Facilities that search for how to safely stack 55 gallon metal drums need clear, practical rules that engineers, safety teams, and operators can all apply. This guide explains how drum geometry, mass, regulations, and hazard controls shape safe stack heights, patterns, and layouts for metal drums in real plants and warehouses.

You will see how inspection routines, mechanical handling methods, and vertical stacking limits work together to prevent leaks, collapses, and blocked exits. The article also compares floor stacking, racking, and high-density flow systems, and reviews emerging tools such as compact drum stackers and smart monitoring. The final section condenses these points into a concise set of best practices that support compliant, efficient stacking of 55-gallon metal drums.

Engineering And Regulatory Basics For Drum Stacking

This section explains the engineering and compliance basics behind how to safely stack 55 gallon metal drums. It links drum geometry and load paths with OSHA, EPA, DOT, and FM rules that control layout, height limits, and containment. Readers see how hazard labels, PPE, and sump sizing work together to keep stacked drum storage stable, inspectable, and compliant.

Drum Geometry, Mass, And Load Path Fundamentals

Standard 55-gallon metal drums are about 0.58 metres in diameter and 0.89 metres high. Empty drum mass is modest, but a full drum can weigh roughly 180 to 360 kilograms depending on the liquid. When you plan how to safely stack 55 gallon metal drums, you must trace the load path from the drum chimes into pallets, dunnage, and the floor slab.

The circular shell carries hoop stress, while the top and bottom chimes act as narrow bearing rings. Point contact between chimes and uneven timber can create high local stress and denting. Flat, stiff dunnage spreads load and keeps chimes aligned so vertical forces pass straight down without tilt. Engineers also check centre of gravity height, since small horizontal impacts from forklifts can create overturning moments on tall or slender stacks.

Key layout checks usually include:

- Drum condition: no deep dents, heavy corrosion, or bulging heads.

- Pallet rating: total drum mass within pallet and rack limits.

- Floor capacity: slab bearing pressure within design values.

- Symmetry: drums arranged in tight, even patterns.

Stable stacks rely on uniform drum dimensions, consistent fill levels, and restrained bases so horizontal loads do not cause progressive lean.

OSHA, EPA, DOT, And FM Requirements Overview

OSHA material handling rules require stacked materials to be stable and self-supporting. For 55-gallon drums this means blocked or chocked bases, interlocked rows where possible, and height limits that allow safe inspection. Guidance has discouraged stacks above two drums high because container strength and condition vary and access often needs ladders.

DOT regulations control packaging, closure integrity, and marking for drums used in transport. Drums must meet design codes, use proper bungs or lids, and carry clear hazard markings before shipment. EPA rules focus on preventing releases of hazardous substances during storage and handling. Facilities must inspect drums for leaks, maintain labels, and provide secondary containment sized for worst credible spills.

Factory Mutual guidance adds more conservative criteria for insured properties. FM-certified drum storage buildings have defined fire protection features and larger sump capacities than minimum EPA values. Across all agencies, common themes appear: know the contents, keep access routes clear, control ignition sources, and prevent stack collapse. Engineering design for drum stacking should document how layouts meet or exceed each applicable rule set.

Hazard Classification, Labeling, And PPE Requirements

Safe stacking starts with clear knowledge of what each drum contains. Hazard classification under transport and workplace systems identifies flammable, corrosive, toxic, or reactive contents. Operators must be able to read labels before they move or stack drums. Unlabeled or damaged labels signal a stop point until the material is identified.

Labels should remain visible even after stacking. This affects drum orientation and row depth. Drums hidden more than two wide in a row can block label access and delay emergency response. Facilities normally align label faces toward aisles to support quick checks for leaks, corrosion, or bulging heads.

PPE selection depends on the hazard class. Typical controls include:

- Chemical-resistant gloves for corrosive or toxic liquids.

- Safety glasses or face shields to protect from splashes.

- Safety footwear to reduce crush risk during handling.

- Respiratory protection where vapours or dusts may form.

Training links labels, safety data sheets, and PPE rules so operators understand why specific gear is required. When planning how to safely stack 55 gallon metal drums, managers should embed label checks and PPE verification into standard operating procedures and pre-lift checklists.

Spill Containment Sump Sizing And Layout

Secondary containment is the final barrier if a stacked drum leaks or fails. For hazardous liquids, EPA guidance has required sump capacity of at least 10% of the total stored volume or one full drum, whichever is larger. Factory Mutual criteria are stricter, calling for 25% of total volume or the largest container, whichever is greater, in many insured facilities.

For example, a bay with 40 drums holds about 8,360 litres. Under EPA rules, minimum sump capacity would be about 836 litres or one drum volume. Under FM guidance, the target would rise to roughly 2,090 litres. Designers usually round up and add freeboard for fire water or rainfall in outdoor systems.

Layout also matters. Good practice includes:

- Placing drums inside continuous sumps or on grated platforms that drain into a common basin.

- Keeping sumps clear of debris so leaked liquid stays contained.

- Locating aisles and doors above sump edges to prevent trip hazards.

- Ensuring forklift barrel dumper wheels do not damage sump walls or grating.

Containment zones should align with stack limits and hazard segregation rules. Flammable drums often need separate sumps from oxidizers or incompatible chemicals. When engineers answer how to safely stack 55 gallon metal drums, they should show that a single drum rupture in the highest stack cannot overwhelm the designed containment volume or escape to drains or soil.

Safe Handling, Inspection, And Stacking Procedures

This section explains how to safely stack 55 gallon metal drums in daily operations. It links inspection, mechanical handling, stacking geometry, and aisle planning into one practical workflow. The goal is stable stacks, quick inspections, and full compliance with safety rules.

Pre-Handling Inspection For Damage, Bulging, And Leaks

Inspection always comes before movement. A full 55-gallon drum can weigh 180 to 360 kilograms, so a missed defect can create serious risk. Operators should walk around each drum and check three zones: shell, chime, and closure. Look for dents, deep scratches, corrosion, or weld cracks on the shell and chimes.

Check lids or bungs for proper fit and intact gaskets. A bulging lid or distorted bung can signal internal pressure or chemical reaction. Treat these drums as high risk and escalate to site safety or hazardous waste specialists. Never move a drum with unknown contents or missing labels.

During inspection, verify that hazard labels, UN numbers, and handling pictograms are present and readable. If labels are damaged or gone, treat the drum as hazardous until identified. Inspect the floor area for staining or residue that may indicate a slow leak. Record defects and tag unsafe drums so they are not moved by mistake.

Mechanical Handling: Forklifts, Dollies, Cranes, And Stackers

Manual handling of 55-gallon drums is unsafe and inefficient. The mass and geometry of the drum increase the chance of back injury and loss of control. Mechanical equipment provides controlled lifting, rotation, and placement. Selection depends on travel distance, aisle width, and stack height.

Forklifts are common for palletized drums. Use drum clamps or dedicated attachments instead of bare forks whenever possible. Drum dollies work well for short moves on smooth floors and single-drum tasks. In tight or congested areas, overhead hoists or drum cranes allow vertical lifting without side clearance.

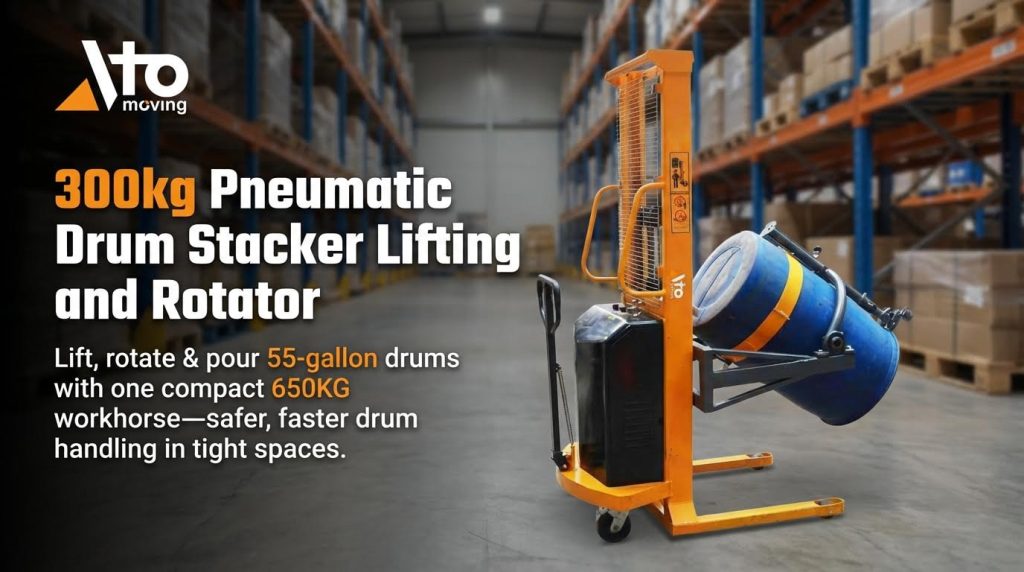

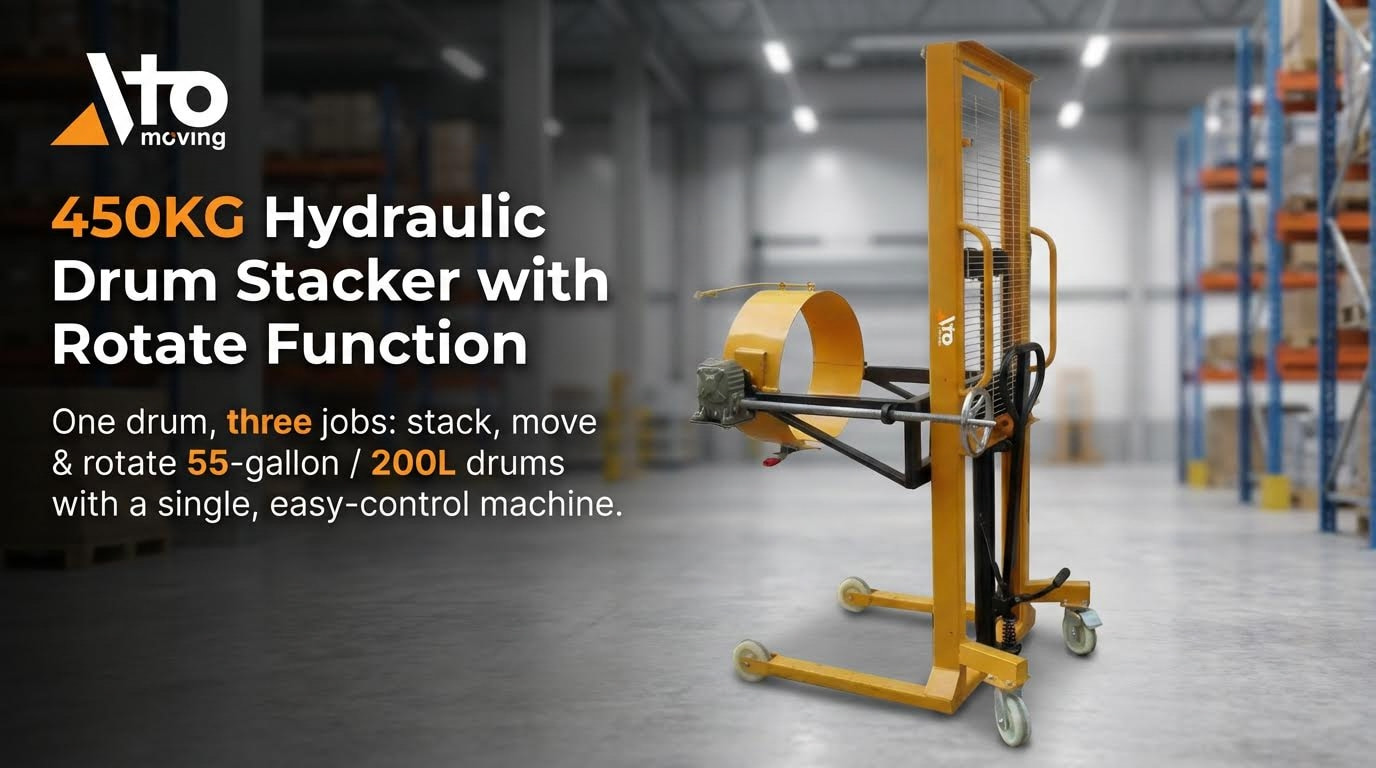

Compact drum stackers are useful where operators must place drums into racking or second tiers with precision. These machines reduce impact loads and allow fine control of drum elevation and tilt. Whatever the equipment, operators must receive task-specific training and wear suitable PPE for the drum contents. Keep clear travel paths and never use drums as work platforms or steps.

Vertical Stacking Limits, Patterns, And Chocking Methods

Safe stacking of 55-gallon metal drums depends on controlled load paths and repeatable patterns. Most guidance discourages stacks higher than two drums because container condition and strength can vary. Higher stacks also make inspection difficult and force the use of ladders. For floor stacking, a common limit is two drums high and two drums wide per row to keep every drum visible.

Drums should sit on level, solid foundations such as pallets or concrete slabs. Stack drums symmetrically so vertical load passes through the drum centerlines. Avoid mixed pallet patterns, such as three-drum and four-drum pallets in the same stack, because this creates uneven support. When stacking more than one tier, place planks, plywood sheets, or pallets between tiers to spread the load and create a flat bearing surface.

Chocking stops horizontal movement. Chock or block the bottom tier on both sides when drums stand on end in multi-tier stacks. When drums lie on their sides, block the bottom course to stop rolling before adding upper tiers. Inspect chocks and dunnage for damage or contamination during housekeeping rounds. Replace crushed or oil-soaked wood, because it can lose friction and allow creep over time.

Aisle Clearances, Access, And Inspection-Friendly Layouts

Aisle design is a core part of how to safely stack 55 gallon metal drums. Good layouts keep every drum visible and reachable without moving other drums. Rows wider than two drums tend to hide interior drums and slow leak detection. Keep rows to two drums wide and two drums high where possible. This geometry supports quick walk-by inspection and fast access in an emergency.

Aisle width must match the turning radius and load envelope of the handling equipment. Forklifts usually need wider aisles than drum dollies or drum stackers, especially when rotating pallets. Do not park or stage drums in front of doors, exits, or emergency equipment. Mark travel lanes, no-storage zones, and stack limits with floor paint or post striping.

Good layouts also consider fire protection and ventilation. Maintain clearances to walls, partitions, and sprinkler heads as required by local codes. Place high-hazard materials closer to exits and away from high-traffic routes when possible. Keep inspection checklists at entry points to drum storage zones so supervisors can verify aisle conditions during routine rounds.

Storage System Design And Emerging Technologies

Storage system design strongly affects how to safely stack 55 gallon metal drums. Engineers must match layout, equipment, and monitoring to drum geometry, mass, and hazard class. Modern systems use racking, flow racks, compact stackers, and digital tools to raise density while keeping risk low.

Floor Stacking Vs. Racking And Flow Rack Solutions

Floor stacking uses direct contact between drums and the slab. It suits small inventories and low hazard products. However, floor stacks usually limit height to two drums to keep inspection access and stability. Wider than two drums per row makes leak checks difficult and raises collapse risk.

Static pallet racking lifts drums off the floor and controls load paths. It allows clear aisles and fixed pick faces. Engineers verify beam and frame capacity against pallet loads that can exceed 1 400 kilograms with four full drums. Deflection limits and anchor design must match local codes and expected impact loads.

Flow rack solutions use full-width rollers or cradles to support each drum. Full roller beds give near continuous support under the chimes and shell. This reduces point loads and dent risk. Typical drum flow lanes use large diameter rollers on close centers with a small pitch, such as about 12 millimetres per 300 millimetres of run, to keep speed low and predictable.

When planning layout, designers compare options on key points: footprint, clear height, inspection access, and evacuation routes. Floor stacking uses the lowest capital cost but the most floor area per drum. Racking and flow racks need higher investment but support better segregation of incompatible chemicals and clearer escape paths.

Push-Back Roller Systems For High-Density Drum Storage

Push-back roller systems allow drums or drum pallets to sit in deep lanes on inclined rollers. The forklift loads from one face and pushes earlier loads back. This creates a Last In First Out pattern. It fits stable products that do not require strict First In First Out rotation.

Engineering tests showed that well designed push-back lanes move drums at safe, steady speeds. Large rollers on close centers spread the load from the drum chimes. Typical industrial rollers carry between 40 and 160 kilograms each. Total lane ratings must exceed the mass of fully loaded pallets in the deepest position with a safety factor.

Ramp stops at the pick face capture the leading pallet or drum. They prevent roll out when the forklift backs away. The truck controls the rate of flow by backing out slowly. This usually removes the need for extra speed controllers in shallow lanes, such as two deep arrangements.

Push-back systems increase storage density compared with single deep racking or floor stacks. Lanes can reach several pallets deep and multiple levels high. However, designers must check that fire protection, egress, and inspection rules still work. For hazardous liquids, clear sight lines to each drum row and access for leak response remain essential.

Compact Drum Stackers And Ergonomic Handling Equipment

Compact drum stackers help operators place 55 gallon metal drums into tight rack openings or narrow aisles. They reduce manual pushing and rolling, which lowers strain and crush risk. Many designs use adjustable gripping arms to handle different drum diameters and heights.

Battery powered stackers support smooth lifting and fine positioning. They allow controlled acceleration and deceleration, which protects drum integrity and rack structures. A battery status display helps supervisors plan charging and avoid mid shift downtime. Heavy duty frames and masts resist bending from repeated high mass lifting cycles.

Ergonomic features focus on low effort control. Short throw levers, well placed handles, and clear sight lines reduce operator fatigue. This supports consistent application of safe stacking rules, such as placing drums square on pallets and avoiding overhang. In cramped rooms, walk behind stackers often outperform forklifts because they need smaller turning radii.

When choosing equipment, safety managers consider several points: rated capacity, lift height, compatibility with pallets and racks, and surface conditions. They also review how the stacker will interact with other systems, such as flow racks or containment curbs. Proper training and pre use checks complete the safe handling chain.

Digital Twins, Predictive Maintenance, And Smart Monitoring

Digital twins model the storage area, racks, and drum stacks in a virtual space. Engineers use these models to test how to safely stack 55 gallon metal drums under different layouts. They can simulate aisle widths, evacuation routes, and sprinkler shadowing before any hardware install.

Sensors on racks, stackers, or floors can feed live data into these models. Load cells, tilt sensors, and position encoders help detect overloads or misaligned pallets. Predictive maintenance tools then flag rollers, bearings, or welds that show abnormal patterns. This reduces the chance of a mechanical failure that could drop a drum.

Smart monitoring also tracks drum locations and age. It links barcodes or RFID tags to hazard classes and compatibility rules. Software can block operators from placing incompatible chemicals in the same bay or above each other. It can also enforce stacking limits by warning when a rack level reaches its planned capacity.

These technologies do not replace basic engineering controls. They add a layer of verification and documentation. For facilities with large drum counts or mixed hazard classes, digital tools support tighter control of risk, faster audits, and better response when leaks or structural alarms appear.

Summary Of Best Practices For Safe Drum Stacking

Safe facilities treat every 55-gallon drum as a heavy, potentially hazardous pressure vessel. A single drum can weigh 180 kilograms or more, so layout, handling, and inspection standards must work together. When engineers ask how to safely stack 55 gallon metal drums, they should combine regulatory rules with simple, repeatable shop-floor routines.

Technical best practices start with inspection. Check each drum for dents, rust, bulging ends, missing bungs, and unreadable labels before storage. Treat unlabeled drums as hazardous until identified. Reject damaged or pressurized drums from stacked storage and isolate them for specialist handling.

Stacking design follows clear limits. Keep free-standing rows no higher than two drums and no more than two drums deep to keep every drum visible. Use pallets, planks, or plywood between tiers to spread the load. Chock the bottom tier to stop movement. Keep stacks stable, self-supporting, and outside exit paths and emergency routes.

Handling practice focuses on mechanical aids. Use forklifts, drum dollies, hoists, or compact drum stackers instead of manual pushing or rolling. Train operators on hazard classes, PPE, and emergency actions. Mark maximum stack heights on posts or walls for quick visual checks.

Looking ahead, dense storage systems and smart monitoring will support safer drum stacking. Floor and rack systems with full support surfaces improve stability and reduce point loads. Digital tools will help track locations, stack heights, inspection status, and near-miss trends. These advances will not remove the need for conservative heights, good housekeeping, and disciplined inspections, but they will make consistent compliance easier.