Scissor lift safety depended heavily on engineering controls, disciplined operating practices, and rigorous site planning. This article examined how design features, load management, and maintenance strategies reduced tipping and collapse risks. It also covered terrain and slope assessment, weather and environmental limits, and the use of digital tools for monitoring and control. The goal was to give plants and sites a practical, engineering-led framework for safe scissor lift deployment across varied conditions.

Engineering Controls For Scissor Lift Stability

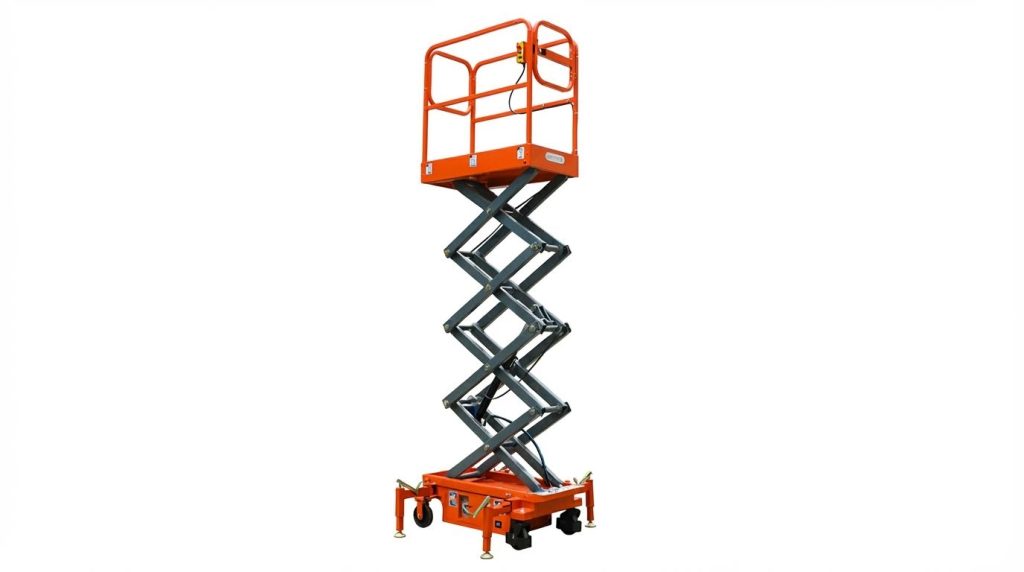

Engineering controls for scissor lift stability transformed generic mobile platforms into engineered mobile elevating work platforms with quantified risk envelopes. Designers used structural mechanics, control systems, and standards such as ANSI A92.20 to define safe operating domains for tipping, structural failure, and hydraulic collapse. This section focused on how center of gravity, platform loading, support systems, and maintenance regimes interacted to determine real-world stability margins across varying sites, slopes, and weather.

Center Of Gravity, Load Charts, And Dynamic Loads

Center of gravity (CoG) position governed scissor lift tipping resistance in both longitudinal and lateral directions. Manufacturers generated load charts by calculating the combined CoG of chassis, structure, and rated payload at different platform heights and outreach conditions, then applying stability factors required by standards. These charts assumed level, firm support and quasi-static loading; they did not fully cover abrupt braking, steering, or worker movement. Dynamic loads from walking, material handling, or wind-induced sway shifted the effective CoG toward stability limits and reduced safety margins. Engineering controls therefore included speed limiting at height, controlled acceleration and deceleration, and interlocks that prevented operation outside defined envelope conditions derived from the load charts.

Platform Loading, Extension Decks, And Moment Control

Platform loading affected not only gross weight but also overturning moment about the chassis support polygon. Concentrated loads at guardrails or on extension decks increased the horizontal distance between the resultant load and the chassis centerline, raising tipping moment even when total mass stayed within the rated capacity. Extension decks reduced stability because they acted as moment arms; manufacturers therefore specified reduced capacities when decks were extended and sometimes prohibited use in higher wind classes. Engineering controls included clearly marked load zones, integrated load-sensing systems, and alarms or cutouts when measured platform load or calculated moment exceeded thresholds. Good practice required operators to distribute tools and materials evenly, secure them against movement, and avoid dynamic actions such as jumping or forceful manual handling that could induce transient moments near the design limits.

Outriggers, Stabilizers, And Chassis Design

Outriggers and stabilizers increased the effective base width and length, improving the ratio of restoring to overturning moments on uneven or sloped ground. Their design considered soil bearing capacity, pad area, and allowable contact pressure to prevent local ground failure that could mimic a tipping event. Interlocks typically required outriggers to reach predefined positions and pressures before allowing elevation, and standards required brakes to be set and, when appropriate, wheel chocks installed. Chassis design also contributed to stability through low-mounted components, wide track widths, and in some models track drives that reduced ground pressure and improved traction on slopes. Engineers used finite element analysis and physical testing to validate that structural deflections under rated loads did not significantly shift CoG or degrade stability, and they defined strict limits on driving with the platform elevated based on these analyses.

Predictive Maintenance For Structural And Hydraulic Integrity

Predictive maintenance protected stability by preventing structural or hydraulic failures that could cause sudden descent, uneven lift, or collapse. Engineers monitored parameters such as cycle counts, pressure profiles, oil temperature, and leak rates to estimate remaining life of pins, bushings, cylinders, and weldments. Non-destructive testing at defined intervals identified fatigue cracks in scissor arms, hinge points, and chassis welds before they propagated to critical size. Condition-based replacement of hoses and seals reduced the risk of asymmetric cylinder performance, which could tilt the platform and shift the CoG unexpectedly. Integrated diagnostics and telematics allowed fleets to track fault codes, abnormal duty cycles, and overload events, feeding reliability models that refined inspection intervals and component redesigns, while ensuring that units with emerging instability risks were locked out and repaired before returning to service.

Terrain, Slopes, And Ground Conditions Risk Management

Terrain and ground conditions governed the real stability envelope of scissor lifts in industrial and construction settings. Engineering-based assessment of soil bearing, slope, and surface capacity reduced tip-over risk beyond what operator skill alone could achieve.

Site Assessment: Soil Bearing, Slopes, And Surface Capacity

A structured site assessment process evaluated soil bearing capacity, surface stiffness, and slope before positioning a scissor lift. Engineers or competent persons identified soft ground, voids, trenches, utility backfill, and uncompacted fill that could collapse under wheel or outrigger loads. Good practice required comparing expected ground contact pressure from wheels or tracks with documented soil bearing values, applying a conservative safety factor of at least 2.0. Operators verified that the support surface was level within the manufacturer’s specified tolerance and free of curbs, holes, and unprotected edges that could induce sudden differential settlement. Where bearing capacity was uncertain, they used spreader mats or steel plates sized to keep contact pressure below allowable limits and reassessed deflection under static pre-load before elevating. Documented slope gradients, measured with a digital level, informed whether the location complied with the machine’s maximum allowable inclination for both travel and elevation.

Operating On Slopes: Ratings, Orientation, And Travel Limits

Manufacturers specified maximum longitudinal and lateral slope ratings, typically in degrees or percent grade, for both driving and elevating. Exceeding these ratings significantly increased the likelihood of tip-over, especially when the platform was raised or extension decks were deployed. Safe practice required traveling straight up or down slopes rather than diagonally, with the designated counterweight or heavy end facing uphill to maintain a favorable center of gravity. Operators engaged brakes and, where allowed, wheel chocks before elevating on slight inclines, and never drove with the platform raised unless the manual explicitly permitted it. When outriggers or stabilizers were available, crews deployed them only on firm, level ground, ensuring that braked wheels lifted last to avoid uncontrolled downslope movement. Travel speeds on inclines remained low, and sharp steering inputs were avoided to limit lateral acceleration and dynamic load transfer. Before each shift, operators confirmed that the planned route complied with rated slope limits, including transition points such as ramps, dock plates, and changes from concrete to gravel.

Collision Avoidance And Traffic Separation Strategies

Collision risk on uneven terrain compounded stability hazards because lateral impacts could push a scissor lift beyond its tipping line. Engineering controls therefore emphasized physical separation from mobile equipment, using barriers, cones, and exclusion zones sized to account for stopping distances and turning radii. Site layouts routed forklifts, trucks, and loaders away from lift operating envelopes, especially near edges, ramps, and congested work fronts. Operators set brakes and used wheel chocks where appropriate, then established visual warnings such as signage and high-visibility tape to alert pedestrians and drivers to the lift’s presence. Procedures prohibited driving under overhead obstacles or near fixed structures without a spotter, reducing the chance of snagging guardrails or platforms. Pre-job briefings addressed traffic patterns, one-way systems, and designated crossing points so that all parties understood right-of-way rules around elevated platforms.

Digital Tools: Inclinometers, Telematics, And Digital Twins

Digital tools enhanced terrain risk management by providing continuous, objective measurements of slope, motion, and usage. Integrated electronic inclinometers or tilt sensors monitored chassis angle and triggered alarms or automatic interlocks when operators approached rated limits. Telematics systems recorded parameters such as travel on slopes, platform height versus wind conditions, and near-tilt events, enabling safety engineers to analyze patterns and refine site rules. Some fleets used geofencing to restrict lift operation in high-risk zones, such as steep ramps or areas with low ground capacity. Emerging digital twin approaches modeled site topography, soil conditions, and equipment characteristics to simulate lift behavior before mobilization, supporting safer positioning and route planning. Combining these tools with disciplined pre-use inspections and operator training created a closed feedback loop that continuously improved terrain-related controls.

Weather, Wind, And Environmental Operating Limits

Weather-driven loads and environmental conditions significantly affected scissor lift stability and component reliability. Engineering limits for wind, precipitation, and temperature defined the safe operating envelope for each model. These limits appeared in the manufacturer’s manual, on data plates, and in ANSI A92.20 compliant documentation. Plants and sites needed procedures that converted these technical limits into clear go / no-go rules for supervisors and operators.

Wind Ratings, Gusts, And Elevated Platform Behavior

Manufacturers specified maximum allowable wind speeds for each scissor lift, typically 12.5 m/s to about 12.8 m/s (25–28 mph) for outdoor-rated units. This rating assumed correct platform loading, guardrails intact, and no unauthorized attachments that increased sail area. At height, wind speed often exceeded ground measurements, so safety plans required either mast-top anemometers or conservative derating factors when only ground readings were available. Operators had to treat gusts, not just average wind, as the governing condition because short-duration gusts could generate overturning moments exceeding design assumptions.

Elevated platforms behaved like flexible cantilevered structures under wind loading. Crosswinds produced sway, dynamic amplification, and increased lateral deflection at the guardrail level. Extended decks and large sheet materials on the platform increased exposed area and shifted the effective center of pressure, reducing stability margins. Engineering controls therefore prohibited using the lift as a support for tarps, signage, or panels that acted as sails. Site rules also restricted travel with the platform elevated in windy conditions unless explicitly allowed and within the manufacturer’s specified travel-wind envelope.

Rain, Cold, Heat, And Their Effects On Systems And Workers

Rain reduced tire–ground friction, softened unpaved soils, and increased slip risk on the platform deck. Electric scissor lifts were not designed as fully waterproof systems; standards and manuals required avoiding operation in open rain unless the model carried a suitable outdoor rating and electrical protection measures were in place. Hydraulic systems exposed to mud and water needed prompt cleaning and drying to prevent contamination, corrosion, and seal degradation. Engineering procedures required reassessing ground bearing capacity after heavy rain and suspending work if ponding, rutting, or surface pumping appeared.

Cold environments affected both equipment and personnel. Hydraulic oil viscosity increased at low temperatures, slowing response and stressing pumps and valves, while batteries delivered reduced capacity. Below roughly 10 °C, sites implemented cold-weather start-up procedures, including warm-up cycles and fluid checks, and below about 10 °C to 0 °C they evaluated risks of ice formation on platforms, access points, and ground. For workers, temperatures below about 10 °C down to freezing introduced frostbite and non-freezing cold injury risks, so PPE, shift rotation, and warm shelters formed part of the lift work plan.

High heat introduced different constraints. At ambient temperatures above roughly 32–35 °C, OSHA guidance treated heat stress as a primary hazard, especially on reflective roofs and paved yards. Operators needed shaded rest breaks, hydration plans, and acclimatization, and supervisors monitored for heat cramps, exhaustion, or stroke. From an engineering standpoint, high temperatures affected battery life, electronic components, and hydraulic cooling margins; operators had to follow derating instructions where manuals specified reduced duty cycles or rest periods in hot weather.

Outdoor Electrical And Hydraulic Protection Measures

Outdoor operation required robust protection of electrical and hydraulic subsystems. Enclosures, cable glands, and connectors needed ingress protection ratings consistent with the expected environment, typically at least IP54 for splashing water, with higher ratings for washdown conditions. When lifts operated near temporary pumping stations or external power feeds, plants installed covers, drip shields, and routing that prevented water ingress and mechanical damage to cables. Electrical isolation procedures ensured that shore power or charging connections were disconnected and stowed before travel or elevation.

Hydraulic circuits required protection from contamination, impact, and temperature extremes. Engineers specified hose routing away from pinch points, wheel paths, and sharp edges, and they mandated abrasion sleeves or guards in exposed zones. After exposure to mud or cementitious materials, maintenance teams cleaned cylinder rods and scissor linkages</a

Summary And Implementation Guidance For Plants And Sites

Engineering a safe scissor lift program required an integrated approach that addressed stability, terrain, and weather as coupled hazards. Plants and sites that reduced incidents combined design-stage controls, rigorous pre-use inspections, and clear operating envelopes for slopes and wind. They used load charts, center-of-gravity management, and chassis or outrigger configuration to keep platforms within rated stability margins. They also embedded predictive maintenance for structural and hydraulic systems to prevent collapses and loss-of-control events.

From an industry perspective, sites that treated scissor lifts as mobile elevating work platforms under modern MEWP standards aligned best with OSHA and ANSI A92.20 requirements. They formalized site assessment for soil bearing capacity, surface load ratings, and traffic separation, rather than leaving placement to operator judgment alone. Weather policies set explicit wind, temperature, and precipitation limits, and they required shutdown when conditions exceeded manufacturer specifications. Emerging tools such as telematics, digital inclinometers, and digital twins supported data-driven decisions about utilization, near-miss analysis, and compliance tracking.

For practical implementation, facilities should codify a lift safety standard that covers equipment selection, terrain criteria, slope and travel rules, and environmental limits in one controlled document. That standard should reference manufacturer manuals, OSHA guidance, and internal risk tolerances, and it should define approval workflows for exceptions. Training programs must link theory to the site’s actual lift models, ground conditions, and typical weather patterns, backed by periodic drills on emergency descent and rescue. Management should track KPIs such as pre-use inspection completion, wind-limit violations, and tip-over precursors to drive continuous improvement.

Looking ahead, scissor lift safety will continue to evolve toward more automation and analytics rather than relying only on operator vigilance. Expect wider adoption of interlocks that prevent elevation beyond rated wind or slope, on-board load sensing with alarms, and geo-fenced travel limits around drop-offs or weak surfaces. However, even with advanced controls, plants and sites will still need disciplined engineering reviews, conservative operating envelopes, and a safety culture that allows operators to stop work when conditions degrade. Balancing technological safeguards with robust procedures and competent people will remain the most reliable defense against tipping, weather, and terrain-related incidents.