Industrial sites that search for how to use a drum stacker usually handle heavy, hazardous, or high-value liquids every day. This article explains the full workflow for drum stacker operation, from equipment types and capacity limits to safe lifting, transport, and stacking procedures.

You will see how different drum stacker designs, control layouts, and stability rules affect daily handling tasks, including work with pallets, racks, and mixed storage zones. The safety section links common hazards, OSHA-style inspection practices, and modern digital tools to practical risk controls. The final summary turns these points into clear rules for safe, efficient use of drum stacker in demanding facilities.

Drum Stacker Types And Core Functions

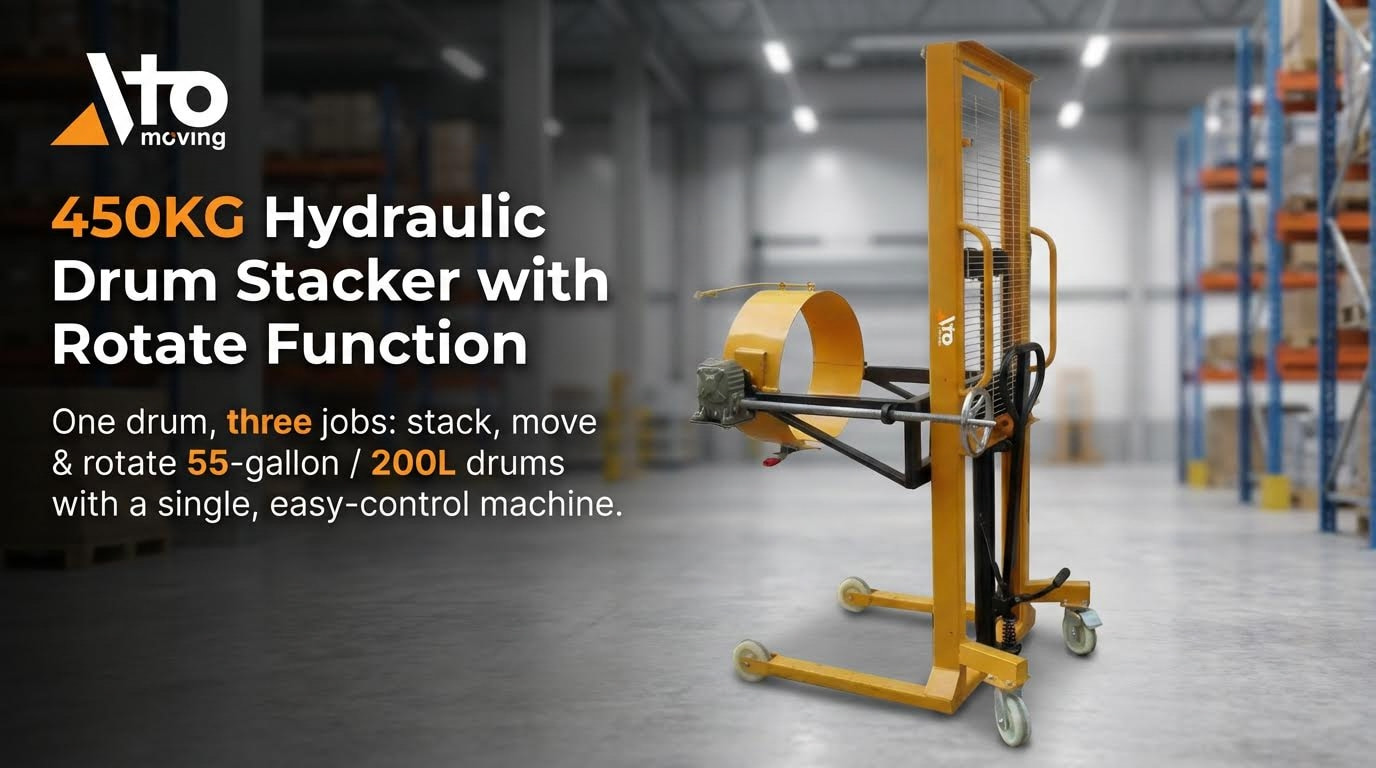

Understanding drum stacker types is the first step in learning how to use a drum stacker safely and efficiently. Each design handles load weight, lift height, and travel distance in a different way. Correct selection reduces manual handling, improves throughput, and lowers incident rates. This section explains how manual, semi-electric, and electric units work and where each type fits best.

Manual, Semi-Electric, And Electric Stackers

Manual drum stackers use human force for both lifting and travel. Operators pump a hydraulic jack and push or pull the unit. These models suit low-throughput areas, short travel distances, and lighter drums within rated capacity. They demand more effort, so fatigue and speed limits are key concerns.

Semi-electric drum stackers usually combine electric lift with manual travel. The motor powers the mast or drum gripping motion, while the operator still pushes the frame. This design reduces strain during vertical handling but keeps capital cost moderate. It fits loading docks, small warehouses, or batch production lines.

Electric drum stackers use powered drive and powered lift. They handle frequent cycles, long aisles, and higher racking systems. Electric units support stricter speed control, better fine positioning, and smoother acceleration. They are the preferred choice when planning standardized procedures for how to use a drum stacker in multi-shift operations.

Key Components And Control Interfaces

Most drum stackers share several core components that define performance and safety. Typical assemblies include:

- Chassis and wheels or castors for support and steering.

- Mast or lifting column with hydraulic or electro-hydraulic system.

- Drum handling attachment such as clamps, hooks, or V-saddle.

- Power source, usually manual pump, battery, or mains-fed charger.

Control interfaces depend on the power level. Manual units often use a foot pedal or tiller-mounted pump handle and a simple release valve. Semi-electric and electric models add push buttons for lift and lower, plus direction switches or tiller heads for travel. Clear labeling of lift, lower, and emergency stop functions is critical for new operators learning how to use a drum stacker.

Good design separates travel controls from mast controls to avoid accidental operation. Many powered units use key switches or access codes for authorized use only. Indicator lights for battery status and fault alarms support routine safety checks and reduce unexpected downtime.

Capacity Ratings And Stability Limits

Safe drum stacking depends on matching capacity ratings with real loads. Key ratings include:

- Maximum load mass in kilograms at a defined load center.

- Maximum lift height for that rated load.

- Allowable tilt or offset when using specific drum attachments.

Engineers define stability using the position of the combined center of gravity. As lift height increases, the stability margin decreases. Rough or sloped floors further reduce this margin. Operators must keep drums close to the mast, avoid sudden turns, and travel with the load as low as practical.

Manufacturers usually publish de-rated capacities for higher lift points or extended attachments. Operators should never guess these limits. Instead, they should read the nameplate and manual before deciding how to use a drum stacker for a new task. Exceeding ratings can cause tipping, loss of drum control, and structural damage to the stacker frame or mast.

Facilities should document site-specific rules that link capacity charts with real drum types, such as 200 litre steel or plastic drums. This approach helps supervisors convert generic ratings into clear, practical instructions at the worksite.

Step-By-Step Drum Stacker Operating Procedures

Operators who search for how to use a drum stacker need clear, repeatable steps. A structured procedure reduces damage to drums, protects people, and keeps workflows efficient. This section explains preparation, lifting, travel, stacking, and shutdown sequences for manual, semi-electric, and electric drum stackers. It focuses on real plant conditions such as mixed pallets, racks, and shared traffic routes.

Pre-Use Area And Drum Preparation

Start with the work area. The floor must be hard, level, clean, and dry. Remove debris, loose packaging, and spill residues. Confirm clear walkways and turning space for the stacker.

Inspect the stacker before each shift. Check forks, drum clamps, and hydraulic lines for damage or leaks. Verify wheels roll freely and the parking brake holds. On powered units, confirm battery charge, cable condition, and emergency stop function.

Then inspect each drum. Look for dents at the chime, bulging, corrosion, or leaking bungs. Reject damaged or leaking drums from stacking operations. Confirm drum type, fill level, and approximate mass. Ensure the drum weight stays within the stacker rating and within floor or rack load limits.

Finally, prepare the storage location. Confirm the planned stack height, rack beam rating, and required aisle width. Check that incompatible chemicals will not sit in adjacent bays.

Correct Drum Lifting, Transport, And Stacking

When learning how to use a drum stacker, the lift sequence is critical. Position the stacker square to the drum. Keep the mast vertical. Approach slowly until the clamp or cradle aligns with the drum centerline.

Engage the grip according to the mechanism design. For hook or jaw types, raise or lower until the hooks sit under the drum rim. Then close or lock the clamp. For band or cradle types, wrap fully around the drum body. Always perform a small test lift a few centimetres off the floor. Check that the drum stays stable and does not rotate or slip.

During travel, keep the drum as low as practical, usually below knee height. Drive at walking speed or slower. Avoid sudden starts, stops, or turns. Never allow anyone to walk under or in front of a suspended drum.

At the stack, stop before the final position. Align the drum with the target spot. Raise only when stationary. Place the drum gently on the pallet, rack, or floor. Release the clamp slowly while watching for movement. Back the stacker straight out before turning.

Working With Pallets, Racks, And Mixed Storage

Work with pallets, racks, and floor storage in a planned way. Random placement creates unstable stacks and blocked aisles. For pallet work, check pallet integrity first. Replace cracked deck boards or broken stringers. Confirm pallet capacity is suitable for the total drum mass.

Typical good practice keeps drums in uniform patterns on pallets. Avoid overhang at pallet edges. Place heavier drums on the lowest level. Keep the pallet surface flat so the drum chimes bear evenly. When stacking pallets of drums, verify combined height against sprinkler clearance and mast reach.

For racks, confirm beam spacing and rated load. Use rack beams that fully support the pallet or dedicated drum saddles. Avoid placing bare drums directly on narrow beams. Ensure the stacker mast and overhead guards clear the rack bracing during lifting.

Mixed storage demands clear rules. Separate empty and full drums. Mark zones for flammable, corrosive, and inert products. Maintain minimum aisle widths for both stackers and forklifts. Use traffic plans and signage so vehicles and pedestrians do not cross in blind spots.

Shutdown, Parking, And Securing The Stacker

End-of-task steps are part of safe how to use a electric drum stacker procedures. Never leave a drum suspended. Always lower the load fully to a stable support before shutdown. Open clamps or jaws completely so they cannot trap a drum if the unit moves.

Park the stacker on a level, protected area away from traffic routes, doors, and emergency exits. Lower the mast and attachments to the floor. Apply the parking brake. On powered units, switch off the main power and remove the key if fitted.

For electric stackers, connect the charger according to the manufacturer instructions. Check that cables do not create a trip hazard. Record any defects found during the shift in the maintenance log. Tag out units that have leaks, structural damage, or control faults.

Finally, tidy the operating zone. Remove stray pallets, chocks, and spill kits from travel paths. Confirm that stacked drums remain stable and that access routes stay open for inspections and emergency response.

Safety Checks, Hazards, And Risk Controls

Safe operation starts before the operator touches the controls. Anyone learning how to use a drum stacker must treat inspections, hazard awareness, and risk controls as part of the job, not extra work. This section explains daily checks, typical incident triggers, safe stacking layouts, and how digital tools can reinforce discipline. The goal is fewer near misses, stable stacks, and predictable equipment behavior.

Daily Inspection And Preventive Maintenance

Daily checks answer a core question for supervisors and operators: is this stacker safe to run today. Visual and functional inspections catch leaks, loose parts, and control faults before a load is lifted. This habit is central to safe use of any manual, semi-electric, or electric drum stacker.

Key daily inspection points usually include:

- Structure: mast, frame, forks, and drum grab for cracks, deformation, or missing fasteners.

- Hydraulics: cylinders, hoses, and fittings for leaks, damage, or unusual noise during lift.

- Drive and steering: wheels, brakes, steering linkage, and parking brake function.

- Controls and safety devices: lift / lower controls, emergency stop, horn, alarms, and limit switches.

Operators should verify rating plates and warning labels remain readable. They should also confirm the capacity marking matches the planned drum weights and lift height. Any defect that affects lifting, steering, or braking requires immediate lockout and reporting. Planned maintenance then handles fluid changes, lubrication, and detailed component checks on a weekly, monthly, or usage-based schedule.

Common Operating Hazards And Near-Miss Triggers

Most incidents with drum stackers follow repeating patterns. Understanding these patterns helps teams decide how to use a drum stacker without drifting into unsafe habits. Near-miss reports, CCTV reviews, and job hazard analyses often show the same triggers.

Frequent hazard categories include:

| Hazard | Typical Trigger | Primary Risk |

|---|---|---|

| Overload | Ignoring capacity plate or mixed drum weights | Tip-over, dropped drum |

| Unstable surface | Ruts, slopes, wet or oily floors | Loss of control, sideways slip |

| Poor visibility | High load, cluttered aisles, low lighting | Pedestrian impact, rack strike |

| Unauthorized use | Untrained staff driving “for a quick move” | Incorrect controls, panic actions |

| Unsafe speed | Rushing, no traffic rules, no horn use | Collisions, crushed feet or hands |

Operators must never walk or allow others under raised drums. They should avoid sharp turns with a raised drum and must not travel with the mast extended higher than needed. Handling drums with unknown contents or damaged shells also increases risk, especially with flammable or corrosive liquids.

Safe Drum Stacking Patterns And Storage Layouts

Safe stacking depends on both the drum stacker and the storage plan. Poor layouts force operators into tight turns, blind entries, and awkward placements. Good layouts guide how to use a drum stacker in a repeatable, low-risk pattern.

Important layout and stacking rules include:

- Use flat, clean, dry, and strong floors with known load ratings.

- Keep clear aisles for turning and passing, with marked pedestrian routes.

- Place incompatible chemicals in separate zones with clear labels.

- Respect rack and pallet capacity ratings, including point loads from drum rims.

Stacking patterns should favor stability over density. Column or interlocked patterns on pallets or in racks work better than improvised piles. Drums should sit fully supported, with no overhang. Empty drums can be nested, but only in areas with low traffic and clear signage. Storage zones should include spill kits, ventilation, and lighting suitable for the materials stored.

Using Digital Tools And AI For Safer Operations

Digital tools now support daily decisions around drum stacker use. Video analytics, telematics, and simple mobile checklists help operators and supervisors enforce rules in real time. These tools do not replace training, but they reduce blind spots and missed warnings.

Practical applications include:

- Digital pre-use checklists that block task start until inspection items are confirmed.

- AI video analysis that flags speeding, close calls with pedestrians, or operations in restricted zones.

- Location tracking that records where drums are stored, stack heights, and time in each zone.

Data from these systems can feed safety meetings and toolbox talks. Teams can review actual behavior, not just written procedures, and adjust routes, signage, or training. Over time, this feedback loop lowers incident rates and supports continuous improvement in drum stacker operations.

Summary: Safe, Efficient Use Of Drum Stackers

Safe, efficient drum stacker use depends on clear procedures, trained operators, and controlled work areas. Facilities that search for how to use a drum stacker need a full view of equipment types, operating steps, and hazard controls. This article linked stacker selection, daily checks, and storage layouts into one practical framework. It also showed how digital tools and AI can support safer drum handling in busy plants.

Key findings are simple. Operators must know stacker capacity, drum weight, and floor limits before lifting. Pre-use checks of hydraulics, structure, and brakes reduce failure risk. Stable, clean, and marked travel routes cut collision and tip hazards. Correct stacking patterns and compatible drum groupings improve long-term stability and inspection access.

Industry trends point to more electric and semi-electric units, tighter integration with warehouse traffic plans, and wider use of vision or sensor systems for real-time alerts. Plants should plan for data logging of inspections, near-miss events, and overload attempts to refine rules over time. AI video analytics already helped identify speeding, close passes, and unsafe stacking zones.

For practical roll-out, sites should standardize one written procedure per stacker type, link it to job hazard analysis, and enforce pre-shift inspections. Training must cover both manual controls and emergency actions, including hydraulic failure and spill response. A balanced view accepts that advanced stackers and software reduce risk but never replace conservative loads, disciplined housekeeping, and strict access control.