Plants that ask where can i find a supplier of drum handling equipment need a clear, engineering-led sourcing strategy. This article walks through how to define drum types, flows, hazards, and plant requirements before you contact vendors, so you avoid costly mismatches and under‑specified systems.

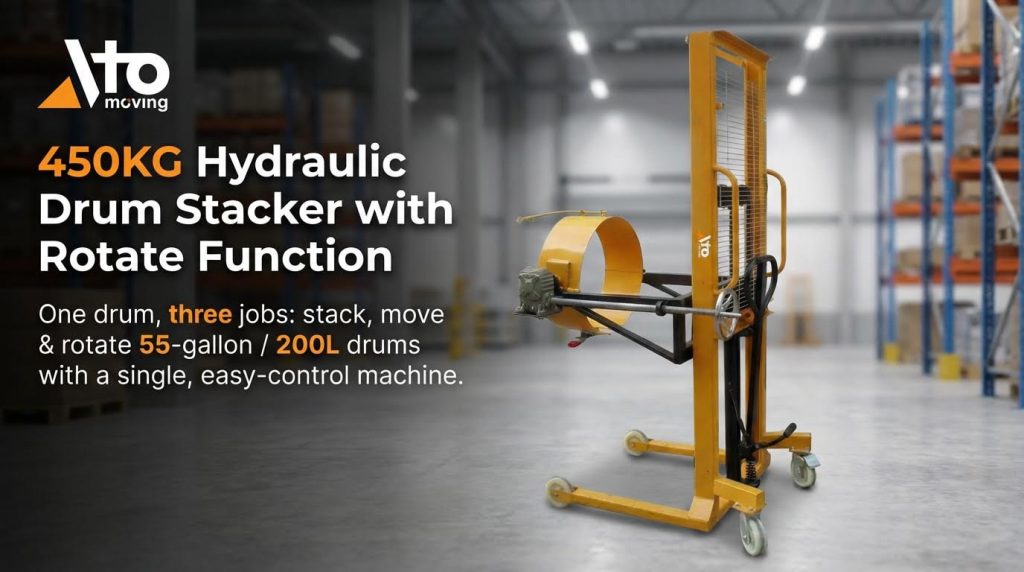

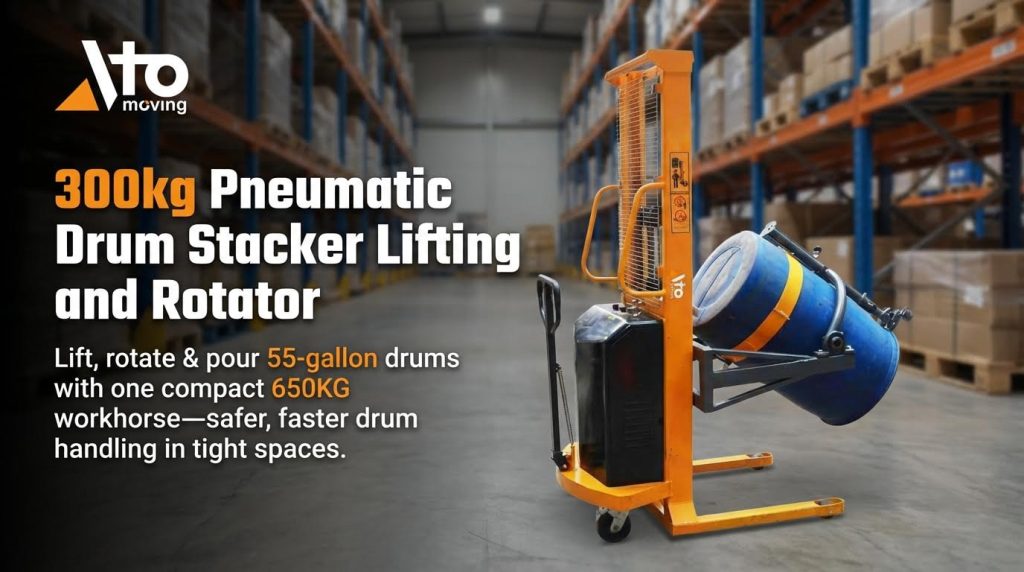

You will see how to evaluate technical capability, duty cycles, lifecycle cost, and integration with layouts and automation. The guide then explains how to assess supplier reliability, risk, digital maturity, and innovation, including qualification processes, audits, and performance scorecards. The final section consolidates these factors into a practical framework for selecting robust, long-term drum handling partners, from basic manual devices to fully automated drum stacker solutions like electric drum stacker and forklift drum grabber double grips.

Define Drum Handling And Plant Requirements

Plant engineers asking where can i find a supplier of drum handling equipment should first define precise requirements. A clear requirement set avoids oversizing, wrong technology choices, and hidden lifecycle costs. This section explains how to map drum flows, set performance and TCO targets, align interfaces, and embed safety and regulatory needs before engaging suppliers.

Map Drum Types, Flows, And Hazard Classes

The starting point is a structured drum inventory and flow map. Define for each stream:

- Drum format: steel, plastic, or fiber; open or tight head; typical mass in kilograms.

- Content type: liquids, powders, viscous materials, or mixed use.

- Flow pattern: receipts per day, internal transfers, staging, and shipping volumes.

- Storage mode: floor stacking, racking, or automated storage.

Classify each stream by hazard class. Use globally harmonized system (GHS) and local rules for flammable, corrosive, toxic, or oxidizing products. For hazardous contents, note temperature limits, venting needs, and grounding or bonding rules. A simple matrix that links drum type, hazard class, and handling task (loading, tipping, mixing, dispensing, palletizing) gives a clear input when you later search where can i find a supplier of drum palletizer equipment that can cover all use cases with one platform.

Specify Performance, Duty Cycle, And TCO Targets

Next define quantitative performance and duty profiles. Key points include:

| Aspect | Typical definition |

|---|---|

| Throughput | Drums per hour per line |

| Operating pattern | Shifts per day and days per year |

| Load spectrum | Minimum and maximum drum mass |

| Environment | Indoor, outdoor, cold room, washdown |

Duty cycle drives technology choice. Light duty (few drums per shift) can use simpler mechanical devices. Heavy duty with 24/7 operation needs robust frames, industrial bearings, and higher protection for drives. When you ask where can i find a supplier of electric drum stacker equipment, you should also request a total cost of ownership view. Include energy use, planned maintenance hours, spare parts cost, and expected service life. Use a comparison sheet that normalizes offers to cost per handled drum over the expected lifetime. This avoids choosing the cheapest offer with the highest downtime.

Interface, Layout, And Automation Integration Needs

Reliable suppliers expect early information about plant interfaces. Document:

- Upstream and downstream equipment: conveyors, palletizers, mixers, filling lines.

- Available space: clear heights, column grids, and door openings.

- Floor data: load rating in kN/m² and slab flatness class.

- Utilities: power, compressed air, data networks, and grounding points.

Define automation level target for each zone. Options range from manual assist devices to semi-automatic cells and fully automatic systems linked to warehouse management systems or manufacturing execution systems. Clarify how operators interact with the system: local push buttons, touch panels, or remote control. When you research where can i find a supplier of drum dolly equipment, look for vendors that can provide layout proposals, 3D models, and simulation of drum flows. These tools expose bottlenecks and collision risks before installation and support faster internal approval.

Safety, Standards, And Regulatory Constraints

Safety and compliance constraints filter the supplier list early. Start with applicable machinery and workplace safety rules in your country or region. Typical areas include guarding, emergency stops, safe access, and noise limits. For hazardous areas, define zoning, gas or dust groups, and temperature classes. This drives selection of motors, sensors, and control hardware. Fire protection rules set limits for stacking heights, aisle widths, and segregation of incompatible chemicals.

Document corporate safety standards as well. Examples include maximum manual lift mass, required safety integrity level for interlocks, and lockout tagout procedures. Environmental and ESG targets also matter. State expectations for energy efficiency, recyclability of materials, and leak containment volumes. When you decide where can i find a supplier of drum handling equipment, check if candidates can show previous projects certified under the same standards and can deliver documentation packages for audits. A clear requirement set shortens technical clarifications, reduces change orders, and leads to safer, more reliable installations.

Evaluate Technical Capability And Product Fit

When teams ask where can i find a supplier of drum handling equipment, technical fit should guide the shortlist. This section explains how to match supplier capability with plant needs, beyond simple price comparisons. It focuses on core technologies, engineering depth, safety performance, and lifecycle support so procurement and engineering can select equipment that runs reliably and safely over years of service.

Core Drum Handling Technologies And Options

Technical screening starts with the supplier’s portfolio breadth. A strong drum handling supplier covers full workflows, from drum infeed to final dispatch. Typical product ranges include:

- Manual and semi-automatic drum trucks, palletizers, and de-palletizers

- Powered drum lifters, tilters, and rotators for filling and emptying

- Conveyor-based drum transport and accumulation systems

- Integrated cells combining conveyors, lifts, and safety fencing

Check whether the supplier supports the specific drum mix in your plant. This includes steel, plastic, and fiber drums, standard 200 litre drums, and any special sizes. Ask for documented performance envelopes. These should state rated capacity, speed, duty class, and compatible drum geometries. Plants that search where can i find a supplier of drum handling equipment should also verify how well the catalog covers hazardous areas, washdown zones, and cold storage applications.

Engineering Depth, Customization, And Simulation

Reliable drum handling projects rarely use catalogue items only. Most plants need layout tweaks, special grippers, or links to existing lines. Supplier engineering depth therefore becomes a key selection filter.

Assess the size and skills of the supplier’s design team. Confirm use of 3D CAD, finite element checks for stressed components, and layout modelling. Ask for previous custom projects with similar drum types, throughputs, and floor constraints. A capable supplier should offer:

- Custom infeed and outfeed heights to match conveyors or mezzanines

- Adapted clamps for damaged or non-standard drums

- Layouts that fit low headroom or narrow aisles

Simulation adds further confidence. Request digital simulations that show throughput, accumulation buffers, and interaction with forklifts or AGVs. These models help quantify bottlenecks and validate that proposed drum handling solutions will meet peak shift demands before hardware is ordered.

Safety Engineering, Ergonomics, And Compliance

Safety performance strongly influences where can i find a supplier of drum handling equipment that is acceptable to EHS teams. Suppliers should design to recognized machinery and workplace standards, and provide clear evidence of compliance. This includes risk assessments, guarding layouts, and interlock logic descriptions.

Key aspects to review include:

| Aspect | What to Verify |

|---|---|

| Machine guarding | Fixed and interlocked guards around pinch, crush, and roll zones |

| Control system | Emergency stops, safety relays or controllers, and safe stop categories |

| Ergonomics | Operator reach distances, handle forces, and visibility of drum edges |

| Documentation | Operating manuals, lockout-tagout procedures, and training materials |

Ergonomic design reduces strain injuries during drum loading, clamping, and release. Ask for data on push/pull forces and typical operator postures. Compliance with local safety rules, plus internal corporate standards, should be contract requirements, not assumptions.

Lifecycle Durability, Maintainability, And Spares

Technical fit also includes how the equipment behaves after five or ten years of use. Plants that ask where can i find a supplier of drum handling equipment really need suppliers that design for high duty cycles and easy maintenance. Request typical design lifetimes for key components such as cylinders, gearboxes, and bearings under defined duty classes.

Evaluate how easily technicians can inspect and service the system. Good designs offer safe access platforms, removable panels, and clear component labelling. Service intervals and task lists should be documented, with estimated durations. Spares support is equally important. Confirm:

- Standardization of motors, sensors, and valves across product families

- Guaranteed spare part availability windows, often 10 years or more

- Regional stock locations and typical lead times for critical parts

Durable finishes, sealed bearings, and protected sensors extend life in harsh drum areas where spills, dust, and corrosion occur. A supplier that treats lifecycle engineering as seriously as initial performance will deliver lower total cost of ownership and less unplanned downtime.

Assess Supplier Reliability, Risk, And Innovation

Engineers who ask where can i find a supplier of drum handling equipment must look beyond catalog data. Reliability, risk, and innovation decide real lifecycle cost and uptime. This section explains how to qualify suppliers so plants avoid chronic downtime, safety incidents, and stalled automation projects.

Financial Health, References, And Site Audits

Financial strength reduces the risk of supply disruption during long projects. Review audited accounts, credit ratings, and ownership structure. Focus on stable revenue, controlled debt, and steady investment in engineering staff and tooling.

References from plants that run similar drum weights, hazard classes, and shift patterns are vital. Ask each reference about uptime, service response time, and how the supplier handled failures or retrofits. Prioritize references with at least three years of operating history on comparable systems.

| Aspect | What to Verify |

|---|---|

| Financial health | 3–5 years of stable figures and ongoing R&D spend |

| Installed base | Number of drum handling lines in your industry |

| References | Documented uptime and maintenance experience |

| Quality system | Certified QMS such as ISO 9001 |

Site audits close the loop. Walk the factory, review welding, machining, and assembly standards, and check test procedures. Confirm that the supplier can stage full FATs with drums, pallets, and controls that mirror your plant.

Digital Tools, AI Maintenance, And IoT Readiness

Digital capability now shapes lifecycle performance more than hardware alone. Ask if the supplier offers condition monitoring for drives, hydraulics, and safety devices. Modern systems usually stream vibration, temperature, and cycle counts to a plant or cloud platform.

AI-based maintenance tools can detect patterns that precede failures. Typical examples include rising motor current on hoists or abnormal speed changes on conveyors. These tools help schedule planned stops instead of reacting to breakdowns.

- Confirm support for standard industrial networks such as Ethernet-based fieldbuses.

- Check if the supplier exposes secure APIs or data tags for your SCADA or MES.

- Review cybersecurity practices for remote access and firmware updates.

Engineers who search where can i find a supplier of drum handling equipment should favor vendors that already integrate with digital maintenance workflows. This lowers integration risk and speeds internal approval from IT and reliability teams.

Sustainability Practices And ESG Compliance

Industrial buyers now treat sustainability as a core risk factor, not a side topic. Drum handling equipment affects energy use, noise, and operator exposure. Suppliers should document how they reduce energy per handled tonne and limit leaks or spills in hazardous areas.

ESG checks start with compliance. Review environmental permits, safety records, and any history of sanctions or serious incidents. For global sourcing, screen the supplier and its key owners against sanction and adverse media lists using recognized tools.

When comparing options, ask for simple, verifiable indicators, such as:

- Use of high-efficiency motors and optimized hydraulic circuits.

- Designs that enable reuse, refurbishment, or modular upgrades.

- Waste, water, and energy reduction programs at their factories.

Supply chains often carried most of a buyer’s environmental footprint. Selecting a supplier with credible ESG reporting reduces future compliance risk and supports corporate sustainability targets.

Contracts, KPIs, And Long-Term Partnership Models

Contract structure converts technical promises into enforceable performance. Define clear scopes for design, installation, commissioning, and training. Tie payment milestones to objective events such as FAT, SAT, and acceptance tests.

Set measurable KPIs that fit drum handling operations. Typical metrics include mechanical availability, mean time to repair, spare part lead time, and safety incident rate. Scorecards and dashboards help track these KPIs after go-live.

| KPI | Purpose |

|---|---|

| Availability (%) | Shows real operating time vs. planned time |

| MTTR | Measures speed of fault recovery |

| Warranty response time | Limits extended downtime |

| Spare parts lead time | Protects against stockouts |

Partnership models can include multi‑year service contracts, upgrade roadmaps, and joint improvement projects. These models encourage both sides to reduce total cost of ownership, not only purchase price. When asking where can i find a supplier of drum handling equipment, shortlist vendors willing to align contracts with performance, not just shipment.

Summary: Selecting Robust Drum Handling Partners

Operations teams asking where can i find a supplier of drum handling equipment need a clear selection framework. The earlier sections defined plant requirements, evaluated technical fit, and assessed supplier risk and innovation. This summary links those steps into a practical decision path that supports safe, efficient drum handling across the full equipment life cycle.

From a technical view, the best partners match drum types, flows, and hazard classes with proven handling technologies. They show engineering depth, credible simulations, and documented compliance with relevant safety and electrical standards. Lifecycle thinking remains central. Buyers should compare total cost of ownership, including energy use, wear parts, downtime exposure, and upgrade paths.

From a reliability view, robust suppliers combine financial stability, clean compliance records, and transparent references. Contracts should embed measurable KPIs for uptime, response time, and spare parts availability. Digital tools, remote diagnostics, and IoT readiness now influence long-term competitiveness, especially for automated drum lines.

Looking ahead, selection criteria will extend beyond price and basic performance. Buyers will weigh ESG metrics, circular economy options, and data-sharing models for predictive maintenance. The most resilient plants will build long-term partnerships, not spot purchases, and will treat supplier selection as a recurring strategic process, updated as regulations and automation technologies evolve. For instance, equipment like the drum stacker, drum lifting equipment, and forklift barrel grabber exemplifies advanced solutions in this domain.