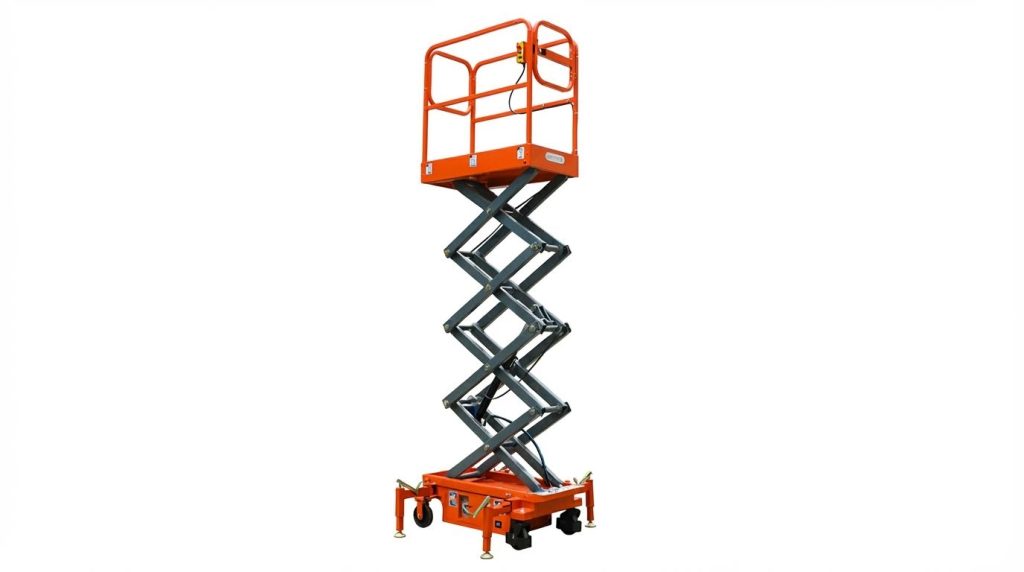

Electric scissor lifts provided compact, vertically translating work platforms for industrial, construction, and maintenance tasks. Their design integrated scissor linkages, hydraulic actuation, and motion control to deliver safe, repeatable elevation on constrained sites. Power architectures evolved from flooded lead-acid batteries to LiFePO4 and emerging solid-state systems, coordinated by advanced battery management and telematics. This article examined operating principles, power and battery technologies, safety standards, and application engineering to support robust selection and deployment decisions for modern electric scissor lifts.

Core Design And Operating Principles

Core design and operating principles defined how electric scissor lifts delivered vertical access with controlled motion and high safety margins. Engineers combined a pantograph-style mechanical linkage, hydraulic or electro-hydraulic actuation, and closed-loop control logic to generate stable elevation under varying loads. Understanding these fundamentals allowed correct model selection, safe operation, and effective troubleshooting across industrial sites.

Scissor Mechanism And Motion Control

The scissor mechanism used crossed steel arms pinned at the center to form a pantograph that translated linear actuator stroke into vertical platform motion. Designers sized arm section modulus, pin diameters, and joint clearances to limit deflection and ensure fatigue life under rated loads plus dynamic factors. Electric scissor lifts typically used a single central cylinder or screw drive acting on the lower arm set, with guide rails or sliding shoes constraining lateral movement. Motion control relied on proportional valve or motor control to modulate lift speed, allowing gradual starts, smooth stops, and fine positioning near work surfaces. Interlocks in the control logic prevented platform elevation when stabilizers were not deployed or when the chassis was out of level beyond specified limits.

Hydraulic Circuits, Valves, And Cylinders

Most electric scissor lifts employed compact hydraulic power packs with an electric motor, gear pump, reservoir, and manifold block. The circuit included check valves to hold pressure, relief valves to cap system pressure, and lowering valves that controlled descent rate under load. Cylinders converted hydraulic pressure into force on the scissor linkage; designers specified bore, rod diameter, and stroke to match rated capacity and lift height with adequate safety factors. Operators needed to inspect cylinders and hoses for leaks, abrasion, and deformation, because hydraulic failure could cause uncontrolled descent or loss of lift capability. Abnormal noise, rapid oil temperature increase, unexpected pressure spikes, or sluggish response indicated circuit faults and required immediate shutdown and diagnostic checks of pumps, valves, and oil condition.

Operator Controls And Functional Checks

Operator interfaces typically consisted of ground and platform control stations with key switches, joysticks or rocker switches, emergency stop buttons, and indicator lamps. The control system governed lift, lower, drive, and steering functions, often using low-voltage control circuits that actuated higher-power hydraulic or traction components. Before work, operators had to conduct functional checks: energize the system, test emergency stop, raise and lower the platform a few centimetres, and verify guardrail gates and interlocks. Standards required clear labeling of maximum platform load near the controls, along with pictograms for direction of motion and emergency procedures. Training emphasized keeping all controllers at neutral during power loss and knowing manual-lowering procedures so the platform could return safely to ground in a fault condition.

Stability, Center Of Gravity, And Tipping Risks

Stability analysis considered the combined center of gravity (CoG) of chassis, structure, batteries, occupants, and tools relative to the support polygon defined by the wheels or outriggers. As the platform rose, the CoG moved upward, reducing the allowable horizontal offset before the overturning moment exceeded the restoring moment from the machine’s weight and footprint. Manufacturers therefore limited rated load, lateral outreach, and allowable slope; operators had to keep loads within guardrails and avoid leaning or climbing on rails, which shifted the CoG outward. Flat, firm ground was mandatory; on uneven surfaces, specified outriggers or stabilizers increased the effective base width and improved tipping resistance. Wind loading, impact from adjacent equipment, and travel with the platform elevated further increased overturning risk, so procedures restricted travel height and prohibited operation in strong winds or storms.

Power Sources And Battery Technologies

Electric scissor lifts relied on electrochemical energy storage, with the battery system dictating duty cycle, response, and maintenance. Engineers matched battery chemistry, voltage, and capacity to platform mass, duty profile, and ambient conditions. Powertrain choices also affected noise, emissions, and indoor air quality, which drove the shift toward electric units for warehouses and factories. Within this context, lead-acid and LiFePO4 architectures represented the dominant options, with emerging solid-state variants under evaluation for high-utilization fleets.

Lead-Acid Vs. LiFePO4 Battery Architectures

Traditional electric scissor lifts used flooded or sealed lead-acid batteries due to low upfront cost and established supply chains. These batteries operated at nominal voltages such as 24 V or 48 V, with capacities sized to support a single shift before recharging. However, lead-acid units required watering, equalizing charges, and periodic cleaning to control sulfation and corrosion. LiFePO4 batteries, in contrast, provided higher usable depth of discharge, typically up to 80–100% without accelerated degradation. They exhibited cycle life exceeding 5,000 cycles at 80% depth of discharge, roughly ten times that of industrial lead-acid packs. Their stable P–O bond structure improved thermal and chemical stability, reducing risk of thermal runaway and fire. As a result, LiFePO4 architectures became attractive for high-duty indoor fleets and rough-terrain platforms needing long runtimes and fast turnaround.

BMS, Charging Profiles, And Thermal Limits

Lead-acid batteries used relatively simple charge control, often following bulk–absorption–float algorithms with tight voltage limits to avoid gassing. In contrast, LiFePO4 packs integrated sophisticated Battery Management Systems (BMS) to monitor cell voltages, currents, and temperatures in real time. The BMS enforced charge and discharge current limits, cut off the pack during overcharge, over-discharge, or short circuits, and balanced cells to maintain uniform state of charge. Charging profiles for LiFePO4 supported higher C-rates, enabling fast charging and opportunity charging during short breaks. Manufacturers specified operating windows, for example discharge between −20 °C and 60 °C and charging between 0 °C and 55 °C, which the BMS enforced. Optional heating modules allowed safe charging at sub-zero temperatures down to approximately −20 °C. These controls reduced failure rates and ensured predictable performance in harsh industrial environments.

Energy Efficiency, Runtime, And Lifecycle Cost

LiFePO4 batteries delivered higher round-trip efficiency than lead-acid, which reduced wasted energy and heat generation during charging and discharging. Higher usable capacity meant that a LiFePO4 pack of a given nominal ampere-hour rating supported longer runtimes between charges. For scissor lift fleets, this translated into fewer mid-shift battery changes and less unplanned downtime. Although LiFePO4 systems carried higher initial purchase cost, their extended cycle life and maintenance-free operation lowered total cost of ownership. Fleet operators avoided labor for watering, equalizing, and cleaning, and they reduced replacement frequency over the equipment’s life. When combined with faster charging, these factors improved utilization rates of lifts in rental yards, construction sites, and logistics hubs. Lifecycle analyses increasingly favored LiFePO4 where utilization exceeded occasional or light-duty operation. Lead-acid remained viable for low-intensity applications with tight capital budgets and limited daily run hours.

Trends: Solid-State, Telematics, And AI Monitoring

Solid-state LiFePO4 variants, such as 48 V 150 Ah packs, emerged for heavy-duty scissor lifts and aerial work platforms. These designs used solid electrolytes and robust enclosures with ingress protection ratings up to IP67, which enhanced resistance to dust and temporary water immersion. Integrated BMS units interfaced with telematics modules, enabling remote monitoring of state of charge, temperature, and fault codes over wireless networks. Bluetooth connectivity allowed local diagnostics via handheld devices, supporting quick troubleshooting and predictive maintenance. AI-based analytics platforms processed fleet battery data

Safety, Standards, And Application Engineering

Safety engineering for electric scissor lifts relied on codified standards, structured risk assessment, and disciplined operating procedures. Designers and fleet managers integrated mechanical safeguards, electronic interlocks, and procedural controls to achieve acceptable residual risk. Standards such as ISO 16368 and OSHA/EN regulations defined minimum requirements for guardrails, stability, controls, and testing. Application engineering then matched lift configuration, power source, and safety features to the specific site environment and duty cycle.

Pre-Use Inspection And Preventive Maintenance

Pre-use inspections functioned as the primary barrier against in-service failures. Operators checked structural elements for cracks, deformation, corrosion, and loose fasteners, with particular focus on scissor pins, welds, and platform anchorage points. Hydraulic circuits required inspection for external leaks, damaged hoses, deteriorated seals, and abnormal noise or temperature rise during test operation. Standards and OEM manuals mandated verification of guardrails, gates, toe boards, and emergency stop buttons before elevation.

Electrical systems also required systematic checks. Operators confirmed battery state of charge, cable insulation integrity, connector locking, and the absence of exposed conductors. Functional tests included raising and lowering the platform a short distance to confirm smooth motion, correct speed, and response to emergency stop and descent controls. Preventive maintenance schedules defined periodic fluid sampling, filter replacement, torque checks on structural joints, and calibration of limit switches and tilt sensors. Documented inspection records supported regulatory compliance and trend analysis for condition-based maintenance.

Load Rating, Platform Design, And Guardrails

Load rating governed structural sizing of the scissor stack, platform deck, and chassis. Engineers specified a rated load that included personnel, tools, and materials, with safety factors applied to yield and buckling limits according to relevant standards. Labels at the control station indicated maximum permissible mass and sometimes separate limits for point loads and side loads. Application engineers instructed operators to verify combined weight of occupants and equipment against this rating before elevation.

Platform design balanced usable area, stiffness, and mass. Decks incorporated non-slip surfaces, drainage paths, and tie-down points to secure tools and materials, reducing dropped-object risks. Guardrail systems generally met OSHA or EN dimensional requirements for height, mid-rails, and toe boards, with self-closing gates or interlocked doors. Operators maintained their bodies within the guardrail envelope and avoided climbing or leaning over rails to prevent loss of balance. Where regulations required, personal fall protection systems supplemented guardrails, especially for atypical tasks or non-standard configurations.

Site Conditions, Weather, And Ground Bearing

Site assessment addressed ground bearing, slope, access paths, and overhead obstructions. Engineers evaluated soil bearing capacity, slab thickness, and subgrade conditions to ensure contact pressures from wheels or outriggers remained below allowable values. On concrete or industrial floors, this involved checking for voids, trenches, and damaged joints. On unpaved sites, the design of rough-terrain models factored in larger tire footprints and optional outriggers to distribute load.

Standards and OEM instructions limited operation to level, stable surfaces within specified maximum grades for travel and elevation. Operators avoided holes, ramps, and backfilled areas that could settle under load. Weather conditions introduced additional constraints. High winds, rain, ice, and lightning increased tipping and slip risks and reduced visibility. Manufacturers specified maximum allowable wind speeds for outdoor use, above which elevation was prohibited. Application engineering therefore included site-specific operating envelopes, barricading of the work zone, and clear vertical and lateral clearances around the platform.

Indoor Vs. Rough-Terrain Deployment Choices

Deployment decisions differentiated indoor electric slab lifts from rough-terrain units. Indoor models typically used electric drive, solid non-marking tires, and compact chassis dimensions to navigate aisles and finished floors. Their lower machine mass and tighter turning radius suited warehouses, factories, and maintenance tasks on smooth concrete. Zero local emissions and low acoustic noise allowed operation in enclosed spaces with minimal impact on occupants.

Rough-terrain scissor lifts used higher-capacity structures, larger tires, and often diesel or hybrid powertrains to handle uneven ground and outdoor duty cycles. Their mass and wheelbase increased stability at higher working heights and under wind loading. Application engineers evaluated approach angles, ground clearance, and gradeability against site profiles such as construction zones and infrastructure projects. Selection criteria therefore combined environment, surface conditions, required height, and duty duration. In mixed-use fleets

Summary And Engineering Selection Takeaways

Electric scissor lifts relied on mature mechanical, hydraulic, and control architectures, but safety and energy systems evolved rapidly. Engineers evaluated designs by integrating platform height, load rating, and stability margins with site constraints and regulatory requirements. LiFePO4 batteries, particularly solid-state and high-capacity modules, reduced lifecycle cost by extending service life beyond 5,000 cycles and eliminating watering and equalizing. These packs also improved safety through stable chemistries and advanced BMS functions that protected against overcharge, over-discharge, and over-current events.

From an industry perspective, the shift from lead-acid to LiFePO4 architectures lowered downtime, reduced mass for indoor units, and aligned with RoHS and similar environmental regulations. Electric scissor lifts with telematics-ready battery systems supported predictive maintenance by logging charge cycles, fault codes, and thermal data. Future trends pointed toward deeper integration of solid-state LiFePO4, higher-voltage architectures for improved efficiency, and AI-assisted monitoring that optimized charging profiles and flagged hydraulic or control anomalies before failure. These developments supported safer operation, especially where strict training, PPE use, and pre-use inspections were mandatory by law.

For practical implementation, engineers matched battery voltage and capacity to duty cycles, ambient temperature range, and charging infrastructure, while verifying that ground bearing capacity, platform loading, and wind limits met applicable standards. Indoor applications favored compact electric units with low emissions and lower machine mass, whereas rough-terrain work required higher ground clearance, larger tires, and higher-weight platforms with appropriate outriggers. A balanced technology view considered not only energy density and runtime, but also serviceability, parts availability, and compatibility with existing fleets. By combining rigorous safety engineering, correct power-source selection, and site-specific risk assessment, practitioners specified scissor lifts that achieved reliable, compliant, and cost-effective operation over their full service life.