Facilities that ask how many drum spill pallets do I need must balance regulations, layout, and handling methods. This article walks through the full engineering logic from regulatory volume rules to pallet quantity calculations for drums and IBCs.

You will see how EPA, OSHA, SPCC, REACH, and ADR containment criteria drive minimum sump volumes and how inspectors verify those numbers on site. A step‑by‑step section then links drum inventory, fill levels, and pallet configurations so you can size secondary containment with clear, repeatable formulas.

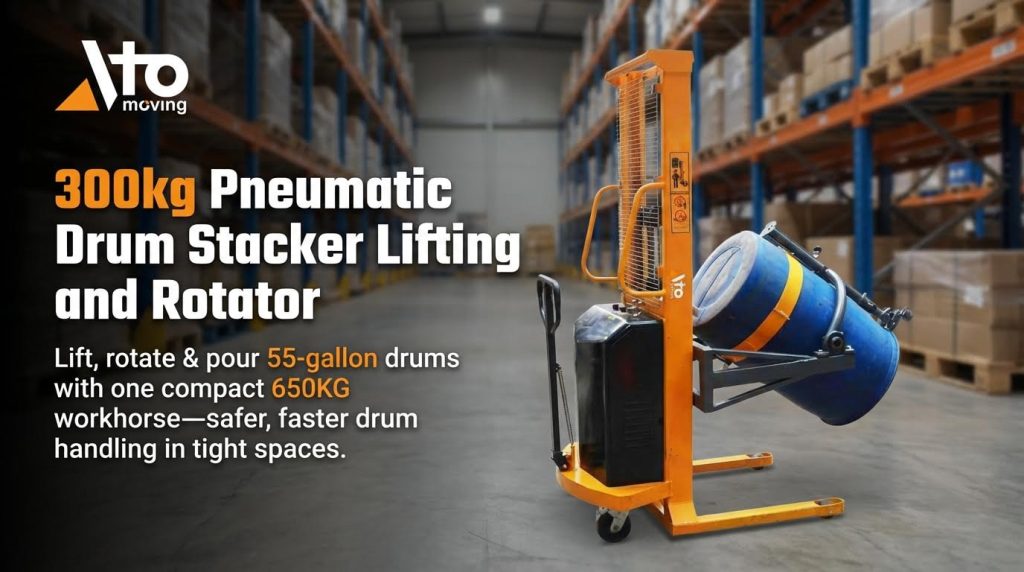

Later sections address indoor versus outdoor layouts, forklift, AGV, and cobot handling limits, and the role of digital twins and AI in keeping storage plans compliant over the full lifecycle. The conclusion distills practical, engineer‑focused guidance so EHS, operations, and design teams can agree on a robust, auditable spill pallet sizing standard, supported by solutions such as semi electric order picker and walkie pallet truck systems where appropriate.

Key Regulations And Containment Volume Rules

Engineers asking “how many drum spill pallets do I need” must start from the legal containment rules. Capacity, not only drum count, drives pallet sizing and layout. This section explains the main US and EU frameworks and how inspectors check volume. It gives you a clear basis for later sizing calculations and equipment choices.

EPA, OSHA, SPCC, REACH, ADR Basics

Spill pallets existed to give secondary containment for drums and IBCs. In the United States, three pillars guided design work.

- EPA rules, including SPCC, set secondary containment capacity and discharge prevention goals.

- OSHA standards focused on safe handling, stability, and worker protection around stored liquids.

- Water and waste rules such as NPDES and RCRA addressed releases to soil and drains.

In Europe, REACH controlled chemicals, while ADR covered transport of dangerous goods. Member states then added local storage rules and fire codes. Across both regions, regulators expected spill pallets to capture leaks, overfills, and hose failures. When you estimate how many drum spill pallets you need, you must satisfy the strictest rule that applies on your site.

10% Or Largest-Container Rule Explained

The most common sizing rule used a simple capacity test. Secondary containment must hold at least:

- 10% of the total stored liquid volume, or

- 100% of the volume of the largest single container,

- whichever value is greater.

For drum storage, you first convert each drum or IBC to litres. Then you sum the inventory and apply the rule. The result is the minimum sump capacity that your spill pallets and bunds must provide. This rule answered the core question “how many drum spill pallets do I need” from a volume angle, not only from a footprint angle. Engineers often added a safety margin to cover rainwater, foam discharge, or future extra drums.

Differences Between US And EU Volume Criteria

US and EU rules looked similar but not identical. In the US, the 10% or largest-container rule was dominant for many facilities under EPA programs. Some states or fire codes added extra limits for flammables or indoor storage. In the EU, authorities often required 110% of the largest container volume for a storage area. This higher factor covered both catastrophic failure and firefighting water. For mixed drum and IBC storage, the largest IBC usually governed the design. When you plan how many drum spill pallets you need for a global site portfolio, you must design for the toughest applicable criterion, usually the EU 110% rule.

How Inspections Evaluate Containment Capacity

Inspectors did not only count pallets. They checked whether the installed system could actually hold the required spill volume. Typical checks included:

- Comparing drum and IBC inventory against documented containment calculations.

- Verifying rated sump volume from data plates or certificates on the pallets.

- Looking for rainwater, sludge, or debris that reduced usable capacity.

- Confirming pallets sat on level, undamaged floors with no hidden drains.

They also reviewed chemical compatibility between stored liquids and pallet materials. If drums exceeded pallet load ratings, inspectors could deem the system unsafe. From an engineering view, the practical answer to “how many drum spill pallets do I need” became: enough pallets, with verified sump volume and load rating, to meet the worst-case spill plus operational margins, even on the rainiest or busiest day of the year. For instance, using a manual pallet jack or a hydraulic pallet truck can help ensure proper handling during inspections. Additionally, equipment like a drum transporter ensures safe movement of drums, reducing the risk of spills.

Step-By-Step Pallet Quantity Calculations

Engineers who ask how many drum spill pallets do I need must follow a clear calculation path. The answer depends on drum inventory, liquid volume, containment rules, and pallet geometry. This section breaks the task into simple engineering steps. It supports quick checks during design, audits, and expansion projects.

Define Drum Inventory, Sizes, And Fill Levels

The first step is to fix the inventory baseline. List every drum, IBC, or small container that will stand on spill pallets. Separate containers by size class and liquid type if segregation is required.

For each group define:

- Container type and nominal volume, for example 200 litre drum or 1 000 litre IBC.

- Typical fill level as a fraction of nominal volume.

- Maximum credible fill level used for safety calculations, usually 100%.

- Expected inventory range, such as minimum, normal, and peak counts.

Use the worst case inventory for the question “how many drum spill pallets do I need”. That avoids under‑sizing when production peaks or deliveries bunch together. Keep units consistent in litres or cubic metres to avoid errors.

Calculate Required Secondary Containment Volume

The second step is to convert inventory into a minimum containment volume. In the United States, engineers usually applied the rule “at least 10% of total volume or 100% of the largest container, whichever is greater”. In the European Union, rules often required 110% of the largest container for similar applications.

Use this simple sequence:

- Convert each container volume to litres if needed.

- Compute total stored volume Vtotal.

- Find largest single container volume Vmax.

- Compute 10% of Vtotal (or local percentage value).

- Required containment Vreq = max(percentage of Vtotal, Vmax or 1.1×Vmax in the EU).

Use Vreq as the design target for the sum of pallet sump volumes in the area. Apply the rule to each logical containment zone, not only the full site.

Match Drum Count To Pallet Configurations

Once you know Vreq and the drum count, you can answer “how many drum spill pallets do I need” in physical units. The task has two checks. First, every drum must sit on a pallet position. Second, the total sump capacity must meet or exceed Vreq.

Use a short method:

- Select standard pallet sizes, for example 1‑drum, 2‑drum, or 4‑drum units.

- Divide total drum count by pallet drum capacity to get a minimum pallet count.

- Round up to the next whole pallet and adjust for layout or aisle rules.

- Add the sump capacities of the chosen pallets and compare with Vreq.

If the total sump volume is below Vreq, either add one more pallet or choose units with larger sumps. Check forklift barrel grabber access, door widths, and racking before locking in the configuration. Engineers often run two or three options to balance floor space, handling time, and cost.

Worked Examples For Drums And IBCs

Worked examples help turn the abstract question “how many drum spill pallets do I need” into a repeatable method.

Example 1: 200 litre drums

A facility stores 12 drums of 200 litres each.

- Total volume Vtotal = 12 × 200 = 2 400 litres.

- Vmax = 200 litres.

- 10% of Vtotal = 240 litres.

- Vreq = max(240, 200) = 240 litres.

- Use three 4‑drum pallets to hold 12 drums.

- Check that combined sump capacity of the three pallets is at least 240 litres.

Example 2: Mixed IBCs and drums

A mixing area holds two 1 000 litre IBCs and four 200 litre drums.

- Vtotal = 2 × 1 000 + 4 × 200 = 2 800 litres.

- Vmax = 1 000 litres.

- 10% of Vtotal = 280 litres.

- Vreq in the US style rule = 1 000 litres.

- Vreq in EU style rule ≈ 1 100 litres.

One IBC pallet with a sump above 1 100 litres can cover all six containers in a single bunded area if layout and risk studies allow. If operations need separation, split the inventory across two pallets and check each zone against the rule. This stepwise method lets engineers defend their answer whenever auditors ask how they sized drum spill pallet quantities.

Layout, Handling, And Lifecycle Considerations

Engineers who ask “how many drum spill pallets do I need” cannot size only by volume. Layout, handling method, and lifecycle costs also control the final pallet count. This section links containment calculations to real plant constraints so designs stay compliant and workable through years of operation.

Indoor Vs Outdoor Storage And Weather Impacts

Indoor storage usually gives more control over containment performance. Floors stay level and dry, so sump capacity remains available for actual spills. Indoor locations also reduce UV aging of plastic pallets and help keep steel pallets dry and corrosion free.

Outdoor storage changes how many drum spill pallets you need in practice. Rain and snow can fill open sumps and steal useful volume. When that happens, the effective containment capacity drops below the design value. To stay compliant, engineers either add extra pallets or use covers and shelters.

Key checks for outdoor layouts include:

- Is the pallet under a roof or weather cover?

- Can rainwater be drained or pumped without releasing chemicals?

- Is the base firm enough to prevent tilt or settlement?

Cold climates also affect drum handling. Ice on grating reduces grip and increases drop risk. Thermal cycling ages seals and welds. Periodic inspections and conservative loading plans help offset these effects.

Forklift, AGV, And Cobot Handling Constraints

When you calculate how many drum spill pallets you need, you must respect handling limits. A perfect containment layout that blocks forklift routes will fail in operation. Forklifts need clear tine pockets, turning space, and stable approach angles.

For manual and forklift handling, engineers usually check:

- Fork pocket width and height versus truck forks

- Ground clearance for dock plates and ramps

- Rated load of pallet versus four full drums or IBCs

Automated guided vehicles and cobots add new constraints. AGVs follow fixed paths with tight tolerances. They need repeatable pallet positions and clear sensor lines of sight. Cobot drum handlers work best when pallets sit at defined heights and offsets.

If handling is frequent, fewer larger pallets may not be ideal. Smaller units can cut travel distance and reduce partial loads. That can change the answer to “how many drum spill pallets do I need” even when volume is unchanged.

Digital Twins And AI For Layout And Compliance

Digital twins helped engineers test spill pallet layouts before any hardware moved. A digital twin could combine 3D facility geometry, drum inventories, and traffic flows. Engineers used it to compare different pallet sizes, locations, and aisle widths.

AI tools supported quick answers for questions like “how many drum spill pallets do I need this quarter.” Algorithms could:

- Ingest live tank and drum inventory data

- Apply 10% or largest-container rules automatically

- Flag zones where effective sump volume dropped due to rain or residue

Simulation of forklift and AGV paths reduced collision risk and dead zones. The model showed where pallets caused congestion or blocked exits. It also helped position inspection routes and spill kits.

When regulations or production changed, engineers updated the digital twin. The system then recalculated required pallet counts and suggested redistribution instead of new purchases where possible.

Cost, Durability, And Maintenance Trade-Offs

Lifecycle thinking is key when you decide how many drum spill pallets you need to buy now. Initial price is only one part of the picture. Durability, repair options, and inspection time all affect long term cost per stored litre.

Typical trade-offs include:

- Plastic pallets: lighter, corrosion resistant, easier to move, but lower stiffness and more UV sensitive outdoors

- Steel pallets: high strength and temperature resistance, but heavier and more prone to rust without coatings

- Modular systems: flexible layouts, but more joints to inspect and seal

Maintenance plans should define inspection intervals, load test rules, and repair or scrap criteria. Cracked sumps or deformed grates reduce usable containment volume. That can force facilities to add extra pallets just to stay compliant.

Engineers also consider standardization. Using a small set of pallet sizes simplifies spare parts, training, and layout changes. This makes it easier to answer “how many drum spill pallets do I need” when production ramps up or shifts between drum and IBC storage.

Practical Summary And Engineer-Focused Conclusions

Engineers asking “how many drum spill pallets do I need” must link inventory, regulations, and layout into one sizing method. The earlier sections defined regulatory volume rules, step-by-step calculations, and layout constraints for drums and IBCs. This conclusion turns those ideas into a compact checklist that supports design reviews and compliance audits.

Key findings stay consistent across regions. Secondary containment must hold at least 10% of total stored volume or 100% of the largest container. In the European Union, 110% of the largest container applied instead. Typical single to four-drum pallets offered sump volumes from roughly 50 litres to about 300 litres, while IBC pallets exceeded 1 000 litres. These ranges framed realistic engineering options without locking you into one product type.

Industry practice moved toward modular four-drum pallets for 200 litre drums and dedicated IBC pallets for 1 000 litre totes. Digital twins and simple spreadsheet tools already helped teams test “what‑if” cases for future growth, seasonal peaks, and equipment changes. This trend will grow as AI tools link spill risk, pallet capacity, and inspection data.

For practical implementation, engineers should fix a standard method to answer “how many drum spill pallets do I need” in four steps. First, define current and forecast drum and IBC counts with realistic fill levels. Second, calculate the regulatory containment volume using the correct rule set. Third, select pallet sizes so total sump volume clearly exceeds the requirement with margin for rain, sludge, and ageing. Fourth, verify warehouse order picker, AGV, or Atomoving paths, plus inspection access, in the layout model.

Technology will improve materials, monitoring, and automation, but the core engineering task remains stable. You must convert container volume into a defensible containment capacity and then into a clear pallet count. A balanced approach uses conservative safety factors, simple calculation tools, and standardised pallet types. That mix keeps facilities compliant today and flexible enough to adapt to new rules and higher automation tomorrow.