Industrial scissor lifts covered in this article ranged from compact 7.7 m electric slab units to large 19+ m all‑terrain platforms, with capacities between 150 kg and 750 kg and beyond. Understanding how platform height, working height, footprint, and machine weight interacted was essential for safe selection and integration into plants, warehouses, and construction sites.

The following sections examined core dimensional concepts, load capacity versus machine mass and stability, and how powertrain and hydraulic choices affected duty cycle and lifecycle cost. The article then linked these technical parameters to standards, safety systems, and practical de‑rating rules so engineers could match specific lift models to task, building, and floor constraints.

Core Dimensions: Height, Reach, And Footprint

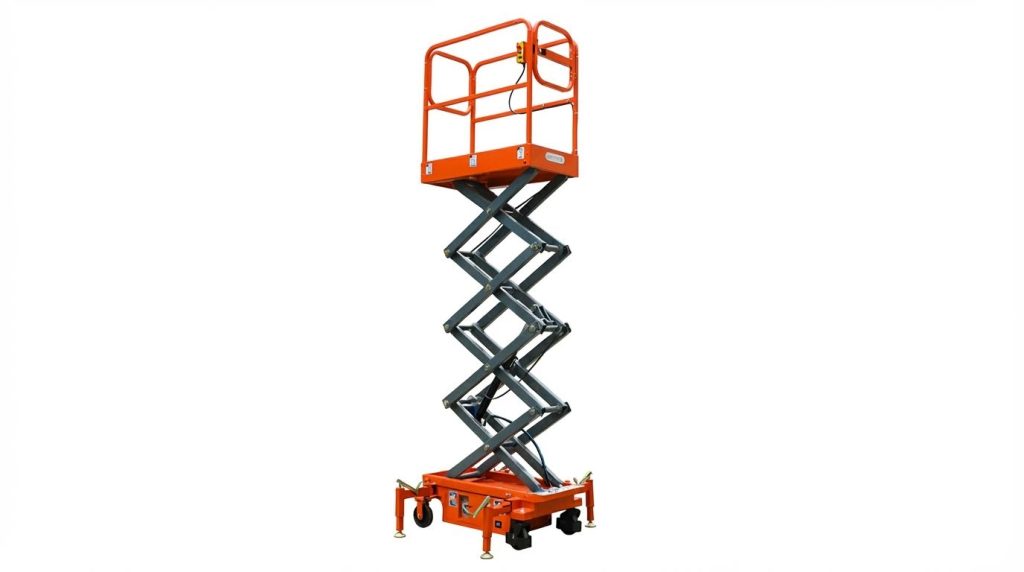

Industrial scissor lifts relied on a compact base footprint to deliver vertical reach with minimal horizontal movement. Engineers evaluated platform height, working height, and machine width together, because these parameters controlled usable reach, aisle compatibility, and floor loading. Manufacturers such as JCB, Haulotte, and others offered families of models that stepped up systematically in height and mass, allowing users to match geometry to the task. Understanding these dimensional trade‑offs reduced the risk of instability, structural overloading, and clearance conflicts in constrained industrial environments.

Platform Height Vs. Working Height Explained

Platform height described the vertical distance from the ground to the floor of the platform at full extension. Working height typically equalled platform height plus about 2.0 m, assuming an average operator could reach roughly 2.0 m above the platform. For example, the JCB S1932E had a platform height of 5.71 m and a working height of 7.71 m, while the S3246E offered 9.7 m platform and 11.7 m working height. Haulotte specified working heights directly in feet, such as 26 ft (≈7.92 m) or 63 ft (≈19.20 m), which implied corresponding platform heights approximately 2.0 m lower. When specifying a lift, users started from the required working height at the task surface, then worked backward to required platform height and model family.

Typical Size Ranges: Slab, RT, And Dock Lifts

Slab electric scissor lifts served indoor or paved-slab applications with relatively small footprints and moderate heights. Typical platform heights ranged from about 5.7 m for compact units like the JCB S1932E up to roughly 11.9 m for larger electrics such as the JCB S4046E, with working heights up to about 13.9 m. Haulotte and similar suppliers extended this range further, with electric and hybrid units achieving working heights from 7.92 m up to about 19.20 m while remaining maneuverable in industrial aisles. Rough‑terrain (RT) and all‑terrain units, such as the Haulotte Compact 3368 RT and HS‑series, used wider chassis, higher ground clearance, and stabilizers to reach working heights between about 10.06 m and 17.68 m on uneven ground. Fixed industrial dock or table lifts, including hydraulic platforms rated from 500 kg to 40 t with lift heights up to 6 m, prioritized vertical travel and capacity over mobility and typically integrated into pits or dock faces.

Platform Area, Extensions, And Person-Rating

Platform area directly influenced both ergonomic productivity and structural loading. Typical self‑propelled scissors used rectangular decks, for example 1,700 mm × 1,000 mm on DGH series lift tables, with optional slide‑out extensions on mobile access platforms. Platform extensions increased usable floor area and outreach over machinery or conveyors, but manufacturers usually specified a reduced capacity on the extension section, as illustrated by the 3 ft extension on a 19 ft Skyjack unit with a lower allowable load. Person‑rating defined the maximum number of occupants, often two on JCB S‑series and up to three on certain Haulotte models, with total mass limited by the rated capacity in kilograms. Large all‑terrain scissors, such as Haulotte HS models, combined wide platforms and high capacities up to 750 kg, enabling simultaneous work by multiple technicians plus tools while maintaining structural safety margins.

Indoor Vs. Outdoor Dimensions And Clearances

Indoor electric scissors prioritized compact width and stowed height to pass through doorways and operate between racks. Platform heights for indoor-only units, such as the JCB S2632E and S4046E, still reached 7.92 m and 11.9 m respectively, but the machines were not wind‑rated for outdoor use and relied on smooth, flat floors. Outdoor-rated models, including the JCB S1932E, S2646E, S3246E, and Haulotte rough‑terrain

Load Capacity, Machine Weight, And Stability

Load capacity, machine weight, and stability defined the safe operating envelope of industrial scissor lifts. Engineers and fleet managers evaluated these parameters together, because changing one factor usually affected the others. Manufacturers specified capacities on the assumption of level ground, correct tire or outrigger contact, and compliant operating conditions. Misinterpreting these values risked structural overload, tip-over, or floor failure.

Capacity Ranges: 150–750 kg And Beyond

Industrial scissor lifts covered a wide capacity spectrum, from light indoor units around 150 kg up to heavy-duty platforms at 750 kg and above. Electric slab scissor lifts from OEMs such as JCB and Haulotte typically offered platform capacities between roughly 230 kg and 450 kg for compact models, suitable for two or three persons plus tools. High-capacity rough-terrain and large electric scissor lifts reached 750 kg, supporting multiple operators and heavy materials for façade work or industrial maintenance. Fixed industrial scissor tables, especially hydraulic floor-mounted units, routinely exceeded mobile lift capacities, with rated loads from 500 kg up to 40,000 kg for material handling and production integration. When specifying capacity, engineers accounted for the entire load: personnel, tools, consumables, and any temporary fixtures or jigs.

Machine Operating Weight And Floor Loading

Machine operating weight directly influenced floor loading, transport logistics, and site access planning. Compact electric slab scissor lifts in the 8–12 m working height class typically weighed between about 1,500 kg and 3,000 kg, while larger outdoor electric units exceeded 3,500 kg. Industrial hydraulic lift tables with multi-scissor arrangements also carried substantial dead weight due to heavy steel structures and large cylinders. Structural engineers evaluated point loads and line loads from wheel contact patches or base frames against slab design, often using worst-case concentrated loads rather than average pressure. For mezzanines, suspended slabs, or elevated docks, checking allowable floor load in kilonewtons per square metre against the lift’s maximum wheel load was critical before deployment. Where floor capacity was marginal, operators used load-spreading mats or steel plates to reduce contact stress and prevent cracking or punching shear failures.

Center Of Gravity, Outriggers, And Wind Ratings

Stability depended strongly on the combined center of gravity (CoG) of the machine and payload relative to the support polygon. Mobile scissor lifts relied on a wide chassis, pothole protection, and, for rough-terrain models, outriggers or stabilizers to increase the effective base width. Raising the platform moved the CoG upward, reducing stability margins and making the lift more sensitive to dynamic effects such as braking or wind gusts. Manufacturers therefore assigned maximum allowable wind speeds, typically around 11–12.5 m/s (25–28 mph), and restricted certain slab models to indoor use only. Outdoor-rated units used larger wheelbases, heavier chassis, and stabilizers to maintain sufficient overturning resistance under lateral wind loads. Operators improved stability by respecting rated occupancy limits, keeping heavy materials close to the platform center, and avoiding sudden drive or steering inputs at height.

Standards, Nameplate Limits, And De-Rating Rules

Regulatory standards and manufacturer instructions governed how users interpreted load and height ratings. The platform nameplate stated maximum rated load, maximum number of occupants, allowable wind condition, and sometimes side-load limits; operating beyond these values violated both standards and warranty conditions. In Europe and many other regions, mobile elevating work platforms followed EN and ISO standards that defined test factors for structural strength and stability, while OSHA regulations in the United States treated scissor lifts as mobile scaffolds with guardrail and training requirements. De-rating rules applied when conditions deviated from the test basis, for example when using platform extensions, working in higher wind zones, or adding non-standard attachments. Fleet managers documented any engineered de-rating in site-specific lift plans, ensuring operators used the lower capacity figure in their load calculations. Consistent adherence to nameplate limits and de-rating policies significantly reduced the risk of structural failure or tip-over incidents.

Power, Control, And Lifecycle Performance

Powertrain choice, hydraulic architecture, and control strategy defined scissor lift productivity and total cost of ownership. Industrial users compared electric slab units, rough‑terrain diesels, and emerging high-capacity electric RT platforms against duty cycle, emissions limits, and site conditions. Lifecycle performance also depended on safety electronics, telematics, and how well maintenance regimes matched OEM recommendations. This section focused on quantifying those trade-offs so specifiers could align lift selection with operational and regulatory constraints.

Electric Vs. Diesel: Duty Cycle And Emissions

Electric scissor lifts used battery packs, typically deep-cycle lead-acid or increasingly lithium-ion, to deliver zero local exhaust emissions. JCB electric units, for example, operated on deep-cycle lead-acid batteries that required about eight hours to reach full charge and then supported a full typical shift. These machines suited indoor or low-emission outdoor tasks where ventilation limits combustion engines or where noise limits applied. Diesel and rough-terrain models, such as Haulotte Compact 3368 RT or HS-series platforms, offered higher ground clearance, larger tires, and higher lift capacities up to about 750 kilograms for heavy outdoor work. Specifiers evaluated duty cycle by comparing cycle counts per charge or per fuel tank, the expected number of lifts or drive hours per shift, and the availability of charging or refueling infrastructure.

Hydraulic Systems, Speeds, And Energy Efficiency

Industrial and mobile scissor lifts both relied on hydraulic cylinders to raise stacked scissor arms, but power sources differed. Fixed industrial tables used three-phase AC power to drive hydraulic power units, while mobile access platforms used battery-powered electric motors or diesel-driven pumps. Lift speed and lowering speed affected productivity and energy use; manufacturers typically optimized valve sizing and pump displacement to balance cycle time with current draw or fuel burn. High-capacity models, such as Haulotte HS-series units rated around 750 kilograms, required larger cylinders and higher flow, which increased pump power requirements and battery or fuel consumption. Energy-efficient designs minimized throttling losses through proportional valves, used regenerative lowering where feasible, and matched pump duty to expected cycle profiles to reduce heat generation and extend hydraulic component life.

Safety Functions, Sensors, And Control Layouts

Modern scissor lifts integrated multiple redundant safety systems to maintain stability and protect operators. Standard features included dual holding brakes, overload sensing, and tilt sensors that inhibited lift or drive when slope or load exceeded limits. Wind ratings governed outdoor work; typical electric slab lifts were limited to indoor use or low wind, while outdoor-rated units such as several JCB S-series and Haulotte rough-terrain models allowed operation within specified wind speeds, often below 12.5 meters per second. Control layouts followed consistent patterns: a ground control station and a platform control box with key switch, emergency stop, lift/drive selector, proportional joystick, steer rocker, horn, and battery status indication, as seen on Skyjack units. Audible alarms, flashing beacons, and pothole protection devices engaged during elevation to maintain clearance and warn nearby personnel.

Maintenance, Telematics, And Service Life Costs

Lifecycle performance depended heavily on structured maintenance and monitoring. Daily inspections typically covered hydraulic fluid levels, evidence of leaks, tire condition, guardrails, placards, and functional tests of emergency stops and limit switches. Annual inspections, required under standards aligned with OSHA mobile scaffold classifications, verified structural integrity, welds, cylinders, hoses, and control logic. Battery maintenance influenced electric lift costs; lead-acid packs required correct charging profiles and avoidance of chronic undercharge to reach typical service lives, often delivering around 10–15 years of machine life under moderate duty. Telematics platforms, such as JCB LiveLink and similar systems from other OEMs, provided remote usage tracking, fault codes, and geolocation, enabling predictive maintenance and optimized fleet utilization. When evaluating total cost of ownership, engineers considered energy or fuel costs, battery or engine overhauls, hydraulic service intervals, and downtime risk alongside purchase price.

Summary: Matching Lift Specs To Your Application

Industrial scissor lift selection required a structured comparison of height, capacity, power source, and environment. Platform height and working height defined reach, while footprint and floor loading governed integration with existing facilities. Load capacity and machine weight influenced both productivity and structural requirements, including slab design and door or freight elevator constraints. Powertrain choice, hydraulic efficiency, and control architecture determined duty cycle, emissions profile, and operator productivity over the asset life.

Data from JCB, Haulotte, and other ranges showed platform heights from roughly 6 m to more than 19 m and capacities from 150 kg to 750 kg, with bespoke industrial tables reaching 40 t at lower heights. Indoor electric slab units typically stayed below 10 m platform height with lower wind ratings, while rough-terrain and large-deck models prioritized capacity, multi-person rating, and stability systems. Nameplate limits, wind ratings, and person ratings had to align with OSHA mobile scaffold rules, mandated guardrails, and minimum clearances from overhead power lines.

In practice, engineers matched lifts to tasks by first fixing required working height, then back-calculating platform height and verifying that capacity covered personnel, tools, and materials with margin. They then checked floor loading, doorway and aisle constraints, and whether the application demanded electric, hybrid, or diesel power. Telematics, standardized components, and planned maintenance intervals influenced total cost of ownership, especially in rental-heavy fleets and high-utilization plants. As regulations and low-emission requirements evolved, the trend shifted toward higher-capacity electric and all-terrain platforms with advanced sensors, overload protection, and remote diagnostics, balancing reach and payload against safety and lifecycle cost.