Hydraulic pallet jacks usually use an integrally casting cylinder, which makes it beautiful, sturdy and durable. Uses a chrome-plated piston rod and internal overflow valve for overload protection and descent speed control.

Hydraulic Pallet Jacks Features

Except above chracteristics, its valve core is an integral design, so the cost of maintenance is relatively low. These features make hydraulic pallet jacks particularly suitable for those occasions, where horizontal transportation is required but the space is crowded.

The capacity is generally from 2000kg (4400lb) to 5000kg(11000lb). And the width of the working channel is generally between 2.3 meters and 2.8 meters. Of course, you can choose the model that best suits you according to different working conditions.

The Key Points When Purchasing a Pallet Jacks

First, the width of the fork

You can choose the appropriate fork width according to the size of the pallet you use daily.

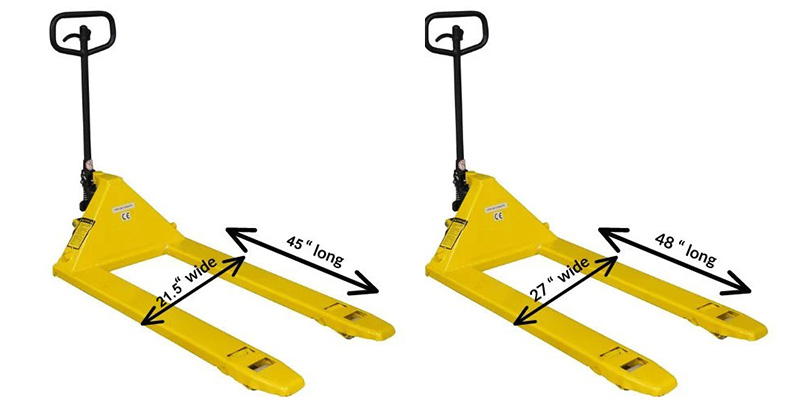

Generally speaking, hydraulic pallet jacks have two standard sizes: wide and narrow, which are 685x1220mm(27×48”) for wide trucks and 550x1150mm (21.5×45”) for narrow trucks.

It also depends on the pallets size your warehouse use. If your pallet size is 1000x1200mm (39×48”), you need choose a size of 27×48”. While if you your pallet size is 550x1150mm, you need choose 550×1150(21.5×45”).

Second : the Capacity

The load capacity of hydraulic pallet jacks generally has 4 international standard: 2000KG(4400LB), 2500KG(5500LB) ,3000KG(6600LB) and 5000kg (11000lb). You can choose the appropriate load capacity according to your needs.

Third:Lifting Height of Fork

he lifting height of the fork is one of the important factors to consider when purchasing a hydraulic pallet jacks. According to the national standard, the height of the pallet is generally 100mm, so the minimum height of the hydraulic pallet jacks is of course lower than this standard

In general, the height of the hydraulic pallet jacks at the lowest point can be divided into two types: 85mm and 75mm (in north America, Vietnam, usually 75mm).

Of course, there are also special low-release manual hydraulic trucks, whose minimum height can even reach 35mm. However, this low-release model is slightly more expensive, and it is not recommended to buy it unless you have special needs. In addition, the fork steel plate of the low-profile vehicle is relatively thin, so its maximum load can only reach 1000 or 1500kg (2200lb to 3300lb)

Fourth: wheel material

When purchasing a When purchasing a manual hydraulic truck, you also need to consider the wheel material. The choice of wheel material should be determined according to the conditions of the workplace.

If the ground condition is poor, you can choose nylon wheels, which are more wear-resistant and cheap.

However, if you want to reduce damage to the ground, or the ground condition is smooth and well, it is best choose polyurethane wheels (PU wheels).Because nylon wheels are relatively hard, while polyurethane wheels are relatively soft and have less impact on the ground., you also need to consider the wheel material.