Maximum working height is one of the most misunderstood specs on a scissor platform, yet it directly affects safety, reach, and productivity. This guide explains what is max working height on a scissor lift, how it relates to platform height, and how standards define safe reach. You will also see how engineering limits, load ratings, and wind restrictions cap usable height, and how to choose the right lift for your job. By the end, you will be able to read height charts confidently and match scissor platform lift working height to real-world tasks without compromising safety.

Defining Platform Height, Working Height, And Safety

Platform height vs. maximum working height

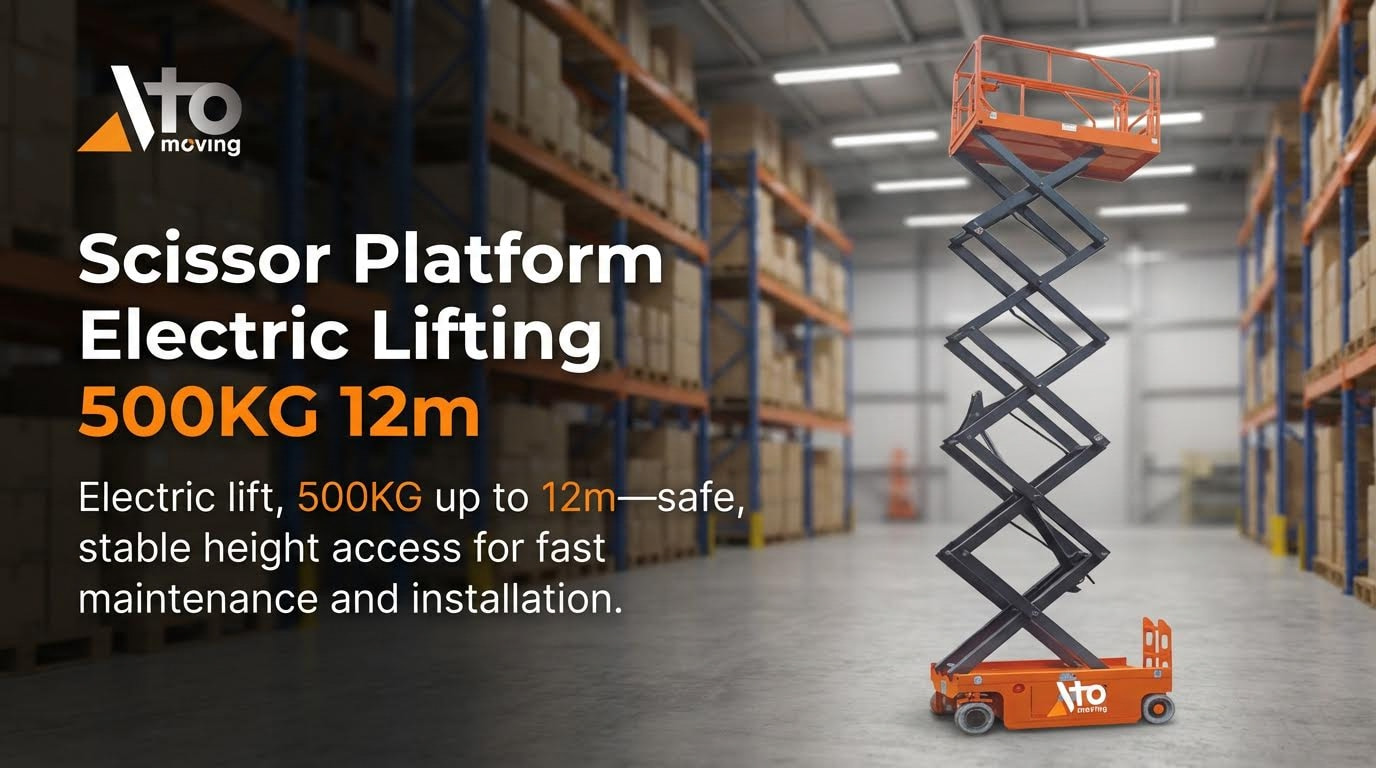

When people ask “what is max working height on a scissor lift,” they often confuse it with platform height. Platform height is the vertical distance from the ground to the floor of the scissor lift platform. Maximum working height is an assumed safe reach above that platform, typically taken as the platform height plus the average person’s vertical reach. In practice, this working height is usually about 1.8–2.0 m (roughly 6 ft) higher than the platform, and manufacturers quote it so planners can match tasks like ceiling work, racking installation, or MEP services to the right machine.

- Platform height: where your feet stand.

- Maximum working height: where your hands can safely work.

- Electric indoor scissor lifts: commonly offer working heights from about 7–14 m.

- Outdoor-rated units: often have slightly lower quoted working heights for the same platform height, due to wind and stability limits.

| Parameter | What it means | Typical use in planning |

|---|---|---|

| Platform height | Ground to platform floor | Clearance to obstacles, access route, door height |

| Maximum working height | Ground to approximate hand level | Can workers safely reach the target work area? |

Always size the machine by the working height you need, but check that the platform height and load rating are compatible with the building and the task.

How standards define safe working reach

Safety standards and regulations treat maximum working height as a controlled, repeatable planning value, not a “stretch as far as you can” number. They assume a typical standing worker, with feet flat on the platform, hands working within a comfortable zone above shoulder level, and guarded by full-height rails. OSHA and similar regulations classify scissor lifts as mobile supported scaffolds, so guardrails, firm level support, and correct positioning are mandatory. These rules limit how far operators may lean or reach beyond the guardrails, which in turn constrains the realistic safe working height.

- Guardrails define the safe envelope; workers must not stand on boxes, rails, or materials to gain extra reach.

- Safe working reach assumes the lift is on level, solid ground with no excessive wind or slope.

- Platform load must stay within the rated capacity, including people, tools, and materials.

- Indoor and outdoor maximum working height ratings can differ for the same model because wind and ground conditions change the stability margin.

Regulators and manufacturers define maximum working height as a planning limit under ideal conditions. If wind, slope, or congestion are present, you may need a lift with greater rated working height to maintain a safe reach.

Why “extra reach” beyond the rating is unsafe

Trying to exceed the rated working height by climbing on objects or leaning hard against the guardrail shifts the center of gravity toward the platform edge. This reduces the stability margin built into the design. In high winds or on uneven floors, that extra reach can combine with dynamic forces from movement, causing the scissor lift to approach its tip or tilt limits. For this reason, safety procedures require operators to choose a lift with sufficient maximum working height for the task instead of improvising extra reach on the platform.

Engineering Limits Behind Maximum Working Height

Stability, center of gravity, and tilt limits

When people ask what is max working height on a scissor lift, the real limit usually comes from stability, not just the reach of the mechanism. As the platform rises, the center of gravity moves upward and small tilts create larger overturning moments. Manufacturers therefore set strict tilt limits and integrate sensors that lock out elevation when the chassis is not level. Typical design controls focus on:

- Keeping the center of gravity well inside the wheelbase at all rated heights

- Limiting maximum slope/grade for driving and elevating

- Using wide outriggers or a larger wheelbase on higher‑reach or rough‑terrain units

Never elevate a scissor platform lift unless it is on firm, level ground and within the manufacturer’s stated grade and tilt limits.

Tilt sensors commonly trigger alarms and disable lift functions when the chassis exceeds a small angle range. This prevents operators from raising the platform into a configuration where a side load, wind gust, or sudden movement could cause a tip‑over. Ground clearance and tire contact pressure also influence stability, especially on uneven or soft surfaces, so higher‑reach models often use heavier frames and larger tires to keep the system stable at maximum working height.

Load ratings, occupants, and dynamic forces

Platform load rating is another hard limit that defines what is max working height on a scissor platform lift in real‑world use. Electric scissor lifts for work at height typically support one to two occupants plus tools, within a rated capacity range. Overloading increases stress on the scissor arms, pins, and hydraulic system, and it also raises the combined center of gravity, reducing stability. Key engineering considerations include:

- Maximum rated load (people, tools, and materials combined)

- Maximum number of occupants allowed

- Load distribution rules (centered vs. edge or side loading)

- Dynamic effects from walking, drilling, or moving materials

| Parameter | Typical Design Focus |

|---|---|

| Rated capacity | Supports expected workers + tools with safety margin |

| Occupants | Usually 1–2, sometimes more on larger platforms |

| Dynamic loads | Allow for movement, impact, and tool vibration |

Dynamic forces can momentarily exceed static loads when workers shift position, handle heavy components, or operate power tools. To manage this, standards and manufacturers apply safety factors to structural design and clearly state limits on partial loading along the platform length and width. Industrial scissor platforms built for freight use much higher capacities and different duty cycles, but even there, rules on even load distribution and maximum overhang are critical to prevent structural damage or loss of stability.

Indoor vs. outdoor ratings and wind restrictions

Maximum working height is also tied to whether the lift is rated for indoor, outdoor, or dual use. Indoors, wind is negligible, so manufacturers can allow greater heights for the same base width and weight. Outdoors, even moderate wind speeds generate side loads on the guardrails, platform, and any sheet materials carried, which can push the machine toward its tipping limit. For this reason, outdoor ratings are usually lower than indoor ratings for the same model.

- Indoor rating: Often allows the full structural working height of the lift

- Outdoor rating: Reduced working height to account for wind and uneven ground

- Wind limit: Maximum allowable wind speed before elevation is prohibited

| Use Case | Typical Limiting Factors |

|---|---|

| Indoor work | Floor capacity, overhead clearance, load rating |

| Outdoor work | Wind speed, ground conditions, reduced working height |

Outdoor‑rated scissor lifts must not be elevated in winds above the manufacturer’s stated limit, even if the platform height is within the rated range.

Regulatory guidance and incident history have shown that high winds can topple elevated platforms, especially when they are driven or repositioned while raised. As a result, many machines are restricted from traveling at height, and operators must lower the platform before moving in exposed outdoor conditions. When deciding what is max working height on a aerial platform for a specific job, you must always apply the lower of the indoor/outdoor rating, the wind restriction, and the load and tilt limits given in the operator’s manual.

Selecting The Right Working Height For Your Job

Matching working height to task and environment

When planning any job, start by asking not only “what is max working height on a scissor lift?” but “what height do we actually need with a margin for safety?”. Working height is usually estimated as platform height plus the average operator reach, but you must also consider obstacles, access routes, and floor conditions. For indoor work, compact electric scissor lifts with moderate working height are often enough, while outdoor jobs may need extra height plus higher stability. Always check the manufacturer’s data plate for maximum working height, platform capacity, and whether the rating is indoor-only or indoor/outdoor.

- Define the task: ceiling work, racking, façade, MEP installation, signage, etc.

- Measure the highest work point and add a safety buffer for reach and body position.

- Confirm if the floor is flat, firm, and rated for the machine’s wheel and floor load.

- Check ventilation and emissions limits if considering an engine-powered unit indoors.

Never select a lift on height alone. Capacity, ground conditions, and wind rating are just as critical as maximum working height.

Practical height-matching examples

For warehouse picking or light maintenance, low to mid-height electric scissors are usually sufficient and easier to maneuver in narrow aisles. For exterior cladding or structural work, you may need higher working heights and rough-terrain capability, even if that means using a larger machine than the bare height calculation suggests.

Electric vs. rough‑terrain scissor lifts by height band

Different height bands suit different powertrains and environments, so you should match the machine type as carefully as you match the working height. Electric scissor lifts typically cover low to mid working heights and are optimized for smooth floors and tight spaces. Rough‑terrain diesel or hybrid scissors cover similar and higher working heights but add ground clearance, larger tires, and higher gradability for uneven ground. When asking “what is max working height on a scissor platform lift?” also ask whether that height is available in an electric indoor model, a rough‑terrain outdoor model, or both.

| Typical use band | Common environment | Preferred lift type | Key selection factors |

|---|---|---|---|

| Low height (access just above head height) | Warehouses, retail, light maintenance | Compact electric scissor | Narrow aisles, low floor loads, quiet and zero emissions |

| Medium height (typical indoor ceilings) | Factories, malls, logistics hubs | Standard electric scissor | Working height range, platform capacity, turning radius |

| Medium–high height (multi‑story work) | Outdoor construction, structural steel, façades | Rough‑terrain scissor | Wind rating, gradeability, ground clearance, 4×4 |

- Choose electric when you need low noise, no exhaust, and tight maneuvering on flat floors.

- Choose rough‑terrain when you need higher capacity, better traction, and stability on uneven or sloped ground.

- Always compare indoor vs outdoor maximum working height ratings; some units are de‑rated outside due to wind limits.

When to step up to a higher height band

If your work point is close to the top of a model’s rated working height, consider the next height band. This gives more room for safe body positioning, tool handling, and allows for minor site changes such as added ceiling services or temporary structures that reduce clearance.

Key Takeaways On Scissor Lift Working Heights

Maximum working height is not a guess; it is a planned, engineered limit that protects people at height. Platform height, worker reach, and guardrail design set the basic geometry. Stability, load rating, and wind then decide how much of that reach you can safely use in the real world. When any of these factors change, the safe working height changes with them.

Engineering controls such as wide bases, tilt sensors, and strict capacity limits keep the center of gravity inside a safe zone. Standards then turn these limits into clear rules on leaning, loading, and indoor versus outdoor use. If you push beyond those rules, you eat into the safety margin that prevents tip‑over and structural failure.

For operations and engineering teams, the best practice is simple. Always size the lift by required working height plus a buffer, then confirm platform height, capacity, indoor/outdoor rating, tilt limits, and wind limits on the data plate and in the manual. Choose electric or rough-terrain models to match the floor, slope, and environment. When in doubt, step up to the next height band rather than reaching for “just enough.” That approach keeps work efficient, compliant, and safe.

,

Frequently Asked Questions

What is the maximum working height of a scissor lift?

The maximum working height of a scissor lift typically ranges from 6 meters to 18 meters, depending on the model and manufacturer. Most standard scissor lifts used in indoor or outdoor construction and maintenance have a working height between 6 to 12 meters. Heavy-duty models can reach up to 18 meters for more specialized tasks.

- Indoor scissor lifts usually max out around 10 meters.

- Rough-terrain scissor lifts can extend up to 18 meters for outdoor use.

What factors determine the working height of a scissor lift?

Several factors influence the working height of a scissor lift:

- Platform Design: Larger platforms may limit height due to stability concerns.

- Weight Capacity: Lifts designed to carry heavier loads might sacrifice height.

- Terrain: Rough-terrain models are built taller but sturdier for stability outdoors.

- Regulations: Safety standards like OSHA and ANSI dictate maximum heights based on equipment design. OSHA Guidelines.