Modern industrial plants handle thousands of drums every year, often under tight safety and productivity targets. This guide explains how to choose drum handling equipment that fits real-world tasks, from low-level moves to automated palletizing and hot melt unloading. You will see how drum sizes, weights, layouts, and OSHA-driven safety rules shape equipment selection and integration.

The full outline walks through core drum handling tasks, equipment types and specifications, and lifecycle economics before closing with strategic buying considerations. It links typical operations such as lifting, pouring, racking, and transport to the right tools, including stackers, palletizers, and high-viscosity drum unloaders. Throughout, the focus stays on safe ergonomics, technical sizing, and cost-justified automation for both manual and automated drum handling systems.

Core Drum Handling Tasks And Use Cases

Core tasks define how to choose drum handling equipment for a plant. Engineers must match drum sizes, weights, and operations with safe, ergonomic tools. This section explains typical load profiles, daily handling cycles, and OSHA-driven practices that shape equipment choices and layouts.

Typical Drum Sizes, Weights, And Load Profiles

Most industrial plants handle 200–220 litre drums, often called 55-gallon drums. A full 55-gallon drum typically weighs 180–360 kilograms depending on contents. Load profiles change with liquid density, fill level, and centre of gravity. Viscous products and slurries create higher dynamic loads during tilting, mixing, or transport. Engineers should define at least:

- Drum volume and material (steel, plastic, fibre)

- Typical and maximum filled weight in kilograms

- Handling orientation (vertical, horizontal, on pallets, in racks)

- Required rotation angle (0–360°) and frequency per shift

These parameters guide safe rated capacities and gripping methods. Undersized devices increase risk of dropped drums and structural failure.

Common Operations: Lift, Pour, Rack, And Transport

Core operations drive how to choose drum handling equipment for each area. Typical tasks include:

| Operation | Key requirement |

|---|---|

| Floor-to-floor transport | Stable rolling or wheeled movement |

| Vertical lifting | Clear height and pallet access |

| Pouring / decanting | Controlled rotation and flow |

| Racking / stacking | Precise placement in racks or on pallets |

Low-level moves often use drum trucks, cradles, or movers with lift heights around 280–500 millimetres. Pallet loading uses straddle designs that pass over standard pallets and reach centre drums. High-lift tasks, such as placing drums into racks at 1,000–3,000 millimetres, use hydraulic drum stackers or palletizers. Decanting viscous materials may require heated unloaders or controlled tilters to reduce splash and ergonomic strain.

Matching Equipment Types To Process Requirements

Process requirements determine which equipment class fits best. Manual drum trucks and movers suit low-throughput zones and short moves with good floor conditions. Manual hydraulic lifters and palletizers bridge the gap when lift height is moderate and budgets are tight. Typical units lift 400–450 kilograms to 300–600 millimetres and rely on hand pumps.

Hydraulic drum stackers handle higher elevations and heavier duty cycles. Typical designs lift to 1,000–3,000 millimetres and weigh about 250 kilograms. Plants with high volume or 24/7 shifts should consider automatic palletizers or robotic cells. These systems integrate weighing, clamping, and stacking in one frame and reduce manual touches. For high-viscosity polymers or adhesives, hot melt drum unloaders heat and pump material directly, avoiding manual pouring.

When deciding how to choose drum handling equipment, compare:

- Required lift height versus rated stroke

- Maximum drum mass versus safe working load

- Drum material compatibility (steel, plastic, fibre)

- Needed automation level versus labour availability

Ergonomics And OSHA-Driven Safety Practices

Ergonomics and OSHA rules strongly influence equipment choice. Manual rolling and upending of 180–360 kilogram drums creates high risk of back and crush injuries. Plants should favour devices that keep operators upright, with neutral wrist and back posture. Pedal or hand-pump hydraulics reduce push and lift forces compared with pure manual handling.

Key safety practices include:

- Read drum labels and Safety Data Sheets before movement

- Treat unlabelled drums as hazardous until identified

- Inspect for leaks, missing bungs, and deformation

- Use non-sparking tools and explosion controls in flammable areas

OSHA-driven programs require proper PPE, fire protection per 29 CFR 1910 Subpart L, and safe distances during drum opening. Controls for opening or cutting equipment should sit behind shields or barriers. Bare forklift forks under drums are unsafe and should be replaced with purpose-built drum attachments or dedicated handlers. Good ergonomic design, combined with compliant procedures, lowers injury rates and supports long-term productivity.

Types Of Drum Handling Equipment And Specs

Engineers who ask how to choose drum handling equipment need a clear view of device types and limits. This section compares low-level movers, high-lift stackers, automatic palletizers, and hot melt drum unloaders. It links typical drum weights and sizes to safe capacities, lift heights, and duty cycles. The goal is to match equipment to process steps without overloading, under‑specifying, or wasting floor space.

Drum Trucks, Cradles, And Movers: Low-Level Handling

Drum trucks, cradles, and movers support short moves at floor level. They suit tasks like unloading delivery trucks, feeding workstations, or repositioning drums in small plants. Typical designs handle standard 210 litre steel or plastic drums and keep lift heights below about 300 millimetres.

When deciding how to choose drum handling equipment for low-level work, engineers usually check three core points:

- Rated capacity versus worst‑case drum mass, including dense liquids.

- Minimum and maximum drum diameters and whether ribs or chimes are needed for grip.

- Wheel and castor type versus floor conditions, slopes, and thresholds.

Mild steel movers often weigh 50–150 kilograms and offer lift heights around 280 millimetres. These units reduce manual push forces and back strain, yet still rely on walking operators. They fit sites with moderate drum volumes and short travel distances. For corrosive or outdoor use, stainless or coated frames reduce degradation and seizure of moving parts.

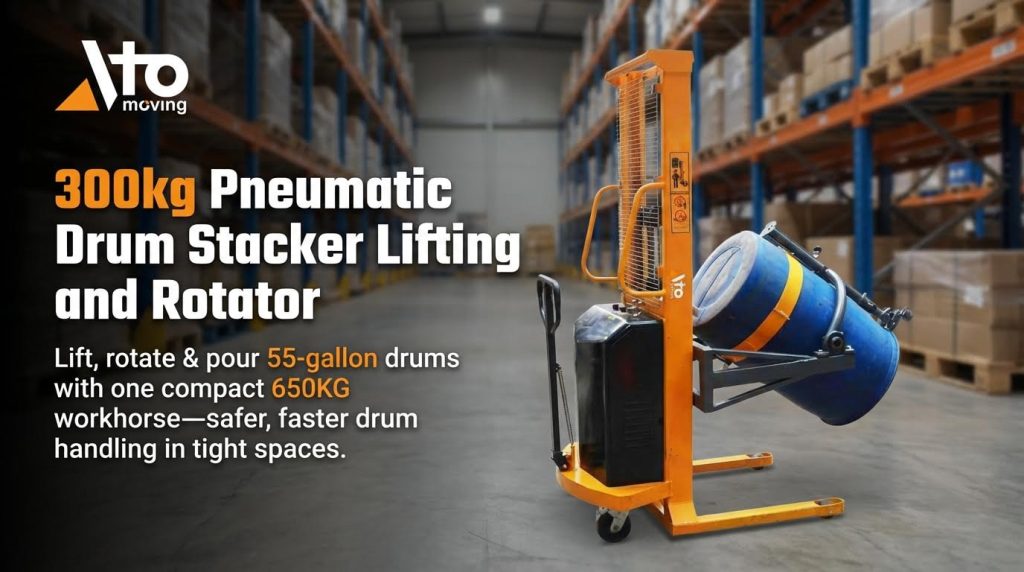

Drum Stackers, Palletizers, And High-Lift Devices

Drum stackers and palletizers raise drums onto pallets, racks, or into trucks. They bridge the gap between floor handling and vertical storage. Manual hydraulic drum stackers often provide lift heights from roughly 1 000 to 3 000 millimetres and handle a single 210 litre drum.

Key selection factors include:

| Parameter | Typical range or option |

|---|---|

| Capacity | About 400–450 kilograms per drum |

| Lift height | 300 millimetres (palletizers) up to 3 000 millimetres (stackers) |

| Power | Manual hydraulic, battery, or mains electric |

| Leg geometry | Straddle legs, C‑frame, or adjustable legs |

Straddle leg pallet loaders can glide over standard pallets and pick drums from the middle or corners. Adjustable leg palletizers help when aisles are narrow or pallets vary. Eagle‑grip or rim‑clamp heads allow handling of steel, plastic, and fibre drums with automatic clamping. When planning how to choose drum handling equipment for racking, engineers must match lift height to rack beam level and verify slab and rack load ratings.

Automatic Drum Palletizers And Robotic Integration

Automatic drum palletizers and robotic cells suit high‑volume filling and shipping lines. They reduce manual touches and improve stacking repeatability. Global palletizing equipment demand grew with the push for higher throughput and lower labour exposure.

When specifying these systems, engineers usually compare:

- Required throughput in drums per hour versus machine speed and uptime.

- Drum range, from small pails to 55 gallon units, and any mix of plastic, steel, and fibre.

- Available footprint and ceiling height for conveyors, guarding, and pallet magazines.

- Integration with upstream fillers and downstream stretch wrappers.

Automatic systems may be fully automatic or semi‑automatic. Fully automatic lines handle drum infeed, pattern forming, and pallet discharge with minimal operator input. Semi‑automatic units still need manual pallet placement or pattern confirmation. Robotic arms add flexibility for changing drum sizes or mixed loads but raise initial cost and programming needs. Safety design must include guarding, interlocks, emergency stops, and sensors around the palletizing zone.

Hot Melt Drum Unloaders For High-Viscosity Materials

Hot melt drum unloaders serve a different role from standard drum movers. They heat and pump highly viscous materials, such as pressure sensitive or polyurethane reactive adhesives, directly from drums into production lines. Typical systems use heated platens that press into 200 litre or similar drums and melt material at controlled rates.

When deciding how to choose drum handling equipment for hot melts, teams focus on process performance rather than simple lift and carry. Important checks include:

- Viscosity and required melt rate in kilograms per hour.

- Need for continuous versus batch operation, which affects single or tandem system choice.

- Maximum operating temperature, sometimes up to about 260 degrees Celsius.

- Required pump type, filtration, and metering accuracy.

Hydraulic rams may need to generate several tonnes of force for very viscous products. Options such as machined platens, position sensors, and automatic bleed or boost functions cut changeover time and improve safety. These systems demand careful cost‑benefit analysis because investments can range from moderate to very high, but gains in throughput, reduced waste, and cleaner operation often justify the spend over the equipment life.

Selection, Integration, And Lifecycle Economics

Engineers who ask how to choose drum handling equipment must balance sizing, layout, safety, and long-term cost. Selection errors often lock plants into bottlenecks, unsafe practices, or hidden lifecycle expense. This section explains how to specify capacity and height, integrate with floors and conveyors, manage hazardous materials, and model lifecycle economics for modern drum systems.

Key Sizing Parameters: Capacity, Height, And Drum Type

Correct sizing starts with drum mass and geometry. A typical 210 litre drum can weigh 180–360 kilograms when full, so equipment capacity should include a safety margin, not just nameplate rating. For example, pallet loaders in the market often support 400–450 kilograms per drum, which suits most steel drums but may be low for dense products.

Lift height depends on target interfaces. Common ranges are:

- 0–300 millimetres for low-level palletizers and movers

- 300–600 millimetres for loading standard pallets or low conveyors

- 1 000–3 000 millimetres for drum stackers and racking

Drum type strongly affects the gripping system. Steel drums tolerate chime grabs and “eagle” clamps. Plastic and fibre drums often need full circumference clamping or cradle support to avoid deformation. When deciding how to choose drum handling equipment, match the clamping method to wall stiffness, chime strength, and any liner system.

Engineers should define a sizing envelope that covers:

- Drum volume range, for example 60–210 litres

- Diameter and height range

- Maximum product density and ambient temperature

- Required tilt or rotation angles for pouring or mixing

This envelope then drives hydraulic cylinder sizing, frame section choice, wheel selection, and stability calculations.

Floor Space, Layout, And Conveyor System Integration

Layout planning often decides which solution wins the project. Narrow aisles favour compact drum trucks or walk-behind stackers with small turning radii. Straddle leg palletizers can bridge standard pallets but need clear fork pockets and floor free of obstructions.

When you plan how to choose drum handling equipment for conveyor lines, check three interfaces:

- Infeed and discharge heights relative to roller or belt tops

- Conveyor frame clearance for legs, wheels, and stabilizers

- Flow direction to avoid reverse or cross-traffic with forklifts

Inline automatic palletizers and robotic cells require defined accumulation zones and guarding periphery. Measure ceiling height, sprinkler clearance, and overhead services before fixing stack heights. Use simple block-layout diagrams to test alternative traffic patterns for drums, pallets, and empty containers.

Floor bearing capacity also matters. Concentrated loads from hydraulic stackers and loaded pallets can exceed light-duty slab ratings. Verify allowable load in kilonewtons per square metre and compare with worst-case pallet plus equipment mass.

Safety, Compliance, And Hazardous Material Handling

Safety and regulations should shape every decision on how to choose drum handling equipment. A full 55 gallon drum can weigh up to about 360 kilograms, so manual handling creates serious injury risk. Equipment should reduce push, pull, and lift forces to levels that align with ergonomic guidelines.

For hazardous, flammable, or toxic contents, selection must support:

- Secure clamping to prevent drops, even with smooth plastic drums

- Controlled tilting and decanting to avoid splashes

- Operation that keeps the operator outside likely spill zones

Plants must also consider OSHA-driven controls and local fire codes. Good practice includes non-sparking tools in flammable zones, explosion-resistant barriers for drum opening, and fire extinguishing systems that comply with industrial standards. Equipment used in classified areas may need antistatic wheels, proper grounding, or certified electrical parts.

Procedures remain as important as hardware. Labels and Safety Data Sheets should guide PPE, ventilation, and emergency response. Training must cover safe rolling, upending, and use of lifter bars, plus clear rules against lifting drums on bare forklift forks.

Lifecycle Cost, Maintenance, And Digital Monitoring

Lifecycle economics go far beyond purchase price. A low-cost manual lifter might suit low-throughput areas, but high-volume lines often justify automatic palletizers or robotic cells through labour savings and fewer injuries. When comparing options, include energy use, planned maintenance, downtime risk, and spare parts support.

Typical cost elements include:

- Acquisition: equipment, installation, guarding, and commissioning

- Operation: labour hours, power, and changeover time

- Maintenance: parts, inspections, and hydraulic service

- Compliance: periodic audits, training, and documentation

Digital monitoring is becoming standard for higher-end drum systems. Sensors can track cycle counts, overload events, and fault codes. Data feeds into predictive maintenance tools that schedule service before failure. For hot melt drum unloaders and complex palletizing cells, this data also supports cost–benefit analysis and throughput optimisation.

Engineers deciding how to choose drum handling equipment should build a simple total cost of ownership model over five to ten years. This model can compare manual, semi-automatic, and automatic solutions and link each option to injury reduction, uptime, and staffing plans.

Summary And Strategic Buying Considerations

Knowing how to choose drum handling equipment requires a structured view of risk, throughput, and lifecycle cost. Modern plants needed to move beyond ad‑hoc purchases and treat drum handling as a core part of the material flow design. The right mix of trucks, stackers, palletizers, and hot melt unloaders depended on drum size, weight, hazard level, and automation targets.

Technical due diligence started with clear load cases. Engineers defined maximum,

Frequently Asked Questions

How do you select material handling equipment?

Selecting the right material handling equipment starts with identifying your specific needs. Assess factors like the size and weight of the drums, the environment where the equipment will be used, and the functionality required. Focus on safety features and ease of use to ensure efficient operations. For more detailed guidance, check this equipment selection guide.

What are the factors to consider in selecting the equipment?

When choosing drum handling equipment, consider these key factors: match the production output with the equipment’s capacity, evaluate training needs, compare prices, and decide between new or used equipment. Also, think about leasing versus buying and the availability of replacement parts. For additional insights, refer to this equipment purchasing checklist.

What should you consider before purchasing equipment?

Prior to purchasing, reflect on the qualities the equipment brings to your business such as reliability, capacity, efficiency, and environmental impact. Maintenance is another crucial factor. These considerations help ensure long-term value and performance. Learn more from this equipment investment advice.

What is a good way to determine your equipment needs?

To determine your equipment needs, evaluate the size and weight requirements, job site conditions, and the skills of your employees. Don’t hesitate to overestimate rental costs and seek expert advice if needed. This approach helps in making informed decisions. Find useful tips in this job equipment guide.