Electric scissor lifts let teams reach height quickly, but misuse creates severe fall, crush, and electrical risks. This guide explains how to use an electric scissor lift safely by combining pre-use inspections, control logic, and disciplined operating habits.

You will see how daily mechanical checks, safety device tests, and site risk assessments prevent tip-overs and failures before work starts. The article then breaks down power-up sequences, modes, and maneuvering rules so operators understand exactly what each control does in real situations.

Later sections link best practices to OSHA and ANSI expectations, including training, authorization, and record-keeping. The conclusion highlights key safety practices and shows how sound engineering and consistent inspections extend equipment life while reducing incidents and downtime.

Pre-Use Inspection And Site Risk Assessment

Pre-use checks are the first control step when planning how to use an electric scissor lift. A structured inspection and a simple risk assessment remove most mechanical and site-related hazards before elevation. This section explains what to inspect on the machine, how to verify safety systems, and how to judge ground, weather, and loading conditions. The same logic supports both daily field work and formal compliance programs.

Daily Mechanical And Structural Checks

Start with a slow walk-around before turning the key. Look for visible damage, corrosion, bent rails, cracked welds, or deformed scissor arms. Check that pins, bolts, and locking clips sit in place and show no obvious wear.

Inspect wheels and tires for cuts, flat spots, or low pressure. Confirm wheel nuts are present and tight. Look under the chassis and around the scissor stack for hydraulic or battery fluid leaks.

Use a short checklist to keep the process consistent: body, structure, hydraulics, and drive. Typical items include:

- Platform floor condition and clean, non-slip surface

- Entry gate closes and latches correctly

- Guardrails straight, secure, and at full height

- Scissor arms free from dents, twists, and contact marks

- Decals, warnings, and capacity plates readable

For electric units, confirm battery charge level, cable integrity, and connector condition. If any defect affects strength, stability, or control, tag the lift out and remove it from service until a competent technician clears it.

Verifying Safety Devices And Emergency Systems

Safety devices decide how to use an electric scissor lift without taking unnecessary risk. Function-test ground and platform controls before loading people or tools. Confirm the key switch works and both emergency stop buttons cut power instantly.

Operate lift up and down from the ground station, then from the platform. Controls must move smoothly and return to neutral when released. Test drive, steering, and braking where the manufacturer allows ground travel tests.

Check critical protection systems:

- Tilt alarm and cut-out within the rated slope limit

- Descent alarm or beeper during lowering

- Overload or load-sense indicators on the platform

- Horn and any required visual warning lights

Locate the emergency lowering device and verify that it operates the platform down under no-load conditions. Make sure the operator and spotter both know its location and sequence. If any safety device fails a test, stop the job, tag the machine, and request maintenance.

Ground Conditions, Slopes, And Weather Limits

Even a perfect lift becomes unsafe on poor ground. Confirm the surface is firm, level, and able to support the combined weight of the lift, people, and tools. Avoid soft soil, gravel, uncompacted fill, pits, or floor openings.

Compare the actual slope with the manufacturer’s maximum allowed grade. If the tilt alarm sounds while stowed, relocate the lift or improve the surface. Do not override or ignore tilt warnings.

Scan above and around the work area. Remove loose debris, stacked materials, or mobile equipment that could strike the lift. Keep clear of drop-offs, ramps, and dock edges.

Weather strongly affects how to use an electric scissor lift outdoors. Follow the wind speed limit in the manual, especially for extended platforms. Stop elevation when winds approach the rated limit, during storms, or when ice or rain reduces traction and visibility. For indoor work, consider airflow from large fans or open doors that may create local gusts.

Load Rating, PPE, And Fall Protection Review

Check the platform capacity plate before loading. The rating covers people, tools, and materials together. Plan the job so the total mass stays below this number with margin.

Distribute weight evenly on the platform. Keep heavy items low and away from the guardrails and scissor stack. Do not use the lift as a crane or material hoist beyond its design.

Review PPE requirements as part of pre-use planning. Typical items include:

- Hard hat and safety footwear

- High-visibility clothing in busy areas

- Eye and hand protection for the specific task

- Approved fall arrest system if the site or standard requires it

Confirm anchor points on the platform are rated and undamaged before clipping in. Instruct workers to keep both feet on the floor and avoid climbing or leaning on guardrails. A short toolbox talk that covers load limits, PPE, and fall rules helps new operators understand how to use an electric scissor lift in line with site procedures and standards.

Understanding Controls, Modes, And Safe Maneuvers

Operators who search how to use an electric scissor lift usually struggle with control logic and safe movements. This section explains how power-up, mode selection, and joystick behavior work together. It links these functions to real hazards like tip-over, crush, and electrical contact. The goal is predictable machine response and disciplined maneuver planning.

Power-Up Sequence, E-Stops, And Mode Selection

A clear start-up routine keeps the lift predictable and safe. Operators should first confirm the emergency stop buttons at both control stations are released. They then turn the key switch to energize the control system and select the correct control station, usually platform controls for work use.

Mode selection is critical. Typical selector positions are lift mode, drive mode, and neutral. The platform should be fully lowered before switching to drive mode. Many manufacturers locked out drive functions above a set height to reduce tip-over risk.

Emergency stop buttons cut power instantly to motion circuits. Operators must test E-Stops during daily function tests. In an emergency, they should hit the nearest E-Stop, stabilize themselves inside the guardrails, and wait until hazards clear. After any E-Stop, they should reset the button, recheck the mode, and confirm no fault alarms before resuming work.

Platform Lift, Drive, And Steering Control Logic

Control logic for lift, drive, and steer must feel intuitive and repeatable. Most electric scissor lifts use a single joystick with mode-dependent behavior. In lift mode, pushing the joystick forward raises the platform, and pulling it back lowers it. In drive mode, the same movement commands forward and reverse travel.

Steering often uses a thumb rocker or twist grip. Small steering inputs reduce side loading on wheels and scissor structures. Speed selectors usually offer slow and fast ranges. Operators should use slow speed for tight areas, turns, and any work near obstacles.

Good practice is to “bump” the joystick for small corrections instead of full deflection. This limits acceleration, reduces sway, and protects fragile loads. Before each shift, operators should perform function tests from ground and platform controls. They verify smooth lift motion, predictable drive response, and automatic return of controls to neutral.

Travel, Positioning, And Spotter Coordination

Safe travel depends on low height, low speed, and clear paths. Operators should keep the platform fully lowered when driving whenever possible. They should scan ahead for holes, ramps, debris, and overhead obstructions. Travel paths should be firm, level, and within the manufacturer’s slope limits.

Fine positioning near work faces requires patience. Operators should approach slowly, stop short, then elevate vertically into place. They must avoid driving close to floor edges, pits, or drop-offs. Near overhead beams, door headers, or ductwork, they should move in very small increments and watch for crush zones.

Spotters add a second set of eyes in high-risk zones. Typical cases include tight aisles, pedestrian areas, and work under pipe racks or low ceilings. Spotters should walk outside the crush zone and use agreed hand signals or radios. The operator must follow the spotter’s directions unless they see a hazard the spotter cannot see. In any doubt, both should stop movement and reassess the path.

Basic Fault Response And Manual Lowering

When something feels wrong, operators must stop motion first. Common issues include no lift, no drive, or warning lights with alarms. Quick checks include confirming the key is on, E-Stops are released, the correct mode is selected, and the platform is within rated load and slope limits. If problems persist, operators should not bypass safety systems.

Every operator should know the machine’s ground controls and manual lowering system. In a power loss or control failure, a trained person on the ground can usually lower the platform using a dedicated valve or switch. The platform crew should stay inside the guardrails and communicate clearly during lowering.

After any fault that needs manual lowering, the lift should be tagged out. Only maintenance personnel should reset or repair it. Recording the fault in inspection or maintenance logs supports root cause analysis and regulatory compliance. This disciplined response keeps small control problems from becoming serious incidents.

Operational Best Practices And Compliance

Operational best practices show workers how to use an electric scissor lift safely during real jobs. This section links daily use with legal duties and engineering limits. It focuses on tip-over control, fall prevention, training, and documentation. Strong habits in these areas cut accident risk and unplanned downtime.

Preventing Tip-Overs, Crush, And Electrical Hazards

Tip-over control starts with stable support. Position the lift on firm, level ground and respect the manufacturer slope limit, often about 5 degrees. Never drive with the platform elevated unless the manual clearly allows it and the floor is flat and clear. Keep loads inside the guardrail plan area and away from the scissor stack to avoid shifting centers of gravity.

Crush and entrapment hazards increase near beams, ceilings, and pipe racks. Move slowly, look up and around, and use a spotter in tight spaces. Maintain safe clearance from fixed structures when raising or traveling. Use the lift’s tilt and overload alarms as hard limits, not suggestions.

Electrical safety is critical when planning how to use an electric scissor lift near live conductors. Maintain at least 3 metres clearance from energized lines unless you are qualified and rules allow closer work. Treat all overhead lines as live. Use non-conductive tools when practical and follow lockout or isolation procedures for in-plant busbars.

Work Practices On The Platform And Guardrails

Safe platform behavior keeps falls rare even when the lift is at full height. Operators and riders must keep both feet on the platform floor and stay inside the guardrails. Do not climb, sit, or stand on rails, boxes, or ladders to gain extra reach. Keep the entry gate or chain fully closed whenever the platform is elevated.

Housekeeping on the platform supports safe movement and clear escape paths. Remove loose debris, coiled cables, and offcut material that create trip hazards. Store tools in belts, bags, or lanyards to prevent dropped objects. Keep materials low and centered, never stacked against the rails.

Good communication habits reduce confusion during complex tasks. Agree on hand signals or radio calls between the platform and spotter before starting work. Pause movement if you lose sight of the spotter or cannot hear instructions. Use the horn before moving in congested areas so nearby workers can react.

Training, Authorization, And Regulatory Duties

Only trained and authorized people should operate an electric scissor lift. Training must cover the specific model, its controls, safety devices, and emergency lowering options. It should also explain typical hazards such as tip-overs, crush points, and electrical contact, and how to avoid them.

From a compliance view, employers must meet OSHA and ANSI style requirements for aerial platforms. That includes formal instruction, hands-on practice, and evaluation of each operator. Refresher training is needed after incidents, near misses, or major equipment changes. Site rules should define who may use the lift, in which areas, and under what conditions.

PPE expectations must be clear and enforced. Typical items include hard hat, safety footwear, high-visibility clothing, and fall protection when required by site policy or regulation. Operators must not work under the influence of alcohol, drugs, or fatigue that affects judgment.

Inspection Records, Tagout, And Maintenance

Written inspection records show that the site runs the lift responsibly and understands how to use an electric scissor lift over its full life cycle. Daily pre-use checks should follow a standard form that covers structure, hydraulics, electrics, controls, and safety devices. Keep these forms or digital records for the period required by local rules or company policy.

Any defect that affects safe operation needs immediate action. Tag the lift out of service with a clear “Do Not Use” label. Remove the key and report the fault to maintenance. Only competent technicians should repair structural parts, hydraulic systems, or control circuits.

Planned maintenance follows the manufacturer schedule based on hours and calendar time. Typical tasks include fluid checks, filter changes, torque checks on pins and bolts, and function tests of alarms and emergency systems. Good maintenance reduces failure rates, supports compliance, and extends asset life while keeping operators safe.

Summary Of Key Safety Practices And Engineering Impacts

Knowing how to use an electric scissor lift safely starts with a fixed routine. Operators inspect the machine, assess the site, and follow strict control rules every shift. The core practices stay the same across models, even as designs change.

Key safety habits include daily mechanical checks, full function tests, and a clear tagout process for defects. Operators work only on firm, level ground and stay within slope and wind limits from the manual. They keep loads inside the rated capacity and within the guardrails. Ground spotters support work in tight or high‑hazard areas.

From an engineering view, these rules protect stability margins, structural life, and control system reliability. Respecting limits on slope, wind, and platform load preserves the safety factors built into the chassis, scissor stack, and brakes. Routine inspections also reduce unexpected failures and downtime.

Future designs will likely add better sensors, smarter tilt and overload logic, and clearer human‑machine interfaces. Digital inspection checklists and telematics will support compliance and fleet health tracking. Still, safe outcomes will depend on trained operators who follow procedures, read the manual, and never bypass safety devices.

Frequently Asked Questions

How to Operate an Electric Scissor Lift Step by Step?

To operate an electric scissor lift, start by ensuring the machine is on a flat, stable surface. Insert the key into the control panel and turn it to power on the device. Next, flip the hydraulic switch to the left to enable the lift’s up-and-down movement. Use the control joystick or buttons to raise and lower the platform as needed. Always follow safety protocols, such as wearing a harness if required. Scissor Lift Operation Guide.

How Does an Electric Scissor Lift Work?

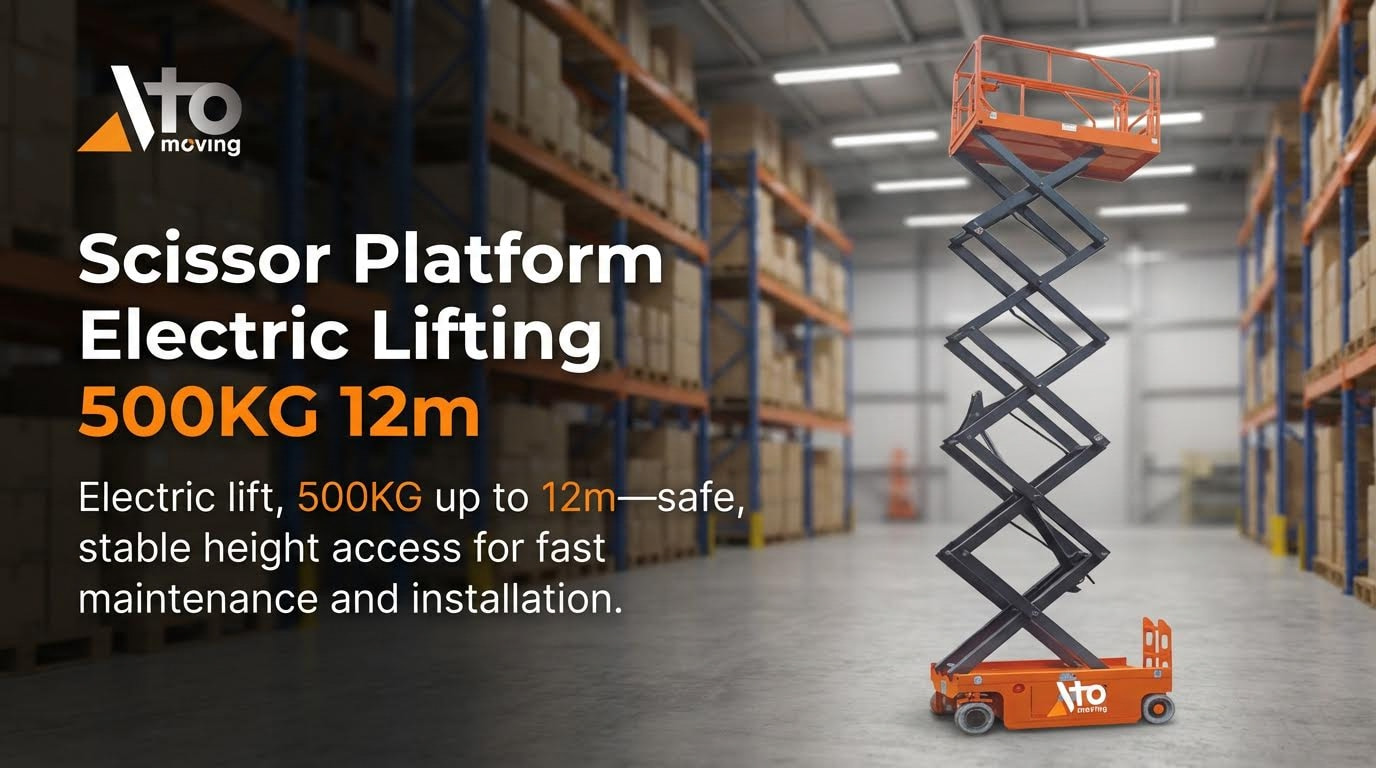

An electric scissor lift operates using a hydraulic or pneumatic system. When powered on, the motor fills the cylinder with hydraulic fluid or compressed air. This pressure pushes the cylinder outward, causing the scissor legs to extend and lift the platform. The process is reversed to lower the platform. These lifts are commonly used for indoor tasks due to their quiet operation and zero emissions. Scissor Lift Working Principle.

What Safety Steps Should You Follow When Using an Electric Scissor Lift?

Always inspect the scissor lift before use to ensure it’s in good condition. Stand clear of the platform while it’s moving, and never exceed the weight capacity. Use the emergency stop button in case of any issues. Avoid operating the lift in uneven or hazardous terrain. Proper training is essential to safely operate the equipment and prevent accidents.