Want to learn the basics of an electric order picker and its impact on warehouses? Today, let’s analyze the functions, trends, and advantages of electric order pickers.

Introduction

In today’s fast-paced warehouses, efficient material handling is not optional, but a necessity. For companies, choosing the right equipment can make or break operations. And the use of electric order pickers plays a key role. This type of warehousing equipment is changing the way companies manage inventory, especially in the context of surging e-commerce and logistics demand. This article will take a closer look at what an electric order picker is, its core functions, and why it is an important investment for companies.

Understanding electric order pickers: analyzing core functions

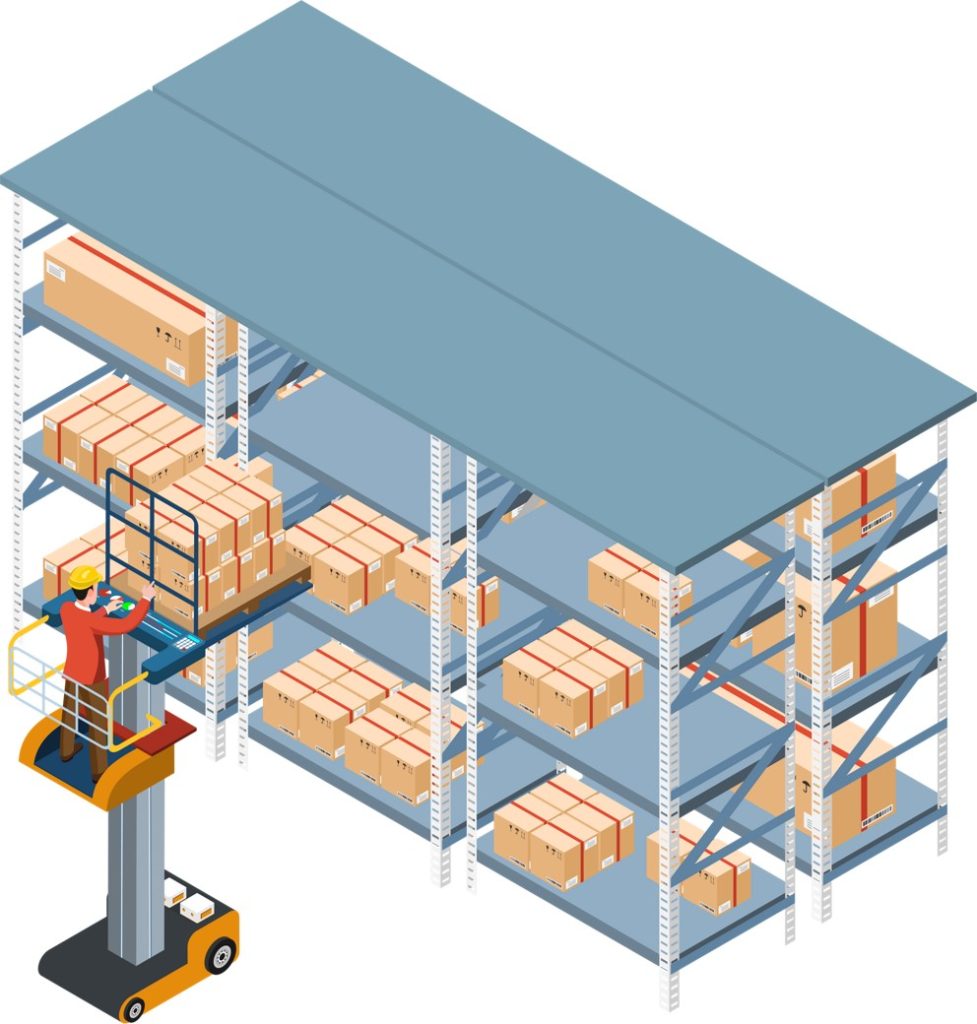

Electric order picker is an important piece of equipment for modern warehouse management. They are designed to lift operators to high-bay shelves for quick and accurate pick-up. Unlike traditional forklifts, these machines focus more on vertical operations. And they are well suited to warehouses with high shelves and narrow aisles. There are many types of order pickers, such as battery-powered fully electric order pickers (electric forward and backward, electric lifting and lowering), and semi-electric models that combine manual and electric functions (manual forward and backward, electric lifting, relatively economical).

Electric order picker can reach a lifting height of up to 157 inches (4 meters), and the load capacity is usually between 440 and 660 pounds (200~300KG), which can flexibly handle everything from light goods to large items. Electric models usually have simple controls and compact designs, suitable for operation in narrow spaces. These features ensure that operators can work efficiently, reduce pickup time, and improve overall cargo handling efficiency.

Importance of electric order pickers in today’s market

The market demand for an electric order picker is not a temporary trend, but a feedback from the booming logistics industry. Global material handling market to grow 5%+ CAGR over next decade. Electric order pickers hold a large share of this market.Analysts forecast over $40B by 2030, driven by warehouse demands. For buyers, this growth points to a clear need: scalable, efficient equipment is no longer optional.

E-commerce is the primary factor driving this demand. As online shopping grows, warehouses are faced with optimizing the use of every square foot of space. Electric order pickers meet this need by quickly picking items from high-level shelves and maximizing vertical space. Logistics centers also rely on these machines to meet just-in-time delivery requirements. Their growing popularity highlights a simple fact: in a market where speed and precision determine success or failure, electric order pickers are a necessary tool to stay competitive.

Market Trends Driving the Evolution of Electric Order Pickers

As warehouses strive to meet growing demand, electric order picker configurations are evolving. Automation is a major trend, and some electric order pickers now integrate AI-driven navigation systems to simplify picking routes. Imagine operators guided by real-time data, minimizing errors and reducing pick-up time, and these machines can be synchronized with warehouse management systems for seamless inventory tracking. This means investing in equipment that not only moves goods, but also operates warehouse systems intelligently.

Sustainability is another key trend. Energy-saving batteries power modern electric order pickers, reducing operating costs while complying with environmental initiatives – a win-win for both budgets and corporate responsibility.

Key Benefits of Electric Order Pickers for Warehouse Operations

Investing in electric order pickers not only improves overall warehouse efficiency, but also saves labor costs and improves accuracy.

Electric order pickers speed inventory retrieval, ease high-level work, cut handling time and errors.Electric order pickers’ precise control lets quick item location, aiding high shelves over slow, manpower-heavy traditional methods.

Improving work safety is also a major benefit of electric order pickers. Compared with manual high-level pick-ups, using electric order pickers reduces the risk of falls. The stable platform and guardrail design of the equipment can protect the safety of operators when working at heights. In addition, automated features such as intelligent path planning can reduce equipment collisions and cargo damage, further reducing operational risks.

From a cost perspective, electric order pickers can optimize space utilization – efficient use of shelves means that warehouses can increase inventory capacity without expanding floor space, saving rental and site costs. In the long run, the durability and low maintenance requirements of the equipment (such as the long battery life of electric models) can also reduce the total cost of ownership and provide a better return on investment for purchasing decisions.

Conclusion

Electric order pickers are important equipment for improving efficiency in modern warehouses. It solves the new challenges of the e-commerce and logistics industries through efficient picking, space optimization and technological innovation. Whether it is to cope with current order growth or to prepare for future automation and sustainable development, electric order pickers are a strategic investment that can drive warehouse competitiveness.