Operations searching how to lift extra long pallet safely must balance stability, capacity, and throughput. This article explains the fundamentals of fork positioning, entry depth, and load center control for long pallets, then compares key attachments such as wide load stabilisers, fork extensions, and slip-sheet systems.

You will see how to match forklifts, straddle carriers, and reach stackers to extra-long loads, and how storage design, pallet flow, and racking influence safe handling. The final section turns engineering guidance into practical checklists and key takeaways so safety, maintenance, and operations teams can align on one robust standard for long-pallet handling.

Fundamentals Of Fork Positioning For Long Pallets

Operations that ask how to lift extra long pallet safely must control fork entry depth, load center, and alignment. Incorrect fork positioning multiplied over long spans increases deflection, pallet damage, and tip-over risk. This section explains how to set forks for extra-long pallets, how to engage them cleanly, and which positioning errors cause the most incidents.

Fork Entry Depth, Load Center, And Stability

Extra-long pallets amplify the effect of poor fork entry. The longer the pallet, the more bending and twisting occur if forks sit too shallow. For safe handling, forks should enter as close to full pallet depth as possible. As a rule of thumb, aim for 100% insertion, with 80% as the minimum.

When planning how to lift extra long pallet loads, treat fork entry depth and load center as linked. Shallow entry pushes the effective load center forward, beyond the rating on the capacity plate. Most counterbalance forklifts were rated at a 600 mm load center. Long pallets and overhanging loads can move the center of gravity far beyond this if forks do not support the rear deck boards.

| Parameter | Typical requirement |

|---|---|

| Fork entry depth | 80–100% of pallet depth |

| Rated load center | Commonly 600 mm |

| Fork condition | No cracks, bends, or >10% wear |

| Pallet support | Front and rear deck boards fully supported |

Extra-long pallets often flex. Full-depth fork entry reduces this flex and spreads load into the mast evenly. Operators should stop and reinsert if they see pallet bowing, twisting, or deck boards lifting before the load leaves the ground.

Aligning, Leveling, And Engaging Extra-Long Pallets

Clean engagement is central to any method for how to lift extra long pallet loads. The operator should approach square to the pallet face, with mast centered on the load width. Small angular errors at the tips become large skew across a long pallet.

Before entry, forks should sit level and at the correct height for the entry openings. Enter slowly until forks reach full depth or the 80% minimum. The operator should pause, confirm that both tips are fully under the load, then raise only enough to clear the ground. A slight rear tilt then locks the load against the backrest.

For very long or flexible pallets, multi-point support becomes important. Where possible, use wider fork spacing or additional supporting points to cut mid-span deflection. In tight aisles, supervisors should define standard pallet orientations so operators always approach from the most stable side.

Simple visual aids help. Painted floor lines, pallet stop blocks, and fork-tip markers guide consistent fork depth and alignment. These low-cost controls support both safety and productivity when handling long loads at height.

Common Fork Positioning Errors And How To Avoid Them

Most incidents involving how to lift extra long pallet loads trace back to repeatable errors. Typical issues include partial fork entry, one fork deeper than the other, and forks set too narrow or too wide. Each error shifts the center of gravity and twists the pallet.

Key errors and controls include:

- Partial entry: Forks stop short of 80% depth. Fix by using depth markers on forks and mandatory recheck before lift.

- Uneven fork depth: One fork fully in, one shallow. Fix by enforcing square approach and using side-shift or fork positioner to re-center.

- Incorrect fork spread: Forks too close or too wide for deck boards. Fix by standard fork spacing guides for each pallet type.

- Angled entry: Forks enter while steering. Fix by requiring straight approach before entry and no steering under load.

Supervisors should link these errors to clear visual symptoms. Examples include skewed pallets on the forks, one side higher than the other, or visible sag between fork blades. Short toolbox talks that show real photos of good and bad positioning help operators correct habits.

Refresher training should focus on long-pallet scenarios, not only standard pallets. Drills can time how long operators take to align, fully enter, and lift without alarms or load shift. This approach improves both safety and cycle time, supporting higher pallet touches per hour without extra equipment.

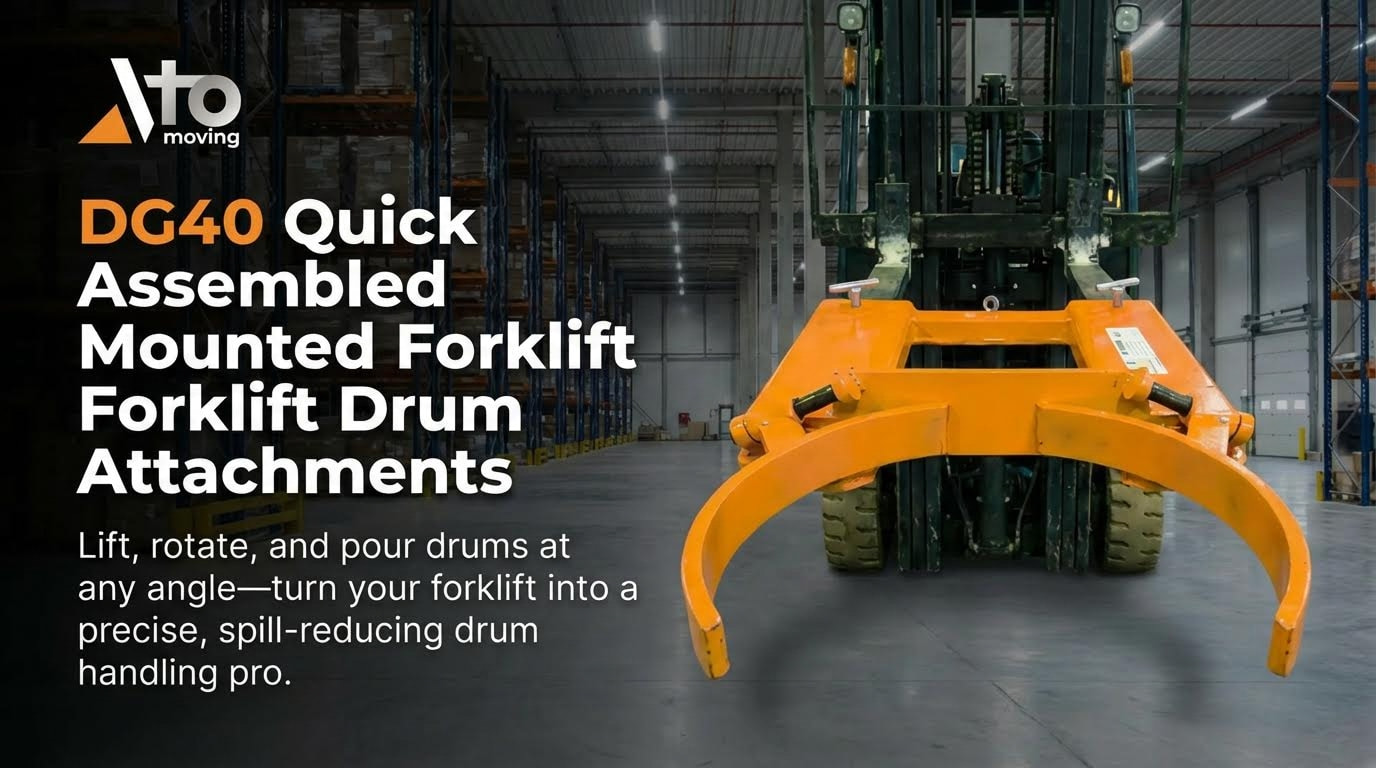

Attachments For Oversized And Extra-Long Loads

Attachments are central to any plan for how to lift extra long pallet loads safely. They increase support points, move the load centre, and change the rated capacity of the truck. Engineers must treat every attachment as a structural change, not an accessory. Correct selection and approval reduce tipover risk and product damage on very long pallets.

Wide Load Stabilisers And Multi-Point Support

Wide load stabilisers help when a pallet is much wider or longer than the fork carriage. They keep the original forks but add outer support arms or forks. This spreads the load over a larger span and cuts bending and twist on the pallet deck. For extra-long pallets, this multi-point support limits mid-span deflection and keeps the centre of gravity closer to the mast.

Engineers should define the number and spacing of support points from pallet drawings and load stiffness. Typical practice is to use at least three to four pick points for long, flexible loads. With very long pallets, stabilisers reduce the chance of one fork punching through a weak board. When planning how to lift extra long pallet loads, combine stabilisers with clear limits on speed, tilt, and travel over uneven ground.

Fork Extensions, Positioners, And Slip-Sheet Systems

Fork extensions are a common answer when standard forks are too short for the pallet length. They must never exceed the base fork length by more than a defined ratio from the manufacturer. Longer forks move the effective load centre forward, so engineers must recalc capacity using the new horizontal distance. Operators should still aim for at least 80% fork entry depth into the pallet to keep the load stable.

Fork positioners let operators change fork spacing from the cab. This helps when handling mixed-width or extra-long pallets without repeated manual adjustments. Correct spacing keeps each fork under strong deck boards or stringers instead of weak gaps. Slip-sheet systems replace pallets completely and use a push-pull attachment, but they are rarely ideal for heavy, very long loads because edge clamping can create high local stresses.

When deciding how to lift extra long pallet loads, compare three options: longer forks, extensions, or a dedicated long-fork truck. A simple table in the risk assessment should cover load length, weight, stiffness, and required lift height. The final choice must respect the combined truck and attachment rating and the minimum fork entry depth target.

Capacity Plates, Engineering Approval, And Compliance

Any attachment that changes the load centre or mass requires a new capacity plate. The plate must show the rated capacity at the new load centre and at the maximum lift height. This is critical for extra-long pallets because the centre of gravity often sits far beyond the standard 600 millimetre reference. Without updated data, operators may unknowingly overload the truck when lifting high or tilting back.

Standards required written approval from the truck manufacturer for modifications that affect capacity or safe operation. If this is not possible, a qualified professional engineer could approve the change after a documented stability and strength review. The engineer would check mast, carriage, and axle loads with the attachment fitted. For compliant long-pallet handling, site procedures should state that operators may only use attachments that appear on the current capacity plate.

Compliance checks should link directly to the site’s risk assessment for how to lift extra long pallet loads. Audits can sample trucks in use and confirm that the visible attachment matches the plate. Any mismatch should trigger an immediate stop and engineering review. This simple control prevents silent capacity loss when attachments are swapped between trucks.

Inspection, Maintenance, And Operator Training Needs

Attachments for long pallets add more welds, pins, and sliding parts that need regular checks. Daily inspections should look for bent arms, cracked welds, loose locking pins, and hydraulic leaks. Load-bearing plates and fork sleeves need close attention at high-stress corners. If thickness loss exceeds typical limits, such as 10% wear on forks, the component should be removed from service.

Planned maintenance should follow the attachment maker’s schedule for lubrication, bolt torque checks, and hydraulic service. For sites that often handle extra-long pallets, maintenance teams should track faults by attachment type. Repeated issues like cracked extensions or deformed stabiliser arms may show that loads are too long, too heavy, or lifted with poor fork entry depth.

Operator training must explain how attachments change truck behaviour. Courses should cover new blind spots, longer overhang, wider swing paths, and slower stopping distances. Instructors need to stress the 80% or better fork entry rule when showing how to lift extra long pallet loads. Refresher training is essential whenever a new attachment type enters the fleet. Clear, simple visual guides at loading points help operators match the right attachment to each long pallet pattern.

Choosing The Right Equipment For Extra-Long Pallets

Operations that ask how to lift extra long pallet safely must match equipment to load geometry, travel distance, and surface conditions. The choice between forklifts, straddle carriers, and reach stackers affects stability, storage density, and cycle time. Racking and pallet flow design also control how far forks must enter and how often operators handle overhanging loads. Modern digital tools then close the loop with monitoring, predictive maintenance, and safety controls.

Comparing Forklifts, Straddle Carriers, And Reach Stackers

Forklifts suit short intra-warehouse moves and moderate pallet lengths when operators can insert forks at least 80% of pallet depth. They work best on flat floors with well-designed aisles and consistent pallet quality. For very long packs or bundles, forklifts often need wide load stabilisers or fork extensions plus strict capacity checks.

Straddle carriers handle extra-long pallets and bundles that sit between their legs, not cantilevered in front. This geometry keeps the center of gravity low and between the wheels, which improves stability on rougher ground and longer routes. They are efficient for repetitive runs of 200–800 metres where long loads move from production to yard or ship.

Reach stackers fit mixed yards with shorter hauls and good pavement. They can lift long pallets or steel packs using multi-point frames or spreaders but rely on well-controlled surfaces and wind limits. When deciding how to lift extra long pallet with these machines, engineers should compare: maximum pallet length, typical load mass, pick-point spacing, and turning space. A simple matrix that scores each option on stability, manoeuvrability, and throughput helps standardise selection.

Racking, Pallet Flow, And Storage Design For Long Loads

Storage design often decides whether a site can lift extra-long pallets with standard forklifts or must invest in specialised carriers. Bulk stacking of long pallets wastes vertical space and creates honeycombing, because lanes must clear before restocking. It also limits safe stack height to avoid damage and instability.

Cantilever racking suits long items but needs wide aisles and careful fork approach. Split-roller pallet flow systems provide higher density for long pallets while keeping first-in/first-out rotation. Engineers set rail spacing, support positions, and separator settings based on pallet length and weight so forks can still achieve near-full entry depth at the picking face.

When planning how to lift extra long pallet into or out of racks, consider:

- Required fork entry depth at each level

- Clearances for mast tilt and fork extensions

- Deflection of long pallets between supports

- Aisle width for chosen truck type

Drive-in or drive-through racks increase density but reduce selectivity and demand precise truck control with long loads. Cantilever and pallet flow designs typically give a better balance between density, access, and damage control for oversized pallets.

Digital Tools, Predictive Maintenance, And Safety Systems

Digital systems help answer how to lift extra long pallet consistently across shifts and sites. Warehouse management systems can assign long pallets to suitable zones, restrict them to equipment with adequate capacity, and optimise slotting to cut empty travel. Travel-path analysis and slotting tools have increased picks per hour and reduced distance per pallet in typical warehouses.

Telematics and operator dashboards track impacts, overload events, and unsafe fork positioning. Sites use these metrics to coach operators, standardise fork entry practices, and reduce product damage. For long pallets, sensors that monitor mast tilt, height, and load position give early warnings before stability margins are exceeded.

Predictive maintenance platforms analyse truck usage, lift cycles, and battery data. They schedule service outside peak windows and reduce unplanned downtime. For fleets that handle extra-long pallets, this avoids scenarios where only the specialised long-load unit fails and the yard stalls. Integrated safety systems, including speed limits in racking, geofenced no-go zones, and wind alarms in outdoor yards, complete the control framework for long-pallet handling.

Summary And Key Takeaways For Safe Long-Pallet Handling

Safe practice for how to lift extra long pallet loads depended on basic fork setup, correct attachments, and matched equipment. Operations that handled long pallets safely treated fork entry depth, load center, and support span as hard engineering limits, not operator preference.

Technically, the core rules were simple. Forks had to enter as deep as possible, with 80% of pallet depth as the minimum and full depth preferred. The shifted load center on extra-long pallets reduced rated capacity fast, especially when operators used fork extensions or wide stabilisers. Sites that updated capacity plates after adding attachments and sought engineering approval for changes kept tipover risk under control.

On the equipment side, teams chose between forklifts, straddle carriers, and reach stackers based on haul distance, yard surface, and load geometry. Extra-long pallets often needed multi-point support, pallet flow or cantilever-style storage, and clear ground bearing checks along travel routes. Digital tools, from WMS-driven slotting to condition monitoring, supported higher throughput without pushing operators into unsafe shortcuts.

Looking ahead, facilities that wanted a robust answer to how to lift extra long pallet loads focused on three things. They standardised pallet designs and lift points, invested in the right mix of attachments and carriers, and embedded training, inspection, and data-driven maintenance into daily work. This balanced approach kept productivity gains aligned with stable loads, predictable handling, and defensible compliance records.

Frequently Asked Questions

What equipment can be used to lift extra long pallets?

To handle extra long pallets, you can use specialized material handling equipment designed for oversized loads. Some options include:

- Reach Trucks: These are ideal for narrow aisles and can lift taller and longer loads safely.

- Pedestrian Stackers: Suitable for lifting and moving long pallets in smaller spaces.

- Low Lift Pallet Trucks: For moving long pallets at ground level without needing a forklift.

Choosing the right equipment depends on the dimensions of the pallet and the workspace layout. Forklift Alternatives Guide.

How should operators safely handle extra long pallets?

When handling extra long pallets, safety is critical to prevent accidents or damage. Follow these guidelines:

- Ensure the load is balanced and secured before lifting.

- Use equipment rated for the weight and length of the pallet.

- Avoid twisting your back or overreaching while manually adjusting the pallet.

- If manual lifting is necessary, always have two people lift together to distribute the weight evenly.

For safe practices, refer to general safety recommendations from organizations like OSHA. Proper Lifting Techniques.