor geometry, electric actuation, and stability metrics shaped performance and compliance. It then mapped what are the applications of an electric compact scissor lift across manufacturing, warehousing, retail, maintenance, and precision environments.

Later sections compared advantages, limits, and selection trade-offs between electric and hydraulic designs, with focus on ergonomics, lifecycle cost, and reliability. The final guidance section tied these points into practical implementation steps so engineering, safety, and operations teams could specify, deploy, and maintain compact electric scissor lifts as part of a coherent access and material handling strategy.

Core Design And Performance Characteristics

Core design features of electric compact scissor lifts decide where they fit best and how safely they work. Engineers who ask what are the applications of an electric compact scissor lift must first understand geometry, load paths, actuation, and control logic. These factors set limits for capacity, height, stability, and safety, especially in tight indoor spaces. The following sections explain how these design choices translate into real performance on the shop floor.

Compact Scissor Geometry And Load Paths

Compact scissor geometry uses crossed arms that form a series of linked X-frames. The structure carries vertical loads as axial forces in the arms and shear in pins and bushings. Short wheelbases and narrow chassis widths allow operation in aisles and between workstations.

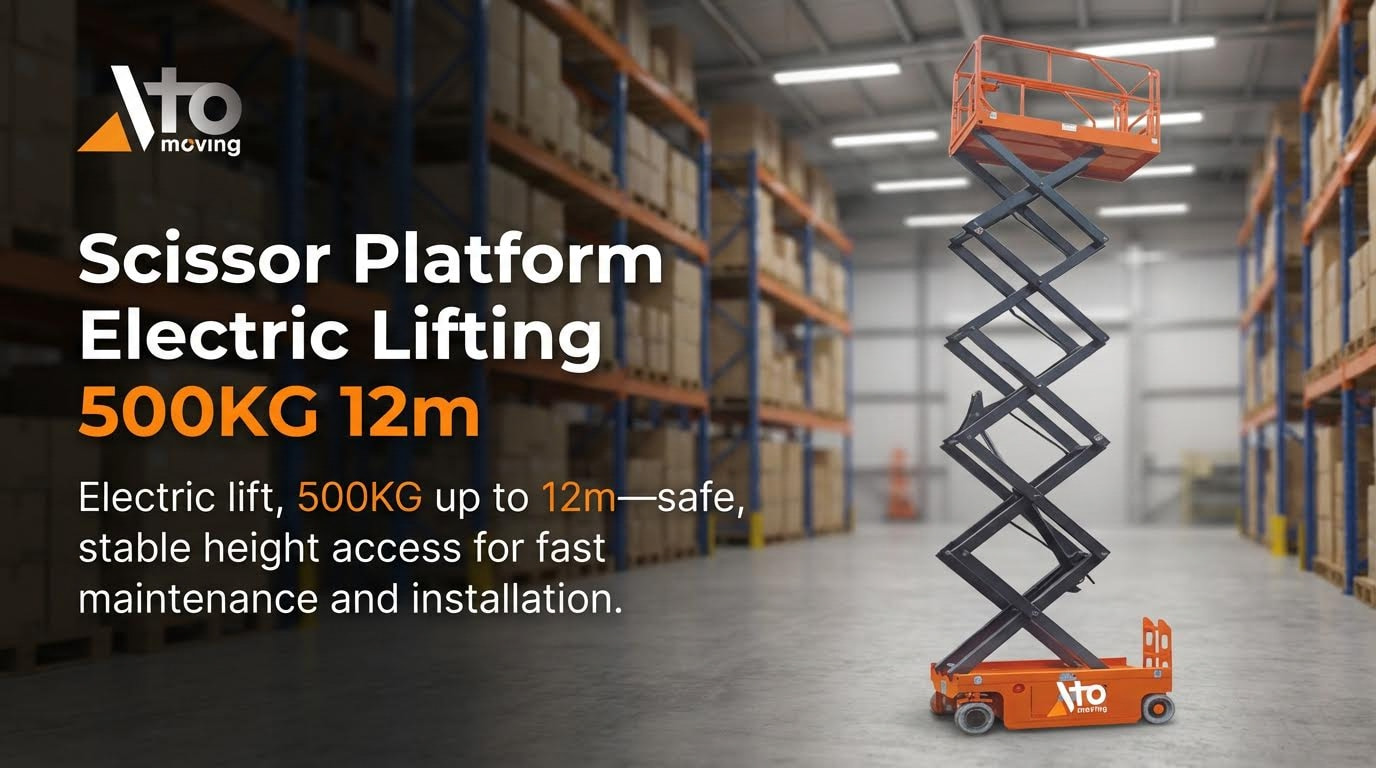

Designers keep the center of gravity within the support polygon across the full stroke. This governs platform size, outreach, and rated load. Typical compact units target light to medium loads, often below 500 kilograms. They prioritize small footprint and maneuverability over extreme height or capacity.

Key geometric choices include:

- Arm length and thickness, which set stiffness and deflection.

- Base width, which sets tipping margin during travel and elevation.

- Platform overhang, which affects moment loads in the scissor stack.

Finite element checks and stability calculations verify that stresses and deflections stay within limits at maximum rated load and height.

Electric Actuation, Duty Cycles, And Control

Electric compact scissor lifts usually use electro-mechanical or electro-hydraulic actuation. Electro-mechanical designs use screw or belt drives and avoid fluid leaks. Electro-hydraulic designs use electric pumps with compact cylinders to gain higher force density.

Typical duty cycles are intermittent. Many models are rated for a few lifts per hour in normal industrial shifts. Continuous cycling at maximum load shortens motor and drive life, so control systems often monitor temperature and usage.

Modern control packages include:

- Proportional joysticks for smooth speed control.

- Soft-start and soft-stop ramps to limit shock loads.

- Interlocks that block lift if overload or tilt limits trigger.

Battery-powered systems support indoor applications because they emit no exhaust. Charge times and ampere-hour capacity then define practical daily utilisation windows.

Key Performance Metrics: Capacity, Height, Stability

Three headline metrics shape both design and application choices: rated capacity, maximum platform height, and stability margins. Compact electric units usually focus on lighter loads and moderate heights that match indoor tasks. Typical catalog data show capacities up to a few hundred kilograms and platform heights suitable for workstation, shelving, and ceiling access.

Engineers evaluate:

| Metric | Typical focus range | Application impact |

|---|---|---|

| Rated capacity | Light to medium loads (≤500 kg) | Component handling, tools, cartons, small equipment |

| Platform height | Workstation to mid-height access | Assembly lines, racking, lighting, signage |

| Stability factor | Safety factor against overturn | Safe use in narrow aisles and tight spaces |

Stability depends on base width, wheel track, and platform loading pattern. Load-sensing systems and height limiting under adverse conditions further protect against tip events.

Safety Systems And Regulatory Compliance

Safety systems ensure that compact electric scissor lifts meet standards such as ANSI/SAIA and ISO 16368. Designers integrate mechanical, electrical, and electronic layers of protection. These layers reduce risk during lifting, travel, and maintenance.

Common safety features include:

- Guardrails and toe boards around the platform.

- Emergency stop buttons at platform and base controls.

- Tilt sensors that restrict elevation on sloped floors.

- Load sensors that prevent operation above rated capacity.

- Descent limiting valves and mechanical locks for controlled lowering.

Automatic pothole protection and speed reduction at height further cut tip-over risk in self-propelled models. Compliance also covers labeling, operator instructions, and regular inspection intervals. When plants study what are the applications of an electric compact scissor lift, they should match these safety functions with site rules, floor conditions, and required working heights before deployment.

Typical Industrial And Commercial Applications

Engineers who ask what are the applications of an electric compact scissor lift usually work in tight, indoor spaces. These lifts support light to medium loads on flat floors where access, ergonomics, and cleanliness matter more than extreme height. They suit repeatable tasks with controlled duty cycles and predictable travel paths. The following use cases show how different sectors integrate compact platforms into daily operations.

Manufacturing, Assembly, And Ergonomic Workstations

In manufacturing, electric compact scissor lifts position parts, bins, and subassemblies at elbow height. This reduces bending and overreach, which lowers musculoskeletal risk and improves cycle consistency. Typical stations include electronics assembly, light mechanical build, kitting, and packing cells.

Engineers often configure these tables as part of lean lines. Common uses include:

- Feeding small components to operators at fixed height.

- Supporting jigs, fixtures, or test rigs during build and inspection.

- Acting as adjustable-height workbenches for rework or quality checks.

Electric actuation allows precise, repeatable setpoints, which supports standardized work instructions. The compact footprint lets designers place lifts between conveyors, AGV lanes, or racking without changing the overall line layout.

Warehousing, Retail, And High-Density Storage Access

In logistics and retail, electric compact scissor lifts answer a key question: what are the applications of an electric compact scissor lift when aisles are narrow and stock is light. These units raise operators, totes, or cartons to low and mid-level shelves. They work best where rack heights stay within the limited platform stroke.

Typical warehouse and retail tasks include:

- Order picking from shelving in high-density storage zones.

- Shelf replenishment in back-of-house and sales floors.

- Installing or adjusting light racking, guards, and small signs.

Compared with larger self-propelled scissors, compact models fit through standard doors and small elevators. They often roll manually or with simple powered drive, which reduces weight and floor loading. Quiet, zero-emission operation allows use during trading hours without disturbing customers or triggering HVAC alarms.

Facility Maintenance, MEP, And Fit-Out Activities

Maintenance teams use compact scissor lifts for short-duration work at modest heights. Electric drives avoid exhaust, which is critical in offices, schools, airports, and hospitals. The stable platform supports tools and small components for building systems.

Common applications include:

- Changing lamps, sensors, and emergency lighting.

- Servicing HVAC diffusers, grilles, and low ductwork.

- Running cable trays, low-level conduit, and interior signage.

During fit-out projects, compact units replace step ladders and small towers. They reduce climb cycles and improve three-point contact, which lowers fall risk. Their small turning radius helps crews work in corridors, washrooms, and plant rooms without moving large furniture or equipment.

Cleanrooms, Labs, Tech, And Precision Handling

Clean and technical spaces highlight another answer to what are the applications of an electric compact scissor lift. Here the priority is particle control, low noise, and precise motion. Electric compact lifts meet these needs because they operate without combustion and avoid hydraulic oil exposure when electro-mechanical drives are used.

Typical clean and tech tasks include positioning:

- Instrumentation racks, analyzers, and test setups in labs.

- Wafer cassettes, trays, or carriers in semiconductor lines.

- Delicate servers, storage arrays, or AV hardware during installation.

Stainless or coated platforms, smooth welds, and sealed casters help meet cleanliness classes when specified. Fine speed control supports millimetre-level placement of sensitive devices. Compact geometry keeps the lift inside laminar flow zones and under ceiling-mounted filters, which preserves airflow patterns and contamination control.

Advantages, Limitations, And Selection Trade-Offs

Engineers asking what are the applications of an electric compact scissor lift must weigh advantages, limits, and trade-offs. Electric compact units fit tight indoor spaces, support light to medium loads, and offer precise elevation. This section explains how these benefits compare with technical constraints, lifecycle economics, and hydraulic alternatives.

Operational And Ergonomic Advantages Indoors

Electric compact scissor lifts support repetitive vertical handling in tight footprints. Typical industrial use includes assembly lines, kitting cells, packing stations, and test benches. Operators raise loads to elbow height, which cuts bending, reaching, and twisting. This reduces fatigue and supports higher cycle counts per shift.

Battery-electric drives remove exhaust emissions. This protects indoor air quality in warehouses, terminals, and clean production areas. Noise levels usually stay well below common occupational limits, which helps verbal communication near the lift. Compact wheelbases and narrow chassis allow navigation through standard doors and narrow aisles.

Control systems often provide smooth, proportional lift and lower. This helps when positioning delicate parts, fixtures, or instruments. In labs and electronics work, small vertical adjustments protect sensitive assemblies from impact or drop. For facilities that ask what are the applications of an electric compact scissor lift, these ergonomic gains make them ideal for light assembly, order picking, and indoor maintenance at moderate heights.

Technical Limitations And Misapplication Risks

Electric compact scissor lifts have clear technical bounds. Platform capacities typically stay in the light to medium range. Maximum lift height remains moderate compared with large construction scissor lifts. These limits define where the machines fit and where they do not.

Misapplication often appears when users treat compact lifts like heavy-duty access platforms. Overloading the deck, adding unapproved extensions, or using the lift on uneven floors raises tip and structural risks. Using indoor-rated wheels on rough concrete or ramps also degrades stability and braking.

Battery systems restrict continuous duty. Long, high-frequency cycles without charging shorten runtime and battery life. Incorrect chargers or poor charging habits accelerate capacity loss. For teams evaluating what are the applications of an electric compact scissor lift, engineers should avoid outdoor construction, heavy steel fabrication, and long-duration elevated work at higher heights.

To reduce risk, match each model against four checks: rated capacity, maximum height, floor condition, and duty cycle. If any item exceeds specification, select a different lift class or redesign the task flow.

Lifecycle Costs, Maintenance, And Reliability

Electric compact scissor lifts usually trade higher purchase price for lower running cost. Electric actuation and compact mechanisms reduce energy use compared with engine-driven units. There is no fuel system and no exhaust after-treatment. This simplifies routine service.

Key maintenance tasks include periodic structural inspection, lubrication of pivot points, battery care, and checks of limit switches and safety interlocks. Many electric designs avoid hydraulic circuits, which removes leak risk and fluid replacement. Where electro-hydraulic drives exist, fluid, seals, and hoses still require inspection.

Lifecycle cost analysis should include energy, scheduled service, consumables, and downtime. Digital maintenance logs or fleet software help track hours and plan service windows. This prevents unplanned stoppages during peak shifts.

In applications like packing lines, small parts assembly, or lab handling, uptime and cleanliness carry high value. Here, an electric compact scissor lift often delivers better cost per productive hour than larger or engine-powered alternatives. When engineers ask what are the applications of an electric compact scissor lift, they should link each use case to expected duty hours and service access.

Selecting Between Electric And Hydraulic Scissor Lifts

Selection between electric and hydraulic scissor lifts depends on load, height, environment, and duty profile. Electric compact units work best indoors on flat, finished floors. Typical uses include order picking, light assembly, tool elevation, and maintenance below high ceiling levels. They offer precise positioning, low noise, and zero local emissions.

Hydraulic scissor lifts suit heavier loads and harsher sites. They handle higher capacities and greater lift heights and often accept rougher terrain. This makes them common in steel fabrication, outdoor construction, and heavy equipment service bays. However, hydraulic fluid leaks can threaten cleanrooms, food plants, and electronics production.

A structured comparison helps:

| Criterion | Electric Compact | Hydraulic (Heavy) |

|---|---|---|

| Typical application | Indoor light-duty, precision work | Heavy-duty, construction, outdoor |

| Environment | Clean, low noise, zero emissions | Less sensitive to noise and spills |

| Control | High positioning accuracy | Smooth but less precise |

| Maintenance | Lower, battery-focused | Higher, fluid and seals |

When defining what are the applications of an electric compact scissor lift, engineers should favor electric where cleanliness, ergonomics, and fine control outrank extreme capacity or height. Mixed fleets are common. Indoor tasks run on electric compacts, while outdoor or heavy fabrication work stays with hydraulic platforms.

Summary And Strategic Implementation Guidance

Electric compact scissor lifts suited indoor tasks where space, air quality, and precision matter. They handled light to medium loads at modest heights and offered clean, quiet operation with tight maneuvering. Answering the query what are the applications of an electric compact scissor lift required a joined view of design, performance, and safety. Strategic deployment depended on matching these traits with workflow, duty cycle, and facility constraints.

Key findings showed the strongest use cases in manufacturing cells, packing lines, retail aisles, laboratories, and indoor maintenance. Typical roles included work positioning, ergonomic load lifting, and safe access to ceilings, racking, and services within about 2 metres. Electric drives reduced energy use and emissions versus engine or fully hydraulic units, while integrated sensors, interlocks, and standards compliance raised safety margins. Limits on capacity, height, and terrain capability meant they were poor choices for heavy construction or rough outdoor work.

Implementation worked best when engineers defined tasks in detail. They specified load envelopes, lift cycles per shift, floor conditions, and clearance around racking, conveyors, or benches. This data supported correct sizing, platform selection, and guardrail or gate options. It also guided charging infrastructure, inspection intervals, and operator training.

Looking ahead, tighter emission rules and denser facilities would keep shifting demand toward compact electric platforms. Controls would likely add more diagnostics, geo-fencing, and speed or height limiting tied to load and location. Yet core trade-offs would stay: electric compact scissor lifts would remain ideal for clean, flat, indoor work and unsuited to heavy, high, or off-road lifting. Sites that treated them as part of a system, together with conveyors, overhead handling, and tools from suppliers such as Atomoving, would gain the best long-term value.