Scissor lift fall protection required a precise understanding of how OSHA classified these machines and which standards applied. This article outlined the regulatory framework, including OSHA scaffold and aerial lift rules and ANSI MEWP requirements, and linked them to employer duties and documentation practices. It then explained when guardrails alone were acceptable, when personal fall arrest or restraint systems became mandatory, and how manufacturer instructions interacted with OSHA minimums and common field misconceptions. Finally, it translated these rules into engineering best practices for harness and anchorage selection, PFAS design, inspection programs, traffic control, and a practical compliance checklist for day‑to‑day operations.

Regulatory Framework For Scissor Lift Fall Safety

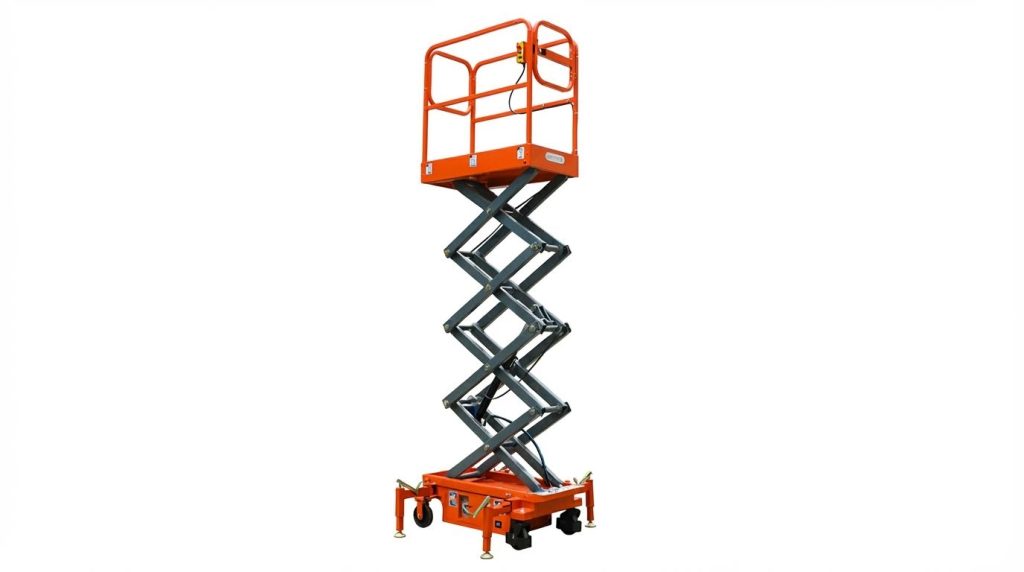

The regulatory framework for scissor lifts fall safety treated scissor lifts primarily as mobile scaffolds rather than aerial lifts under OSHA. This classification drove which fall protection rules applied and when personal fall protection systems were mandatory. ANSI MEWP standards then added design and training requirements that complemented OSHA’s performance-based rules. Employers had to integrate all of these sources into a coherent written program, backed by documented training and inspections.

Scissor Lifts As Mobile Scaffolds Under OSHA

OSHA classified scissor lifts as mobile scaffolds, not aerial lifts, for most regulatory purposes. As a result, scaffold fall protection requirements in 29 CFR 1926.451(g) applied instead of aerial lift rules in 1926.453. Guardrail systems that met OSHA height and strength criteria were considered adequate fall protection in typical warehouse and industrial environments. However, OSHA expected personal fall protection when guardrails were missing, incomplete, or when workers created additional fall exposure by climbing or leaning out. This framework explained why harnesses were not universally mandated on scissor lifts, unlike boom-type aerial lifts.

Key OSHA Standards: 1910.67, 1926.451, 1926.453

Standard 1926.451 governed scaffolds, including mobile scaffolds such as scissor lifts used in construction. Section 1926.451(g)(1) required fall protection on scaffolds at prescribed heights, typically via guardrails or personal fall protection systems. Standard 1910.67 and 1926.453 addressed vehicle-mounted and boom-type aerial lifts, where OSHA mandated personal fall arrest or restraint systems tied off to the boom or basket. In general industry, 1910.67(c)(1)(v) required workers in aerial lifts to wear and attach a fall protection system to the lift structure. In construction, 1926.453(b)(1)(v) historically referenced body belts and lanyards, but body belts were no longer acceptable as part of a personal fall arrest system after 1 January 1998, so full-body harnesses became the norm.

ANSI A92.22 And A92.24 MEWP Requirements

ANSI A92.22 and A92.24 defined modern requirements for Mobile Elevating Work Platforms (MEWPs), including scissor lifts. A92.22 focused on safe use, covering risk assessment, traffic control, and fall protection planning at the site level. A92.24 addressed training, detailing required operator, supervisor, and familiarization training content and verification of competency. These ANSI standards went beyond OSHA’s minimums by structuring how employers should plan, train, and document MEWP operations. Manufacturers aligned their manuals and decals with A92 requirements, which meant employer compliance with manufacturer instructions effectively supported ANSI conformance.

Employer Legal Duties And Documentation

Employers had a legal duty under OSHA to provide a workplace free from recognized fall hazards, including those associated with scissor lifts. They had to ensure that appropriate fall protection, whether guardrails or personal fall protection systems, was available, correctly used, and maintained. Regulations required employers to train and authorize scissor lift operators, verify their competency, and retain records of initial and refresher training. Employers also needed documented procedures for inspections, hazard assessments, and traffic management around lifts. When manufacturer guidance or internal policies exceeded OSHA minimums, those requirements became enforceable employer rules, and documentation served as critical evidence of due diligence during audits or incident investigations.

When Harnesses Are Required On Scissor Lifts

Harness use on scissor lifts depended on a combination of OSHA rules, ANSI MEWP standards, and manufacturer instructions. Guardrails served as the default fall protection, but additional personal fall protection became mandatory when guardrail integrity or worker behavior introduced extra fall hazards. Employers therefore needed a clear decision framework that linked site conditions, equipment configuration, and regulatory requirements into a consistent policy. This section explained when guardrails alone were acceptable and when a Personal Fall Arrest System (PFAS) or fall restraint system became necessary.

Guardrails As Primary Fall Protection

OSHA classified scissor lifts as mobile scaffolds, so scaffold fall protection rules applied rather than aerial lift rules. Under 29 CFR 1926.451(g)(1), compliant guardrail systems provided primary fall protection when intact and at the correct height. In typical warehouse and industrial applications, a complete guardrail system around the platform met OSHA fall protection expectations without mandatory harness use. Workers had to stand on the platform floor, keep access gates closed, and avoid climbing or leaning over the rails to maintain this protection level. Employers needed to inspect rails before use, repair damage immediately, and clearly label rails that required reinspection or were out of service.

Conditions Triggering PFAS Or Restraint Use

Harnesses became required when guardrails were missing, damaged, removed, or otherwise not fully effective. A PFAS or fall restraint system was also necessary when workers used custom platforms, extensions, or configurations without fully compliant rails. Additional fall protection was required whenever tasks caused workers to lean outside the guardrail envelope, climb on objects, or work with open gates. Employers often mandated PFAS use on scissor lifts when manufacturer instructions, internal policies, or site risk assessments identified elevated hazards. In practice, many facilities required harnesses whenever any type of lift was used to avoid confusion between boom and scissor lift rules.

Manufacturer Instructions Vs. OSHA Minimums

OSHA standards defined minimum legal requirements, but manufacturers frequently specified stricter conditions for fall protection. If the manufacturer manual required a harness or restraint system for particular configurations or heights, employers had to follow those instructions under OSHA’s general duty and training provisions. Some MEWP manufacturers provided dedicated anchorage points and recommended full-body harnesses with lanyards even though OSHA did not universally mandate them for scissor lifts. Machines with design limits on lanyard length effectively required fall restraint rather than fall arrest to control tip-over and ejection risks. A compliant program therefore compared OSHA, ANSI A92.22/A92.24, and the specific manual, then adopted the most conservative requirement as site policy.

Common Misconceptions About Harness Use

A widespread misconception was that scissor lifts never required harnesses because they had guardrails. In reality, OSHA expected personal fall protection whenever guardrails were inadequate, when manufacturers required it, or when workers created extra fall exposure by leaning or climbing. Another misconception was that any harness or lanyard combination was acceptable if worn. In fact, the system had to be appropriate for fall restraint or fall arrest, correctly rated, and anchored to approved points on the lift. Workers also often assumed that fall arrest was always superior to restraint, but properly configured restraint that prevented reaching the edge usually reduced risk more effectively. Finally, some operators believed annual inspections alone were sufficient; standards instead required users to inspect harnesses and lanyards before each use for wear, damage, or deterioration.

Engineering Best Practices For Fall Protection

Engineering best practices for scissor lift fall protection focus on correctly specifying, integrating, and managing personal fall protection equipment with the lift structure. Engineers and safety managers must align harness, lanyard, and anchorage selection with OSHA Subpart M and relevant ANSI A92 MEWP standards. Good practice also requires controlling free-fall distance and arresting forces, while ensuring equipment remains reliable through systematic inspection and maintenance. Finally, effective traffic and communication controls around the lift are essential to prevent secondary incidents such as collisions or tip-overs.

Selecting Harness, Lanyard, And Anchor Systems

Selection of fall protection components starts with defining the intended mode: fall restraint or fall arrest. For scissor lifts, restraint systems are often preferable because they prevent workers from reaching beyond guardrails, reducing ejection and overreach risks. Engineers should specify full-body harnesses that meet ANSI and OSHA criteria, with dorsal D-rings rated for personal fall arrest and appropriate size adjustment for the user population. Lanyards must match the application: fixed-length or adjustable restraint lanyards for short reach, and energy-absorbing lanyards or self-retracting lifelines for arrest, while avoiding excessive total system length.

Anchorage design requires verification that each designated tie-off point can withstand at least 22.2 kilonewtons (5,000 pounds-force) per attached worker, or be designed under a safety factor by a qualified person. On scissor lifts, engineers should prefer manufacturer-provided anchor points that have undergone static pull testing and are clearly labeled for the number of users. The anchor location should minimize swing-fall potential and avoid sharp edges or pinch points along the lanyard path. Where the manufacturer restricts lanyard length, such as a 0.76 metre to 0.8 metre maximum, the design must enforce restraint rather than arrest to avoid destabilizing the platform.

PFAS Design: 5,000 lb Anchorage And 6 ft Free Fall

Designing a Personal Fall Arrest System for use on elevated platforms requires controlling both free-fall distance and deceleration forces. OSHA expected compliant PFAS to limit free fall to 1.8 metres or less and prevent contact with a lower level under 29 CFR 1926.502(d)(16). Engineers should calculate total fall distance by summing free fall, deceleration, harness stretch, body movement, and required safety clearance above the next lower surface. Energy-absorbing lanyards or self-retracting devices should keep arresting forces below 8 kilonewtons on the worker as referenced in fall protection performance guidance.

Anchorage capacity remains a core design parameter. Each anchorage or anchorage connector must support at least 5,000 pounds-force per user, or be designed with an equivalent safety factor under the supervision of a qualified person. On mobile elevating work platforms, anchor points should be located within the platform footprint to reduce overturning moments during a fall event. Where contact with structures or lower levels cannot be fully prevented despite compliant equipment, OSHA historically allowed limited enforcement discretion if employers demonstrated infeasibility and implemented additional precautions such as parking the lift, setting brakes, and fully deploying outriggers.

Inspection, Maintenance, And Lifecycle Management

Effective fall protection depends on systematic inspection and lifecycle control of all components. Workers must perform pre-use checks on harnesses, lanyards, and connectors, looking for cuts, abrasion, UV damage, hardware deformation, corrosion, or missing labels. Supervisors or competent persons should conduct documented periodic inspections at defined intervals, following manufacturer instructions and ANSI guidance. Equipment that shows impact loading, questionable history, or failed inspection must be removed from service immediately and either destroyed or returned to the manufacturer for evaluation.

Lifecycle management includes tracking purchase dates, service history, and retirement criteria for harnesses and lanyards. Many manufacturers specified a maximum service life under normal use, after which replacement is mandatory regardless of condition. Scissor lift owners should integrate fall protection checks into pre-operation inspections, verifying anchor labels, structural integrity, and compatibility between PFAS hardware and lift attachment points. Labeling or color-coded tagging of guardrails and anchor

Practical Summary And Compliance Checklist

Scissor lift fall protection relied on a layered approach that combined compliant guardrails, task‑based harness use, and documented training. OSHA treated scissor lifts as mobile scaffolds, so guardrails meeting 1926.451 requirements generally provided primary fall protection, while PFAS or restraint became mandatory when guardrail integrity or worker behavior introduced additional fall hazards. ANSI A92.22 and A92.24 framed scissor lifts within the broader MEWP category, emphasizing risk assessment, safe-use planning, and operator training as integral engineering controls, not optional add‑ons. Employers had a non‑delegable legal duty to train, evaluate, and document operator competence, maintain equipment per manufacturer instructions, and ensure appropriate fall protection was available, inspected, and correctly used.

From an implementation standpoint, a practical compliance program started with a written scissor lift and MEWP procedure that cross‑referenced OSHA 1910.67, 1926.451, and 1926.453, as well as applicable ANSI A92 standards. A concise field checklist supported daily use: verify surface stability and load limits, inspect guardrails and access gates, confirm harness and lanyard condition when required, and check anchor ratings and tie‑off points. Operators needed clear rules for when to transition from guardrail‑only protection to PFAS or restraint, especially for work involving leaning, reaching, or non‑standard platforms. Traffic management around the lift, including physical barriers, marked exclusion zones, spotters, and communication protocols, reduced collision and ejection risks.

Future developments in MEWP design and fall restraint technology were expected to tighten integration between platforms, anchorages, and smart lanyards that limited free‑fall and swing hazards. However, technology alone could not replace disciplined procedures and supervision. A balanced strategy combined conservative engineering assumptions, strict adherence to manufacturer instructions, and continuous monitoring of OSHA and ANSI updates. Organizations that embedded these practices into routine pre‑use inspections, permits, and toolbox talks achieved higher safety performance while maintaining operational efficiency.